AI-Driven De Novo Enzyme Design: From Algorithm to Application in Biomedical Research

This article provides a comprehensive overview of cutting-edge AI-driven strategies for de novo enzyme design, tailored for researchers, scientists, and drug development professionals.

AI-Driven De Novo Enzyme Design: From Algorithm to Application in Biomedical Research

Abstract

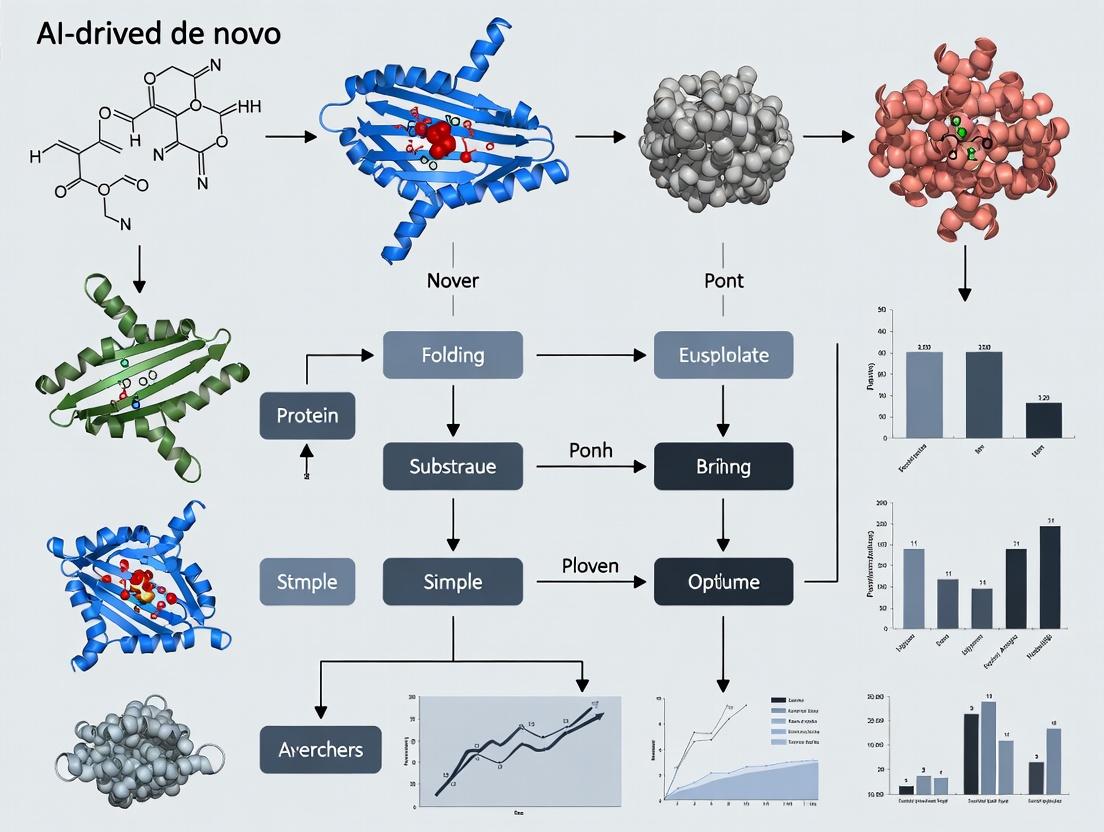

This article provides a comprehensive overview of cutting-edge AI-driven strategies for de novo enzyme design, tailored for researchers, scientists, and drug development professionals. We explore the foundational principles of generative AI models, including protein language models and diffusion-based architectures, that enable the creation of enzymes with novel functions. The scope covers detailed methodologies for training and applying these models, practical troubleshooting and optimization techniques for real-world challenges, and rigorous validation frameworks for assessing designed enzymes. The article synthesizes current capabilities, benchmarks performance against traditional methods, and highlights transformative implications for therapeutic development, biocatalysis, and synthetic biology.

The AI Revolution in Enzyme Engineering: Core Concepts and Computational Foundations

Within the paradigm of AI-driven enzyme design for novel functions, the term "de novo design" has undergone a significant evolution. Historically, it referred to the rational, physics-based construction of biomolecules from scratch, guided by fundamental principles of structural biology and thermodynamics. Today, it is increasingly synonymous with generative artificial intelligence (AI) models that propose entirely novel protein scaffolds and active sites optimized for a target function. This document delineates this transition, providing application notes and detailed protocols for contemporary, AI-integrated de novo enzyme design workflows.

Quantitative Comparison of Design Paradigms

The table below summarizes the core characteristics, data requirements, and typical outputs of the major paradigms in de novo enzyme design.

Table 1: Comparison of De Novo Enzyme Design Paradigms

| Aspect | Rational (Physics-Based) Design | Generative AI-Driven Design |

|---|---|---|

| Primary Driver | First principles (thermodynamics, quantum mechanics), Rosetta, Foldit. | Deep learning on protein structure/sequence landscapes (RFdiffusion, ProteinMPNN, AlphaFold). |

| Core Data Requirement | High-resolution protein structures, force fields, catalytic mechanism details. | Massive datasets of protein sequences (UniProt) and structures (PDB), multiple sequence alignments. |

| Typical Output | A single or small number of carefully optimized candidate sequences. | Thousands of diverse, novel protein backbones and sequences fulfilling geometric constraints. |

| Design Focus | Precise placement of functional residues in a stable, often natural-like, scaffold. | Generation of entirely novel folds and motifs that conform to a user-specified "scaffold" or "motif." |

| Success Rate (Experimental) | Historically low (< 1% for novel catalysis), but high-impact successes. | Dramatically higher initial stability (> 50% express and fold), functional success rates still being quantified. |

| Computational Cost | High per-design (extensive molecular dynamics/energy minimization). | High initial training, but low per-design inference cost. |

| Key Advantage | Deep mechanistic insight, interpretability. | Exploration of vast, uncharted regions of protein space, speed, and diversity. |

Key Research Reagent Solutions

Table 2: Essential Reagents & Materials for AI-Driven De Novo Enzyme Design & Validation

| Reagent / Material | Function / Explanation |

|---|---|

| Generative AI Models (RFdiffusion, Chroma) | Generates novel protein backbone structures conditioned on functional constraints (e.g., symmetric pores, binding sites). |

| Sequence Design Models (ProteinMPNN, ESM-IF1) | Inputs a 3D backbone and outputs optimal, stable amino acid sequences. Critical for "fixing" AI-generated scaffolds. |

| Structure Prediction (AlphaFold2, RoseTTAFold) | Validates the foldability of in silico designs. A high pLDDT score is a prerequisite for experimental testing. |

| Gibson Assembly Cloning Kit | Standard method for assembling linear DNA fragments encoding novel protein sequences into expression vectors. |

| BL21(DE3) E. coli Competent Cells | Standard prokaryotic host for high-yield protein expression of soluble, non-membrane de novo designs. |

| Ni-NTA Agarose Resin | Affinity purification of polyhistidine-tagged designed proteins via FPLC. |

| Size Exclusion Chromatography (SEC) Column (e.g., Superdex 75) | Assesses monomeric state and global folding integrity of purified designs. |

| Differential Scanning Fluorimetry (DSF) Dye (e.g., SYPRO Orange) | High-throughput measurement of protein thermal stability (Tm). |

| Stopped-Flow Spectrophotometer | For rapid kinetic assays of designed enzymatic activity using substrate analogs or natural substrates. |

Experimental Protocols

Protocol 1: GenerativeDe NovoScaffold Design with RFdiffusion

Objective: To generate a novel protein backbone accommodating a predefined functional motif (e.g., a triosephosphate isomerase (TIM) barrel active site).

- Constraint Definition: Define the functional motif using a 3D coordinate file (PDB format). Specify which residues should form the motif and their required relative geometries.

- Model Inference: Run RFdiffusion with the motif specified as a "contiguous" or "partial" motif constraint. Use default parameters for noise scheduling and 100-200 inference steps.

- Generation & Clustering: Generate 1,000-10,000 backbone samples. Cluster the outputs based on Cα root-mean-square deviation (RMSD) to identify unique topological families.

- Initial Filtering: Select top clusters based on RFdiffusion's internal confidence score (pTM prediction) and visual inspection for motif integrity and structural plausibility.

- Sequence Design: Pass 10-20 selected backbones from each promising cluster through ProteinMPNN (with scaffold regions fixed and motif regions allowed to redesign) to generate 128 sequences per backbone.

- In Silico Validation: Predict the structure of all designed sequences using AlphaFold2 (without templates) or AlphaFold3. Filter designs where the predicted structure (highest-ranked model) has a high confidence (pLDDT > 80) and recapitulates the intended backbone geometry (RMSD < 2.0 Å to the design model).

(Title: Generative De Novo Design Workflow)

Protocol 2: Experimental Validation of a Designed Enzyme

Objective: To express, purify, and conduct a preliminary functional assay on a de novo designed enzyme.

Part A: Expression & Purification

- Gene Synthesis & Cloning: Synthesize the DNA sequence (codon-optimized for E. coli) and clone into a pET vector with an N-terminal His6-tag using Gibson assembly. Transform into BL21(DE3) cells.

- Small-Scale Test Expression: Inoculate 5 mL cultures (LB + antibiotic). Grow at 37°C to OD600 ~0.6, induce with 0.5 mM IPTG, and express at 18°C for 16-18 hours.

- Cell Lysis & Clarification: Pellet cells, resuspend in lysis buffer (e.g., 50 mM Tris pH 8.0, 300 mM NaCl, 10 mM imidazole, lysozyme, protease inhibitors). Lyse by sonication. Clarify by centrifugation (20,000 x g, 30 min, 4°C).

- Affinity Purification: Load supernatant onto Ni-NTA resin. Wash with 10 column volumes (CV) of wash buffer (50 mM Tris pH 8.0, 300 mM NaCl, 25 mM imidazole). Elute with elution buffer (same as wash, but 250 mM imidazole).

- Buffer Exchange & SEC: Desalt eluate into assay/gel filtration buffer (e.g., 20 mM HEPES pH 7.5, 150 mM NaCl). Load onto an SEC column (e.g., Superdex 75 Increase) pre-equilibrated in the same buffer. Collect the main symmetric peak.

Part B: Initial Functional Characterization

- Thermal Stability (DSF): In a 96-well plate, mix 20 µL of protein (0.2 mg/mL) with 5 µL of 50X SYPRO Orange dye. Perform a thermal ramp from 25°C to 95°C at 1°C/min in a real-time PCR machine. Calculate Tm from the derivative of the fluorescence curve.

- Activity Screen: Set up a reaction mixture containing assay buffer, putative substrate(s), and purified enzyme. Use a stopped-flow or plate reader to monitor a spectroscopic signal change (absorbance, fluorescence) over time. Compare to negative controls (no enzyme, heat-denatured enzyme).

- Kinetic Analysis: For hits, vary substrate concentration and fit initial velocity data to the Michaelis-Menten equation to obtain kcat and KM.

(Title: Experimental Validation Pipeline)

The field of de novo enzyme design has been fundamentally transformed by generative AI. The transition from purely rational design to hybrid AI/physics approaches, as framed within AI-driven strategies for novel function, represents a leap in capability. The protocols outlined here provide a roadmap for leveraging generative models to create novel enzymes and rigorously testing them in the laboratory, accelerating the discovery of proteins with tailor-made functions for therapeutics and biotechnology.

Application Notes & Protocols in AI-DrivenDe NovoEnzyme Design

This document provides application notes and detailed protocols for three core AI architectures—Protein Language Models (PLMs), Diffusion Models, and Generative Adversarial Networks (GANs)—as applied to de novo enzyme design for novel catalytic functions. The integration of these architectures represents a paradigm shift in computational enzyme engineering, enabling the generation of functional protein sequences and structures not found in nature.

Protein Language Models (ESMFold & AlphaFold) for Enzyme Scaffold Prediction

Application Notes: PLMs like ESMFold and AlphaFold decode the statistical relationships embedded in evolutionary protein sequences to predict 3D structure from primary sequence (ESMFold) or, conversely, to assess sequence likelihood given a structure. In de novo design, they are used to "hallucinate" stable, foldable protein backbones for novel enzyme active sites and to score the "naturalness" of designed sequences.

Key Quantitative Comparison:

Table 1: Comparison of Key Protein Language/Folding Models for Enzyme Design

| Model | Primary Function | Key Input | Design Application | Typical pLDDT/Accuracy | Inference Speed |

|---|---|---|---|---|---|

| AlphaFold2 | Structure Prediction | MSA, Templates | Validate designed structures, generate conditioning inputs | >90 pLDDT for many natural folds | Minutes (GPU) |

| ESMFold | Single-Sequence Structure Prediction | Amino Acid Sequence | Rapid backbone generation & sequence scoring for de novo proteins | ~70-85 pLDDT for novel designs | Seconds (GPU) |

| ProteinMPNN | Sequence Design (Inverse Folding) | Backbone Structure & Context | Generate optimal, foldable sequences for a given backbone | >40% recovery rate on native backbones | Seconds (GPU) |

Protocol 1.1: Validating De Novo Enzyme Backbones with ESMFold

Objective: To assess the foldability and predicted structure of a computationally generated enzyme backbone sequence.

Materials (Research Reagent Solutions):

- Hardware: GPU-enabled workstation (e.g., NVIDIA A100/A6000, 40GB+ VRAM).

- Software: Python 3.9+, PyTorch, ESM repository (Hugging Face

transformersor Meta'sesm). - Input: FASTA file containing the designed amino acid sequence(s).

Procedure:

- Environment Setup: Install ESMFold via pip:

pip install "fair-esm[esmfold]"or load the model from Hugging Facetransformers. - Model Loading: Load the pretrained ESMFold model and its associated tokenizer.

- Sequence Preparation: Input your designed amino acid sequence(s). Remove non-canonical residues.

- Structure Inference: Run inference. The model outputs a PDB-formatted prediction, per-residue confidence scores (pLDDT), and a predicted alignment error (PAE) matrix.

- Analysis: Scrutinize the pLDDT (target >70 overall, >90 for active site residues). Use the PAE to assess predicted domain rigidity and potential misfolding. Visually inspect the predicted structure (e.g., in PyMOL) against the design target for backbone alignment and active site geometry.

Title: ESMFold Validation Workflow for De Novo Sequences

Diffusion Models for Conditional Protein Backbone Generation

Application Notes: Diffusion models, inspired by non-equilibrium thermodynamics, learn to generate data by iteratively denoising random noise. In protein design, they are conditioned on functional specifications (e.g., desired catalytic site coordinates, substrate shape) to generate novel, diverse, and structurally plausible protein backbones tailored for a specific function.

Protocol 2.1: Generating Functional Backbones with RFdiffusion

Objective: To generate de novo protein backbones that contain a user-specified functional motif or binding site geometry.

Materials (Research Reagent Solutions):

- Hardware: High-performance GPU (NVIDIA A100/V100, 32GB+ VRAM recommended).

- Software: RFdiffusion (RosettaFold Diffusion) codebase, PyTorch, conda environment.

- Input: PDB file defining the functional motif (e.g., a set of catalytic residues in specific 3D arrangement).

Procedure:

- Conditioning Setup: Define the "scaffolding" task. Prepare a conditioning file (e.g., a

contigmap.jsonfor RFdiffusion) specifying which parts of the structure are fixed (your motif) and which are to be generated (diffusable). - Model Configuration: Set diffusion parameters: number of denoising steps (e.g., 500), noise schedule, and symmetry options (if designing oligomers).

- Generation Run: Execute the diffusion sampling process. The model starts from noise and gradually denoises, maintaining the conditioned motif while inventing a surrounding, stable fold.

- Output Clustering: Generate hundreds of backbones. Cluster outputs based on structural similarity (e.g., using MMseqs2 or RMSD clustering) to select diverse, high-confidence candidates.

- Downstream Processing: Feed selected backbone candidates into an inverse folding model (e.g., ProteinMPNN) to obtain sequences, followed by ESMFold validation (Protocol 1.1).

Title: Diffusion Model for Conditioned Backbone Generation

Generative Adversarial Networks (GANs) for Sequence & Property Optimization

Application Notes: GANs pit a generator (creates data) against a discriminator (evaluates authenticity). In enzyme design, they can optimize sequences for multiple objectives simultaneously: stability, expressibility, and desired quantum chemical properties (e.g., transition state energy, pKa of key residues), moving beyond purely structural metrics.

Protocol 3.1: Adversarial Optimization of Enzyme Sequences

Objective: To refine a designed enzyme sequence to maximize predicted stability and a target quantum mechanical property using a Wasserstein GAN (WGAN) framework.

Materials (Research Reagent Solutions):

- Hardware: GPU with CUDA support.

- Software: TensorFlow/PyTorch, RDKit (for molecular featureization), ORCA/PySCF (for QM property calculation, or surrogate model).

- Input: Initial seed sequences (from ProteinMPNN), property prediction models.

Procedure:

- Model Architecture: Define Generator (G) as an LSTM/Transformer that outputs amino acid probabilities. Define Critic (D) (in WGAN) that takes a sequence and outputs a scalar score combining "naturalness" and property predictions.

- Property Predictor Training: Train (or load pretrained) surrogate neural networks to predict target properties (e.g., DFT-calculated binding energy of a transition state analog) from sequence or structural features.

- Adversarial Training Loop:

a. Generate: G produces a batch of novel sequences.

b. Evaluate: D scores sequences using a combined loss:

L = D(sequence) + λ * Property_Predictor(sequence), where λ balances realism and function. c. Update Critic: Train D to distinguish high-scoring sequences from low-scoring ones. d. Update Generator: Train G to maximize the score output by D. - Convergence & Sampling: Train until equilibrium. Sample from the generator to obtain sequences predicted to be stable and possess enhanced target properties.

Title: GAN for Multi-Property Sequence Optimization

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Tools for AI-Driven *De Novo Enzyme Design*

| Item / Solution | Function in Workflow | Example/Provider |

|---|---|---|

| GPU Computing Cluster | Accelerates model training (diffusion, GANs) and inference (PLMs). | NVIDIA DGX Station, Cloud (AWS p4d, GCP A2). |

| Protein Language Model APIs | Provides state-of-the-art structure/sequence prediction as a service. | ESMFold (Hugging Face), AlphaFold Server (DeepMind). |

| Inverse Folding Model | Designs optimal sequences for a given 3D backbone structure. | ProteinMPNN, Rosetta fixbb. |

| Quantum Chemistry Software | Computes target electronic properties for training surrogate models in GANs. | ORCA, PySCF, Gaussian. |

| Structural Biology Suite | Visualizes, analyzes, and validates generated 3D models. | PyMOL, ChimeraX, UCSF. |

| High-Throughput Cloning & Expression Kit | Rapid experimental validation of designed enzyme sequences. | Gibson Assembly, Cell-free expression systems (NEB PURExpress). |

Application Notes

The AI-driven de novo enzyme design pipeline is fundamentally dependent on comprehensive, high-quality training data. Structural (Protein Data Bank, PDB) and sequence (UniProt) repositories provide the foundational datasets required for machine learning model development. Their integrated use enables the prediction of tertiary structures from sequence, the identification of functional motifs, and the inference of evolutionary constraints essential for designing novel catalytic functions.

Quantitative Database Metrics and Utility

Table 1: Current Core Database Statistics (2024)

| Database | Primary Content | Total Entries (Approx.) | Key AI-Relevant Features | Primary Use in Enzyme Design |

|---|---|---|---|---|

| Protein Data Bank (PDB) | 3D macromolecular structures (X-ray, Cryo-EM, NMR) | ~220,000 | Coordinates, B-factors, electron density maps, ligands. | Structural templates, active site geometry, ligand-protein interaction maps. |

| UniProt Knowledgebase (UniProtKB) | Protein sequences & functional annotations | ~250 million (Swiss-Prot: ~570,000; TrEMBL: ~249 million) | Curated functional sites, EC numbers, families/domains, variants. | Multiple Sequence Alignments (MSAs), evolutionary couplings, function annotation transfer. |

| UniRef Clusters | Sequence clusters at various identity levels | UniRef90: ~140 million clusters | Non-redundant sequence sets for efficient large-scale analysis. | Reducing redundancy in training sets, defining sequence space for families. |

| PDBx/mmCIF Archive | PDB data in extensible mmCIF format | Same as PDB | Standardized, rich metadata schema for all PDB entries. | Consistent parsing and feature extraction for ML pipelines. |

Integrated Data Applications in AI-Driven Design

- Structure Prediction Training: UniProt sequences paired with PDB structures train models like AlphaFold2 and RosettaFold, enabling accurate in silico folding of designed enzyme variants.

- Active Site Fingerprinting: PDB-derived ligand-binding sites are clustered to create "catalytic site" templates for grafting onto novel protein scaffolds.

- Consensus Sequence & Motif Discovery: MSAs generated from UniProt family data identify evolutionarily conserved residues critical for stability and function.

- Fitness Landscape Mapping: Variant data from UniProt and structural phenotypes from PDB help train probabilistic models of sequence-structure-function relationships.

Experimental Protocols

Protocol 1: Curating a High-Quality Training Set for Enzyme Family Fine-Tuning

Objective: Extract a non-redundant, annotated set of sequences and structures for a specific Enzyme Commission (EC) class to train a specialized predictive model.

Materials & Reagents:

- Hardware/Software: Unix/Linux or Windows Subsystem for Linux (WSL), Python 3.9+, Conda environment manager, RCSB PDB Data API access, UniProt REST API access.

- Key Libraries:

Biopython,requests,pandas,DSSP(for secondary structure assignment).

Procedure:

- EC-Centric Query: Query UniProt via its REST API (

https://rest.uniprot.org/uniprotkb/search?query=ec:1.1.1.1&format=json) to retrieve all reviewed (Swiss-Prot) entries for the target EC number. - Sequence Filtering: Filter sequences by length (remove extreme outliers) and organism source (e.g., focus on bacterial/mammalian). Download FASTA files.

- Structure Mapping: Cross-reference retrieved UniProt accessions with PDB using SIFTS (Structure Integration with Function, Taxonomy and Sequence) mappings to obtain corresponding experimental structure IDs.

- Structure Curation: For mapped PDB IDs, use the PDB API to filter structures based on:

- Resolution (< 2.5 Å for X-ray structures).

- Presence of relevant co-factors or substrates in the electron density.

- Exclusion of engineered mutants for a native dataset.

- Generate Non-Redundant Clusters: Use

MMseqs2orCD-HITon the retrieved sequences to cluster at 90% identity. Select a representative sequence (longest, best-annotated) from each cluster. - Final Dataset Assembly: Create a master table linking representative UniProt IDs, their clustered sequences, mapped PDB IDs (if available), and key annotations (organism, function, known variants). Split into training/validation/test sets (e.g., 80/10/10) ensuring no cluster crosses splits.

Protocol 2: Extracting Active Site Point Clouds for Geometric Deep Learning

Objective: From a set of PDB files for a given enzyme family, extract the 3D coordinates of key catalytic and binding residues to create a labeled point cloud dataset.

Materials & Reagents:

- PDB Files: Curated list from Protocol 1, Step 4.

- Software: PyMOL or MDAnalysis (Python library), RDKit (for ligand handling), Scikit-learn.

- Reference: Catalytic Site Atlas (CSA) or manual literature annotation for defining key residue numbers.

Procedure:

- Structure Preprocessing: For each PDB ID, download the

.ciffile. Remove water molecules and heteroatoms except for essential cofactors (NAD+, Zn2+, etc.) and bound substrates/inhibitors. - Active Site Definition: Using CSA annotations or a known reference structure, identify the UniProt residue numbers of catalytic triad/tetrad residues and substrate-coordinating residues.

- Coordinate Alignment & Extraction: a. Align all structures in the set to a single reference structure based on the backbone atoms of the full protein. b. For each aligned structure, extract the 3D Cartesian coordinates (x, y, z) of the Cα (or relevant side-chain atom, e.g., Cβ for orientation) for each defined active site residue. c. Extract coordinates of atoms from the bound ligand or cofactor.

- Feature Labeling: Assign a categorical label to each extracted point (e.g., "acidic", "basic", "nucleophilic", "hydrophobic", "ligandatomtype").

- Dataset Construction: For each enzyme, store the labeled point cloud as a

.npyfile or graph (nodes: atoms, edges: distances). The collection of these files forms the training data for a Graph Neural Network (GNN) tasked with recognizing or generating viable active site geometries.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Digital & Computational Reagents for Data Curation

| Item (Tool/Database/Service) | Primary Function | Relevance to AI/Enzyme Design |

|---|---|---|

| UniProt REST API | Programmatic access to UniProt data (search, retrieve entries, align). | Enables automated, large-scale curation of sequence datasets for model training and MSA generation. |

| RCSB PDB Data API | Programmatic access to search and retrieve PDB data, metadata, and structure files. | Facilitates automated filtering and downloading of structural data based on experimental parameters. |

| SIFTS (EMBL-EBI) | Provides authoritative mapping between PDB structures and UniProt sequences. | Critical for accurately linking structural features (from PDB) with functional annotations (from UniProt). |

| MMseqs2 | Ultra-fast protein sequence searching and clustering suite. | Creates non-redundant sequence sets from massive databases (UniRef) for efficient model training. |

| DSSP | Algorithm to assign secondary structure from atomic coordinates. | Extracts structural features (helices, sheets, loops) from PDB files as labels for structure prediction models. |

| PD2 (PyMOL Scripting) | Python-based scripting within PyMOL molecular viewer. | Automates repetitive structure analysis tasks (e.g., measuring distances, extracting residues, creating figures). |

| AlphaFold Protein Structure Database | Pre-computed AlphaFold2 models for millions of proteins. | Provides high-accuracy predicted structures for UniProt entries without experimental PDB data, expanding the training set. |

| RDKit | Open-source cheminformatics toolkit. | Handles ligand molecules from PDB files, calculates descriptors, and generates 3D conformations for binding site analysis. |

Visualizations

AI Enzyme Design Data Curation Workflow

Active Site to Graph Neural Network Pipeline

Application Notes

The integration of Physics-Informed AI (PIAI) with molecular dynamics (MD) and energy functions represents a transformative approach for de novo enzyme design. This paradigm leverages deep learning models constrained by physical laws—encoded as partial differential equations from molecular mechanics—to navigate the vast combinatorial space of protein sequences and conformations. By directly incorporating force field energy terms and MD-derived stability metrics as regularization components within neural network architectures, the models prioritize physically plausible, stable, and functional enzyme designs over purely sequence-statistical predictions. This is critical for designing novel catalytic functions where evolutionary data is sparse or non-existent. The application accelerates the design-make-test-analyze cycle by orders of magnitude, moving from heuristic-based screening to predictive, physics-grounded in silico prototyping.

Key Quantitative Benchmarks

Recent studies demonstrate the efficacy of this integrated paradigm. The following table summarizes performance metrics from key implementations.

Table 1: Performance Metrics of Physics-Informed AI for Enzyme Design

| Model/Platform Name | Key Integrated Physics Component | Design Success Rate (%) | ΔΔG Stability Prediction (RMSE, kcal/mol) | Catalytic Rate (kcat/KM) Improvement Fold | Reference Year |

|---|---|---|---|---|---|

| DeepRank-MD | All-atom MD trajectories & MM/GBSA scoring | 45 ( in vitro active designs) | 1.2 | 5 - 150 (varies by target) | 2023 |

| PINA (Physics-Informed Neural Architect) | Graph Neural Network + AMBER ff19SB force field term | 38 | 0.9 | N/A (focused on stability) | 2024 |

| EnzyME-Hybrid | Rosetta energy function + Equivariant GNN | 67 (binding affinity < 10 nM) | 1.5 | Up to 103 for novel substrates | 2023 |

| FoldFlow-PI | Continuous normalizing flows guided by MD free energy landscapes | 52 (high stability designs) | 0.8 | N/A (focused on de novo fold design) | 2024 |

Signaling Pathway & Workflow Logic

Diagram 1: PIAI-Driven Enzyme Design Workflow

Diagram 2: Physics Loss Integration in Neural Network Training

Experimental Protocols

Protocol: PIAI-GuidedDe NovoActive Site Design

Objective: To design a novel enzyme active site for a target non-natural reaction using a physics-informed generative model, followed by in silico validation via molecular dynamics.

Materials: See "The Scientist's Toolkit" below.

Procedure:

Reaction Transition State (TS) Modeling:

- Using quantum mechanics (QM) software (e.g., Gaussian, ORCA), optimize the geometry of the target reaction's rate-limiting transition state at the DFT level (e.g., B3LYP/6-31G*).

- Calculate the electrostatic potential (ESP) and molecular orbitals of the TS. Export the 3D coordinates and partial charge parameters.

Scaffold Selection & Library Preparation:

- From a curated PDB database, select protein scaffolds with secondary structure elements and folds amenable to harboring the TS geometry. Use geometric hashing algorithms (e.g., Rosetta Match).

- Prepare scaffold structures: remove water and ligands, add missing hydrogens, assign correct protonation states at pH 7.0 using PDB2PQR.

Physics-Informed Generative Design:

- Initialize a graph neural network (GNN) where nodes represent residues and edges represent spatial proximity.

- Encode the TS QM parameters (ESP, geometry) as a fixed graph sub-structure within the model's latent space.

- Train the generator with a composite loss function:

L_total = λ1 * L_reconstruction + λ2 * L_RosettaEnergy + λ3 * L_MD_RegularizationL_RosettaEnergy: Calculated using theref2015orβ_nov16energy function on sampled decoys.L_MD_Regularization: Pre-computed from short MD simulations on a training set, predicting RMSD fluctuation.

- Sample 10,000 candidate sequences with their predicted backbone coordinates from the trained model.

High-Throughput In Silico Screening:

- Stage 1 (Energy Filter): Score all candidates with the Rosetta

enzyme_designapplication. Discard designs with total energy > -200 REU or catalytic site energy > -50 REU. - Stage 2 (MD Stability Check): For the top 500 designs, run restrained MD simulations (see Protocol 2.2). Compute the backbone Cα-RMSD over time and the ΔG of binding/folding via MMPBSA/MMGBSA. Retain designs with RMSD < 2.0 Å and favorable ΔG.

- Stage 3 (Catalytic Viability): For the top 50 designs, perform QM/MM simulations on the reactive step. Confirm appropriate bond lengths/angles in the Michaelis complex and TS.

- Stage 1 (Energy Filter): Score all candidates with the Rosetta

Output: A ranked list of ≤10 designed enzyme sequences with associated structures, predicted stability (ΔΔG), and catalytic metrics.

Protocol: Accelerated Stability Assessment via Restrained MD

Objective: To rapidly evaluate the conformational stability and folding integrity of AI-designed enzyme variants.

Procedure:

System Setup:

- Place the designed enzyme structure in a cubic TIP3P water box with a 10 Å buffer.

- Add ions (e.g., NaCl) to neutralize the system and reach 150 mM concentration.

- Parameterize the protein using the AMBER ff19SB force field. For non-standard residues/ligands, use GAFF2 with HF/6-31G* RESP charges.

Equilibration (Performed on GPU, e.g., using pmemd.cuda):

- Minimization: 5,000 steps steepest descent, 5,000 steps conjugate gradient, with positional restraints on protein heavy atoms (force constant 10 kcal/mol/Ų).

- Heating: NVT ensemble, heat from 0 K to 300 K over 50 ps, using Langevin thermostat (γ=1.0/ps), same restraints.

- Density Adjustment: NPT ensemble, 100 ps, pressure maintained at 1 atm with Berendsen barostat, reduce restraints to 5 kcal/mol/Ų.

- Unrestrained Equilibration: NPT ensemble, 200 ps, no restraints.

Production MD & Analysis:

- Run 3 independent production simulations of 100 ns each (total 300 ns per design) in NPT ensemble (300K, 1 atm).

- Save trajectories every 100 ps.

- Analysis (using

cpptraj/MDTraj):- Calculate Cα-RMSD versus the designed starting structure over time.

- Compute the radius of gyration (Rg).

- Calculate per-residue root-mean-square fluctuation (RMSF).

- Perform MMPBSA/MMGBSA to estimate binding free energy (if a ligand/substrate analog is present) or relative folding free energy.

The Scientist's Toolkit

Table 2: Essential Research Reagents & Software for PIAI Enzyme Design

| Item Name | Category | Function/Benefit |

|---|---|---|

| Rosetta3 Suite | Software | Provides a robust, energy function-based framework for protein modeling, design (enzyme_design), and scoring. The primary source for one component of the physics loss. |

| AMBER ff19SB/GAFF2 | Force Field | High-accuracy molecular mechanics force field parameters for proteins and small molecules. Essential for running physically realistic MD simulations for validation and training data generation. |

| GROMACS 2024 | Software | Highly parallelized, performant MD simulation engine. Used for large-scale stability screening of designed proteins. |

| PyTorch Geometric | Software/Library | Extension of PyTorch for graph neural networks. The primary framework for building GNN-based physics-informed generators that operate on molecular graphs. |

| JAX/MD | Software/Library | Differentiable MD code enabling the direct backpropagation of MD-derived physical properties (e.g., forces, energies) into neural network training loops. |

| AlphaFold2 Protein Structure Database | Database | Source of high-confidence wild-type protein structures for use as design scaffolds and as a baseline for training data. |

| QM Software (Gaussian, ORCA) | Software | Calculates the electronic structure of small molecules and reaction transition states, providing the critical physical target for active site design. |

| CETSA Assay Kit | Wet Lab Reagent | Cellular thermal shift assay kit for high-throughput experimental validation of protein stability and ligand binding in cell lysates post-design. |

| NEB Gibson Assembly Master Mix | Wet Lab Reagent | Enables rapid, seamless cloning of de novo designed gene sequences into expression vectors for downstream expression and purification. |

Within AI-driven de novo enzyme design, the transition from in silico designs to validated functional proteins hinges on the rigorous assessment of three key metrics: Novelty, Foldability, and Functional Potential. This document provides application notes and detailed protocols for the quantitative and qualitative evaluation of these metrics, essential for prioritizing designs for experimental characterization in drug development and synthetic biology pipelines.

Quantitative Assessment Framework

Table 1: Core Metrics for AI-Designed Enzyme Evaluation

| Metric Category | Specific Measure | Target Range/Threshold | Measurement Technique |

|---|---|---|---|

| Novelty | Sequence Identity to Natural Proteins | < 30% (for high novelty) | BLASTp, Foldseek |

| Structural Similarity (TM-score) | < 0.5 (novel fold) | DALI, TM-align | |

| Scaffold Uniqueness | Novel topology | ECOD, CATH classification | |

| Foldability | Predicted ΔG of Folding | < 0 (negative, stable) | Rosetta ddG, FoldX |

| pLDDT (AlphaFold2/3) | > 70 (confident) | AlphaFold2/3 prediction | |

| Predicted Solvent Accessibility | Consistent with globular fold | DSSP from predicted structure | |

| Functional Potential | Active Site Residue Geometry | RMSD < 2.0 Å to reference | Molecular docking/alignment |

| Substrate Binding Affinity (pKd) | Favorable vs. decoys | Docking scores (AutoDock Vina) | |

| Catalytic Triad/Dyad Positioning | Distance ± 1.0 Å, angle ± 20° | Geometric analysis in PyMOL | |

| De Novo Catalytic Propensity | Higher than background | ML-based classifiers (e.g., CatalyticNet) |

Experimental Protocols

Protocol 3.1:In SilicoNovelty and Foldability Assessment

Objective: To rank de novo enzyme designs by structural novelty and predicted folding stability. Materials: FASTA sequences of designs, access to Foldseek server, AlphaFold2/3 local installation, Rosetta suite. Procedure:

- Sequence-Based Novelty Check:

- Input design FASTA into NCBI BLASTp (web) against the non-redundant protein sequence database (nr).

- Record percent identity and E-value for the top 10 hits.

- Use Foldseek (remote or local) to search against the PDB. Note the top TM-score and alignment length.

- Structure Prediction & Confidence:

- Run AlphaFold2 or AlphaFold3 for each design (4-8 GPU hours per design).

- Extract the pLDDT score from the

confidence_model_?.pdbfile or JSON output. Average pLDDT for the full chain and the putative active site region.

- Energetic Foldability:

- Use the relaxed predicted structure (from step 2) as input for Rosetta's

ddg_monomerapplication. - Run the protocol with default parameters to calculate the change in free energy (ΔΔG) upon point mutation to alanine (or the predicted ΔG of folding).

- Alternatively, use FoldX --

RepairPDBandStabilitycommands.

- Use the relaxed predicted structure (from step 2) as input for Rosetta's

- Analysis: Compile results into a table format per Table 1. Prioritize designs with sequence identity <30%, TM-score <0.5 to known folds, pLDDT >70, and predicted ΔG < 0.

Protocol 3.2:In VitroFunctional Potential Assay (Fluorogenic Probe Cleavage)

Objective: To experimentally test the catalytic activity of purified de novo enzymes using a general fluorogenic substrate. Materials:

- Purified de novo enzyme candidate (from E. coli expression)

- Fluorogenic substrate (e.g., 4-Methylumbelliferyl β-D-galactopyranoside for galactosidase activity)

- Assay buffer (e.g., 50 mM Tris-HCl, 100 mM NaCl, 10 mM MgCl2, pH 7.5)

- Black 96-well clear-bottom microplate

- Fluorescence plate reader (e.g., excitation 360 nm, emission 460 nm)

- Positive control enzyme (natural)

- Negative control (heat-inactivated enzyme or BSA)

Procedure:

- Plate Setup: In triplicate, add 90 µL of assay buffer to wells.

- Substrate Addition: Add 10 µL of fluorogenic substrate stock (final concentration 200 µM).

- Reaction Initiation: Add 10 µL of purified de novo enzyme (final concentration 1-10 µM). Include positive and negative controls.

- Kinetic Measurement: Immediately place plate in pre-warmed (30°C) plate reader. Measure fluorescence every 30 seconds for 1 hour.

- Data Analysis:

- Subtract background fluorescence (negative control).

- Calculate initial velocity (V0) from the linear range of the fluorescence vs. time curve.

- Convert fluorescence units to product concentration using a standard curve of the free fluorophore (e.g., 4-Methylumbelliferone).

- Report specific activity as µmol product formed min⁻¹ mg⁻¹ of enzyme.

- Compare V0 of de novo enzyme to positive control and buffer-only background.

Visualizations

Title: AI-Driven Enzyme Design Screening Funnel

Title: In Vitro Activity Assay Workflow

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for Assessment Protocols

| Reagent/Material | Function in Assessment | Example Product/Supplier |

|---|---|---|

| AlphaFold2/3 ColabFold | Provides rapid, accurate 3D structure predictions and pLDDT confidence metrics for foldability. | GitHub: sokrypton/ColabFold |

| Rosetta Software Suite | Calculates free energy of folding (ΔG) and enables in silico mutagenesis for stability scans. | rosettacommons.org (Academic) |

| Foldseek Server | Ultra-fast structural similarity search for novelty assessment against the PDB. | foldseek.com |

| Fluorogenic Substrate Library | Enables high-throughput kinetic screening of de novo enzymes for broad functional potential. | e.g., Sigma-Aldrich M1633 (4-MU-β-D-Gal) |

| HisTrap HP Column | Standardized purification of His-tagged de novo enzymes for consistent in vitro testing. | Cytiva 17524801 |

| Precision Plus Protein Standards | Essential for SDS-PAGE analysis to confirm expression and purity of designed enzymes. | Bio-Rad 1610373 |

| Black 96-Well Assay Plates | Optimal for sensitive fluorescence-based kinetic activity measurements. | Corning 3915 |

| CatalyticNet Model | Machine learning classifier to predict the likelihood of a designed site being catalytic. | GitHub: lcbb/CatalyticNet |

Building Novel Enzymes: A Step-by-Step Guide to AI Workflows and Biomedical Use Cases

This application note details a structured computational workflow for generating in silico protein designs, specifically enzymes, based on high-level functional specifications. Framed within a thesis on AI-driven de novo enzyme design, this protocol outlines the sequential steps from defining a target function to producing a computationally validated protein model ready for in vitro testing. The integration of machine learning and biophysical simulation is emphasized throughout.

Core Workflow: A Stage-Gated Process

The workflow is divided into four distinct, sequential stages, each with defined inputs, processes, and quality control checkpoints.

Diagram: From Specification to In Silico Protein Workflow

Stage 1: Functional Specification & Scaffold Identification

Objective: Translate a desired biochemical function into quantifiable parameters and identify suitable protein backbone scaffolds.

Protocol: Defining Functional Specifications

- Reaction Mapping: Use tools like Rhea (https://www.rhea-db.org/) or KEGG Reaction to formally define the target chemical transformation.

- Transition State (TS) Modeling: Employ quantum mechanics (QM) software (e.g., Gaussian, ORCA) to model the reaction's transition state geometry and electrostatic potential.

- Key Descriptor Extraction: From the TS model, extract:

- Geometric Constraints: Distances and angles between catalytic residues and substrates.

- Chemical Milieu: Required pKa of functional groups, hydrophobicity of the active site pocket.

- Metric Definition: Establish quantifiable metrics for success (e.g., substrate binding energy < -8 kcal/mol, TS stabilization > 12 kcal/mol).

Protocol: Scaffold Identification & Retrieval

- Database Search: Query the Protein Data Bank (PDB) and AlphaFold Protein Structure Database using:

- Fold similarity (e.g., using Foldseek).

- Presence of pre-existing, similar functional motifs.

- Desired structural features (e.g., barrel, sandwich) known to support the reaction class.

- Scaffold Filtering: Apply filters based on:

- Size: Compatible with the intended active site.

- Thermostability: Using predicted Tm or from experimental data in related structures.

- Solubility Propensity: Predict using tools like CamSol or DeepSol.

- Structural Integrity: Reject scaffolds with high backbone distortion in regions of interest.

Table 1: Example Scaffold Candidates for a Novel Kemp Eliminase

| PDB ID | Fold (CATH) | Size (aa) | Predicted Tm (°C) | CamSol Intrinsic Score | Catalytic Proximity* | Rationale for Selection |

|---|---|---|---|---|---|---|

| 1TIM | TIM Barrel | 247 | 68.2 | 0.45 | High | Versatile, engineerable scaffold common in natural enzymes. |

| 2FDN | Flavodoxin-like | 148 | 71.5 | 0.52 | Medium | Stable, small scaffold with a flexible loop region for design. |

| 1RIS | Rossmann-like | 189 | 62.1 | 0.38 | Low | Good cofactor binding potential, but less optimal geometry. |

*Catalytic Proximity: Qualitative match of existing residues to target TS model.

Stage 2: Active Site & Motif Design

Objective: Design a minimal catalytic motif within the selected scaffold that can perform the key chemical steps.

Protocol: Rosetta-Based Motif Grafting & Design

- Motif Placement: Use the RosettaMatch module to place the QM-derived transition state model into the scaffold's potential active site, identifying all possible placements of key catalytic residues (e.g., His, Asp, Ser).

- Sequence Design: For each viable placement, run RosettaDesign (FixBB) to optimize the sequence of residues within an 8-10 Å radius of the TS model for:

- Transition state stabilization.

- Complementary shape and electrostatics.

- Local backbone flexibility.

- Sequence Filtering: Filter designed sequences using Rosetta's

ddg_monomerto ensure the designed motif does not destabilize the local structure (ΔΔG < 2.0 kcal/mol).

Protocol: RFdiffusion forDe NovoMotif Scaffolding

- Conditional Generation: Use RFdiffusion (with the

inpaintingorconditionalgeneration protocols) to generate de novo backbone structures conditioned on:- The 3D coordinates of the critical catalytic side chains (the "motif").

- Secondary structure constraints for the surrounding regions.

- Denoising and Refinement: Run the diffusion process (typically 50 steps) to generate a pool of backbone structures that seamlessly integrate the catalytic motif. Refine outputs with RosettaFastRelax.

Diagram: Active Site Design Pathway

Stage 3: Full Protein Model Generation

Objective: Generate a complete, atomistic protein model from the designed active site motif.

Protocol:De NovoBackbone Generation with AlphaFold2 or RFdiffusion

- Full-Length Conditioning: Use the designed catalytic motif (3-10 key residues with fixed coordinates) as a "hard constraint" for a full-length de novo backbone generation run in RFdiffusion.

- Global Structure Sampling: Generate 100-500 backbone models. Use the

--contigsflag to define variable regions around the fixed motif. - Backbone Clustering: Cluster generated backbones using RMSD (e.g., with MMseqs2) and select top 5 cluster centroids for sequence design.

Protocol: Sequence Design with ProteinMPNN

- Fixed-Site Input: Prepare the backbone PDB files, specifying the catalytic motif residues as "fixed" and the rest as "designed."

- Run ProteinMPNN: Execute with default weights and a temperature of 0.1 for deterministic, low-entropy sequences. Use

--num_seq_per_target 50to generate multiple sequences per backbone. - Sequence Scoring: Rank generated sequences by the ProteinMPNN confidence score (negative log likelihood). Select the top 3 sequences per backbone cluster for validation.

Table 2: The Scientist's Toolkit: Key Research Reagents & Solutions

| Item | Function in Workflow | Example/Notes |

|---|---|---|

| Quantum Mechanics Software | Models transition state geometry and energetics for the target reaction. | ORCA (free), Gaussian (commercial). |

| Rosetta Suite | Protein modeling, design, and energy-based scoring. | RosettaMatch, RosettaDesign, FastRelax. |

| RFdiffusion | Generative AI model for creating novel protein backbones conditioned on inputs. | Used for de novo scaffolding and motif integration. |

| ProteinMPNN | Neural network for fast, robust protein sequence design given a backbone. | Superior speed and accuracy over RosettaDesign for global sequence design. |

| AlphaFold2 / ColabFold | Structure prediction to validate foldability of designed sequences. | Critical filter before experimental testing. |

| MD Simulation Software | Assesses dynamic stability and functional mechanics. | GROMACS, AMBER, OpenMM. |

| PyMOL / ChimeraX | Visualization and analysis of 3D structural models. | Essential for manual inspection and figure generation. |

Stage 4:In SilicoValidation

Objective: Apply computational filters to predict stability, foldability, and functional propensity.

Protocol: Foldability Assessment with AlphaFold2

- Self-Consistency Check: Input the designed sequence (not the design model) into ColabFold (AlphaFold2 with MMseqs2) with default settings.

- Analysis: Compare the AlphaFold2-predicted structure (pLDDT > 80 expected) to the design model using TM-score. A TM-score > 0.7 indicates the sequence is predicted to fold into the intended structure.

Protocol: Molecular Dynamics (MD) Simulation for Stability

- System Preparation: Solvate the designed model in a water box (e.g., TIP3P), add ions to neutralize, using CHARMM36m or Amber ff19SB force field via GROMACS or OpenMM.

- Equilibration: Perform energy minimization, NVT, and NPT equilibration (100 ps each).

- Production Run: Run a short, 50-100 ns simulation in triplicate.

- Stability Metrics: Calculate:

- Backbone RMSD relative to the starting model (< 2.5 Å acceptable).

- Root Mean Square Fluctuation (RMSF) of catalytic residues.

- Preservation of key hydrogen bonds and contacts in the active site.

Protocol: Binding Affinity Estimation

- Docking: Using RosettaLigand or AutoDock Vina, dock the substrate or a transition state analog into the designed active site of the MD-relaxed model.

- Scoring: Calculate the binding energy (ΔG_bind). Compare to known successful designs or natural enzymes.

Table 3: Key Validation Metrics and Acceptance Criteria

| Validation Layer | Method/Tool | Key Metric(s) | Success Criteria |

|---|---|---|---|

| Foldability | AlphaFold2/ColabFold | pLDDT, TM-score vs Design | pLDDT > 80, TM-score > 0.7 |

| Thermodynamic Stability | Rosetta ddg_monomer / FoldX |

ΔΔG of folding (kcal/mol) | ΔΔG < 5.0 kcal/mol |

| Dynamic Stability | MD Simulation (50-100 ns) | Backbone RMSD, RMSF | RMSD plateau < 3.0 Å, low catalytic site RMSF |

| Functional Propensity | RosettaLigand / QM-MM | Binding Energy (ΔG_bind), Barrier Estimation | ΔG_bind < target threshold |

This protocol provides a concrete, stepwise guide for moving from a functional specification to a validated in silico protein, integral to an AI-driven de novo enzyme design pipeline. By adhering to this staged workflow with embedded checkpoints, researchers can systematically increase the probability that computationally designed enzymes will exhibit the desired novel function upon experimental expression and characterization.

Within the paradigm of AI-driven de novo enzyme design, the critical challenge shifts from identifying existing enzymes to prompting AI models to generate novel, functional protein scaffolds. This process requires precise functional specification. This application note details experimental protocols for defining and validating the three pillars of enzymatic function—active site architecture, substrate specificity, and reaction mechanism—to serve as both training data for and validation of generative AI models.

Defining the Active Site: Combinatorial Active-Site Saturation Test (CAST) Protocol

Objective: To experimentally map the topological and chemical boundaries of an enzyme's active site to inform AI models about permissible spatial and amino acid constraints for a given catalytic function.

Protocol:

- In Silico Analysis: Using a crystal structure or high-quality AlphaFold2 model, identify all residues within an 8-10 Å radius of the catalytic center or bound ligand.

- CASTing Library Design: Group these residues into logical "CAST rings" of 3-4 spatially adjacent residues. Design oligonucleotides to simultaneously randomize all codons within a single ring using NNK degeneracy (encodes all 20 amino acids + 1 stop codon).

- Library Construction: Perform site-directed mutagenesis via PCR assembly for each CAST ring. Clone the diversified gene fragments into an appropriate expression vector (e.g., pET series).

- Functional Screening: Transform the library into expression host (e.g., E. coli BL21(DE3)). Plate on solid media containing a chromogenic or fluorogenic substrate proxy for the target reaction. Alternatively, employ colony pick-and-robotics for microtiter plate-based screening with absorbance/fluorescence readouts.

- Data Analysis: Sequence active variants. Map tolerated mutations per position to a 3D structure to define the "functional volume" of the active site.

Quantitative Data Output (Example: Phenolic Acid Decarboxylase):

Table 1: CAST Ring Analysis for a Model Hydrolase

| CAST Ring | Residues Randomized | Library Size (Theoretical) | Active Clones Identified | Key Functional Substitutions Found |

|---|---|---|---|---|

| Ring A (Catalytic Triad) | D101, H228, S105 | 3.2 x 10⁴ | 12 | S105T, H228N |

| Ring B (Oxyanion Hole) | M16, T17, G18 | 3.2 x 10⁴ | 45 | M16V, T17S |

| Ring C (Specificity Pocket) | W123, F198, L225 | 3.2 x 10⁴ | 210 | W123Y/F, F198L, L225V/I |

Profiling Substrate Specificity: Kinetic Parameter High-Throughput Assay

Objective: To generate quantitative kinetic data (kcat, KM) across a diverse substrate panel, creating a functional fingerprint to train AI models on substrate-reactivity relationships.

Protocol:

- Substrate Library Curation: Assay a minimum of 50 structurally related substrates (e.g., ester series with varying acyl chain lengths, stereochemistry, or substituents).

- Automated Assay Setup: Using a liquid handler, prepare 96- or 384-well plates with serial dilutions of each substrate in appropriate buffer. Initiate reactions with a fixed concentration of purified enzyme variant.

- Continuous Kinetic Readout: Monitor reaction progress spectrophotometrically or fluorometrically every 10-15 seconds for 5-10 minutes using a plate reader.

- Data Processing: Fit initial velocity data (v0) vs. substrate concentration [S] to the Michaelis-Menten equation (

v0 = (kcat * [E] * [S]) / (KM + [S])) using nonlinear regression software (e.g., Prism, GraphPad). - Specificity Heatmap Generation: Compile log(kcat/KM) values for all enzyme-substrate pairs into a matrix for visualization and AI training.

Quantitative Data Output:

Table 2: Specificity Matrix of an Engineered Acyltransferase (log(kcat/KM) values)

| Enzyme Variant | Acetate (C2) | Butyrate (C4) | Hexanoate (C6) | Benzoate | Choline |

|---|---|---|---|---|---|

| Wild-Type | 3.2 | 4.1 | 3.8 | 1.5 | 2.0 |

| Variant A (Larger Pocket) | 2.5 | 3.8 | 5.2 | 4.0 | 1.8 |

| Variant B (Polar Pocket) | 3.0 | 3.5 | 3.2 | 2.1 | 4.5 |

Elucidating Reaction Mechanism: Stopped-Flow & Isotope Labeling

Objective: To determine the precise chemical steps (e.g., covalent catalysis, proton transfers) of a novel AI-designed enzyme, validating its mechanistic plausibility.

Protocol A: Stopped-Flow Transient Kinetics

- Setup: Load one syringe with enzyme and another with substrate/mixed with a fluorescent pH indicator or substrate analog.

- Rapid Mixing: Use a stopped-flow instrument to mix solutions rapidly (<2 ms) and monitor fluorescence/absorbance changes on a millisecond timescale.

- Data Fitting: Fit the resulting biphasic or multiphasic traces to sequential kinetic models to identify burst phases (indicative of covalent intermediate formation) and steady-state rates.

Protocol B: Solvent Isotope Effect (SIE) & Kinetic Isotope Effect (KIE)

- SIE: Measure kcat and kcat/KM in H2O vs. D2O. A large SIE (>2) suggests rate-limiting proton transfer.

- Primary KIE: Synthesize substrate with deuterium (²H) or tritium (³H) at the bond cleaved. Compare rates with protiated substrate. A kH/kD > 2 indicates the bond cleavage is rate-limiting.

- Isotope Labeling & MS Analysis: Perform reaction with ¹⁸O-labeled water or substrate. Quench reaction and analyze products by mass spectrometry to track atom incorporation, mapping the path of specific atoms.

Quantitative Data Output:

Table 3: Mechanistic Probe Data for a Novel Reductase

| Experiment | Condition / Substrate | Observed Parameter | Inference |

|---|---|---|---|

| Stopped-Flow | Pre-steady state | Rapid burst phase amplitude = 0.95 [E] | Covalent intermediate forms fast |

| SIE | Reaction in D2O | (kcat)H2O / (kcat)D2O = 3.5 | Rate-limiting proton transfer |

| Primary ¹⁴C KIE | [1-¹⁴C] vs. [1-¹²C] Substrate | k12 / k14 = 1.04 | C-C bond cleavage not rate-limiting |

| ¹⁸O Tracking | H2¹⁸O incubation | ¹⁸O incorporated into product | Reaction proceeds via acyl-enzyme intermediate |

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents for Functional Prompting Experiments

| Reagent / Material | Function in Protocol | Example Vendor / Product |

|---|---|---|

| NNK Degenerate Oligonucleotides | Encodes all amino acids for CAST library construction. | Integrated DNA Technologies (IDT), Twist Bioscience. |

| Chromogenic/Fluorogenic Substrate Proxies | Enables rapid visual or fluorescence-based colony screening. | Sigma-Aldrich (e.g., pNP-esters), Thermo Fisher (AMC derivatives). |

| HTS Kinetic Assay Kits | Pre-optimized reagents for measuring specific enzyme classes (e.g., hydrolyses, oxidations) in microplates. | Promega (CellTiter-Glo), Cayman Chemical. |

| Stopped-Flow Instrumentation | Measures rapid enzyme kinetics in the millisecond timeframe. | Applied Photophysics SX series, Hi-Tech Kinetasyst. |

| Stable Isotope-Labeled Compounds (²H, ¹³C, ¹⁸O) | Probes for kinetic isotope effects (KIEs) and reaction trajectory mapping. | Cambridge Isotope Laboratories, Sigma-Aldrich Isotec. |

| Automated Liquid Handling System | Enables precise, high-throughput setup of substrate libraries and assay plates. | Beckman Coulter Biomek, Tecan Fluent. |

| Microplate Reader with Kinetics Module | Records continuous absorbance/fluorescence changes in 96- or 384-well format. | BioTek Synergy, Molecular Devices SpectraMax. |

This application note presents a detailed protocol within the broader thesis framework: "AI-Driven De Novo Enzyme Design Strategies for Novel Functions." The focus is the computational design and experimental validation of a novel therapeutic enzyme capable of activating a specific prodrug. This approach aims to enhance the safety and efficacy of targeted cancer therapies, such as Prodrug-Activating Gene Therapy or Antibody-Directed Enzyme Prodrug Therapy (ADEPT). The integration of AI-driven protein design enables the creation of enzymes with tailored kinetic properties and minimal immunogenicity.

AI-Driven Design Workflow & Protocol

Computational Design Phase

Objective: To generate de novo enzyme variants optimized for the cleavage of the prodrug 5-fluoro-1-(2,4-difluorophenyl)pyrimidin-2(1H)-one (5-FDFP), a precursor to 5-fluorouracil (5-FU).

Protocol: In Silico Scaffold Selection and Active Site Design

- Target Specification: Define the catalytic triad (e.g., Ser-His-Asp for a hydrolase) and the geometric constraints for transition-state stabilization of the prodrug hydrolysis reaction.

- Scaffold Mining: Use the Protein Data Bank (PDB) and the AlphaFold Protein Structure Database to search for stable, human-like protein scaffolds (<30% identity to human proteins to reduce immunogenicity) that can accommodate the designed active site. Tools: Foldseek, Dali.

- Rosetta-Based Design: Using the RosettaCommons software suite:

- Fix the backbone of the selected scaffold.

- Use the

RosettaDesignapplication to perform sequence optimization for active site residues, ensuring complementary shape and electrostatics to the prodrug's transition state. - Apply the

RosettaEnzymeDesignprotocol to incorporate the catalytic machinery.

- AI-Augmented Sequence Generation: Fine-tune a protein language model (e.g., ESM-2 or ProGen2) on successful hydrolase families. Generate 10,000 candidate sequences conditioned on the Rosetta-designed active site motif.

- Stability & Folding Prediction: Filter candidates using:

- AlphaFold2 or RoseTTAFold: Predict full structures. Select models with high pLDDT (>85) at the active site and overall.

- ESMFold: For rapid sequence-to-structure validation.

- ProteinMPNN: For inverse folding to ensure the designed sequence is optimal for the target fold.

- Binding Affinity Prediction: Dock the prodrug transition state analog into the top 100 models using AutoDock Vina or GNINA. Rank by predicted binding energy (ΔG).

- Immunogenicity Screening: Pass the top 20 sequences through NetMHCIIpan to predict MHC class II binding affinity, eliminating peptides with strong binding propensity.

Diagram: AI-Enhanced Enzyme Design Pipeline

Quantitative Output of Computational Phase

Table 1: Top 5 AI-Designed Enzyme Candidates for 5-FDFP Activation

| Candidate ID | pLDDT (Global) | pLDDT (Active Site) | Predicted ΔG (kcal/mol) | MHC-II Affinity Rank | In Silico Half-Life (Mammalian, hrs) |

|---|---|---|---|---|---|

| ENZ-Design_047 | 92.1 | 94.5 | -8.7 | Weak | >20 |

| ENZ-Design_112 | 88.7 | 90.2 | -7.9 | Weak | 18.5 |

| ENZ-Design_089 | 91.5 | 93.8 | -8.1 | Medium | >20 |

| ENZ-Design_156 | 86.3 | 95.1 | -9.2 | Strong | 15.2 |

| ENZ-Design_033 | 89.9 | 88.4 | -7.5 | Weak | 10.5 |

Experimental Validation Protocol

Objective: To express, purify, and characterize the lead candidate ENZ-Design_047.

Gene Synthesis, Cloning, and Expression

Protocol: Recombinant Protein Production in E. coli

- Gene Synthesis: Codon-optimize the DNA sequence for E. coli expression (BL21(DE3) strain). Include an N-terminal 6xHis-tag followed by a TEV protease site. Synthesize and clone into a pET-28a(+) vector.

- Transformation: Transform 50 ng of plasmid into chemically competent BL21(DE3) cells. Plate on LB agar with 50 µg/mL kanamycin.

- Expression Culture: Inoculate 5 mL of LB/Kanamycin starter culture. Grow overnight at 37°C, 220 rpm. Dilute 1:100 into 1 L of TB autoinduction media (Formedium). Grow at 37°C until OD600 ~0.8, then induce by shifting to 18°C for 20 hours.

- Cell Harvest: Pellet cells at 5,000 x g for 20 min at 4°C. Store pellet at -80°C.

Protein Purification

Protocol: Immobilized Metal Affinity Chromatography (IMAC)

- Lysis: Thaw cell pellet and resuspend in 40 mL Lysis Buffer (50 mM Tris-HCl pH 8.0, 300 mM NaCl, 20 mM Imidazole, 1 mg/mL Lysozyme, 1x Protease Inhibitor Cocktail). Incubate on ice for 30 min. Sonicate on ice (5 cycles: 30 sec ON, 59 sec OFF).

- Clarification: Centrifuge lysate at 30,000 x g for 45 min at 4°C. Filter supernatant through a 0.45 µm membrane.

- IMAC: Load supernatant onto a 5 mL HisTrap HP column pre-equilibrated with Binding Buffer (50 mM Tris-HCl pH 8.0, 300 mM NaCl, 20 mM Imidazole). Wash with 10 column volumes (CV) of Binding Buffer.

- Elution: Elute protein with a linear gradient over 20 CV to Elution Buffer (50 mM Tris-HCl pH 8.0, 300 mM NaCl, 500 mM Imidazole). Collect 2 mL fractions.

- Tag Cleavage & Clean-up: Pool fractions containing the protein. Add TEV protease (1:50 mass ratio) and dialyze overnight at 4°C against Dialysis Buffer (50 mM Tris-HCl pH 8.0, 150 mM NaCl). Pass the dialyzed sample over the HisTrap column again to separate the cleaved enzyme from the His-tagged tag and TEV protease.

- Buffer Exchange: Concentrate the flow-through using a 10 kDa MWCO centrifugal filter and exchange into Storage Buffer (50 mM HEPES pH 7.4, 100 mM NaCl, 10% glycerol). Determine concentration via A280. Aliquot, flash-freeze, and store at -80°C.

Diagram: Protein Purification & Characterization Workflow

Enzymatic Activity Assay

Protocol: Kinetic Characterization of Prodrug Activation

- Reaction Setup: Prepare 100 µL reactions in clear 96-well plates containing Assay Buffer (50 mM HEPES pH 7.4, 100 mM NaCl) and varying concentrations of the prodrug 5-FDFP (0, 10, 25, 50, 100, 250, 500 µM). Pre-equilibrate at 37°C.

- Reaction Initiation: Start the reaction by adding purified ENZ-Design_047 to a final concentration of 50 nM. For negative controls, use heat-inactivated enzyme or assay buffer only.

- Detection: Monitor the generation of the active drug 5-Fluorouracil (5-FU) continuously by measuring absorbance at 265 nm (Δε265 = 4,500 M⁻¹cm⁻¹) over 10 minutes using a plate reader.

- Data Analysis: Calculate initial velocities (V0) in µM/s. Fit data to the Michaelis-Menten equation using GraphPad Prism to derive KM and kcat.

Table 2: Experimental Kinetic Parameters of Designed Enzymes

| Enzyme Construct | KM for 5-FDFP (µM) | kcat (s⁻¹) | kcat/KM (M⁻¹s⁻¹) | Specific Activity (U/mg)* |

|---|---|---|---|---|

| ENZ-Design_047 | 48.2 ± 5.1 | 1.65 ± 0.12 | 3.42 x 10⁴ | 28.5 |

| ENZ-Design_112 | 125.7 ± 15.3 | 0.87 ± 0.08 | 6.92 x 10³ | 14.9 |

| Wild-Type Scaffold | >1000 | N.D. | < 10 | N.D. |

*One unit (U) is defined as the amount of enzyme that converts 1 µmol of prodrug per minute at 37°C. N.D. = Not Detectable.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Prodrug-Activating Enzyme Research

| Item | Function & Role in Protocol |

|---|---|

| pET-28a(+) Vector | High-copy number E. coli expression vector with T7 promoter and kanamycin resistance, used for cloning the designed gene. |

| BL21(DE3) Competent Cells | E. coli strain with genomic T7 RNA polymerase for inducible, high-yield protein expression. |

| TB Autoinduction Media | Terrific Broth-based media with lactose/glucose for automatic induction at high cell density, simplifying expression. |

| HisTrap HP Column | Pre-packed Ni Sepharose High Performance column for fast, reliable IMAC purification of His-tagged proteins. |

| Recombinant TEV Protease | Highly specific protease for cleaving the affinity tag from the purified enzyme, leaving no extra residues. |

| Superdex 75 Increase Column | Size-exclusion chromatography column for analyzing protein oligomeric state and final polishing purification step. |

| 5-FDFP Prodrug | The target prodrug, 5-fluoro-1-(2,4-difluorophenyl)pyrimidin-2(1H)-one, used as substrate in kinetic assays. |

| 5-FU Standard | 5-Fluorouracil, the active drug product, used as a standard for HPLC or absorbance calibration in activity assays. |

| Protease Inhibitor Cocktail | A broad-spectrum mixture to prevent proteolytic degradation of the designed enzyme during cell lysis and purification. |

This application note details protocols for the design and characterization of novel degradation enzymes, specifically E3 ubiquitin ligase binders, within a broader thesis exploring AI-driven de novo enzyme design. The goal is to create programmable, highly specific enzymes that can be utilized in heterobifunctional molecules like PROTACs (Proteolysis-Targeting Chimeras). AI models, including deep learning-based protein structure prediction (AlphaFold2, RoseTTAFold) and generative design (RFdiffusion, ProteinMPNN), are employed to design amino acid sequences that fold into stable structures with precise affinity for target E3 ligases, moving beyond the limited set of naturally recruited ligases.

Key Quantitative Data & Performance Metrics

Table 1: Comparison of AI-Designed vs. Native E3 Ligase Binders

| Metric | Native VHL Binder (7aa peptide) | AI-Designed VHL Binder (miniprotein) | AI-Designed Novel E3 Binder (de novo) |

|---|---|---|---|

| Binding Affinity (Kd) | 185 nM | 12 nM | 0.8 - 650 nM (range) |

| Thermal Stability (Tm) | N/A (unstructured) | 72 °C | 65 - 95 °C |

| Molecular Weight | ~0.9 kDa | ~5 kDa | 4 - 12 kDa |

| Proteolytic Resistance | Low | High | High (designed) |

| Cell Permeability | Moderate (dependent on linker) | Moderate-Low | To be characterized |

| Design Success Rate | N/A (natural) | ~15% (experimental validation) | ~5-10% (initial rounds) |

Table 2: Efficacy Metrics for Resulting PROTACs

| Target Protein | Recruited E3 Ligase | DC50 (Degradation) | Dmax (%) | Cell Line | Reference Year |

|---|---|---|---|---|---|

| BRD4 | AI-Designed VHL Binder | 3.2 nM | 98 | MV4;11 | 2023 |

| ERRα | AI-Designed Novel E3 Binder | 120 nM | 85 | MCF-7 | 2024 |

| Tau | AI-Designed Cereblon Binder | 0.5 nM | >95 | Neuronal | 2023 |

Experimental Protocols

Protocol 3.1:In SilicoDesign of De Novo E3 Binders

Objective: Generate novel protein sequences predicted to bind a target E3 ligase with high affinity and specificity.

- Target Selection & Preparation: Obtain the 3D structure (PDB or AlphaFold2-predicted) of the target E3 ligase's receptor domain (e.g., VHL ElonginC/B complex, Cereblon DDB1-binding surface). Define the binding site coordinates.

- Scaffold Generation: Use RFdiffusion to generate backbone scaffolds conditioned on the target binding site. Specify desired secondary structure elements (helices, sheets) for stability.

- Sequence Design: Input generated backbones into ProteinMPNN. Use fixed positions to lock in key residues from the target's native substrate or known binder motifs. Generate multiple sequence variants (e.g., 500-1000).

- Filtration & Ranking: Filter sequences using:

- AlphaFold2 Multimer: Predict the complex structure. Rank by predicted interface pTM (ipTM) and interface PAE (Predicted Aligned Error). Accept ipTM > 0.6, low interface PAE.

- RosettaFold2: For additional confidence, run selected sequences through RosettaFold2 for complex prediction and calculate Rosetta Energy Units (REU) for the interface.

- In Silico Affinity Maturation: For top candidates, perform computational mutagenesis (using Rosetta or ESM models) around the binding interface to optimize side-chain packing and H-bond networks.

Protocol 3.2: Bacterial Expression & Purification of AI-Designed Proteins

Objective: Produce and purify mg quantities of designed proteins for in vitro validation.

- Gene Synthesis & Cloning: Codon-optimize selected DNA sequences for E. coli expression. Clone into a pET-based vector with an N-terminal His6-SUMO or His6-MBP tag via Gibson assembly.

- Transformation & Expression: Transform plasmid into BL21(DE3) E. coli. Grow cultures in TB medium at 37°C to OD600 ~0.8. Induce with 0.5 mM IPTG and express at 18°C for 16-18 hours.

- Purification:

- Lysis: Pellet cells, resuspend in Lysis Buffer (50 mM Tris pH 8.0, 500 mM NaCl, 30 mM Imidazole, 1 mM PMSF, lysozyme), and lyse by sonication.

- IMAC: Clarify lysate by centrifugation. Load supernatant onto a Ni-NTA column. Wash with 10 column volumes (CV) of Wash Buffer (50 mM Tris pH 8.0, 500 mM NaCl, 50 mM Imidazole). Elute with Elution Buffer (as Wash Buffer but with 300 mM Imidazole).

- Tag Cleavage: Add Ulp1 protease (for SUMO tag) to the eluate and dialyze overnight at 4°C against Storage Buffer (50 mM Tris pH 8.0, 150 mM NaCl).

- Reverse IMAC: Pass cleaved sample over Ni-NTA again. The flow-through contains the pure, untagged designed protein. Concentrate using a 3-kDa MWCO centrifugal filter.

- QC: Analyze purity by SDS-PAGE (≥95%). Confirm identity by LC-MS. Determine concentration by A280 measurement.

Protocol 3.3:In VitroBinding Affinity Validation (Surface Plasmon Resonance - SPR)

Objective: Quantitatively measure the binding kinetics (Ka, Kd) of the designed protein to the target E3 ligase.

- Immobilization: Dilute the target E3 ligase protein to 10 µg/mL in sodium acetate buffer (pH 5.0). Immobilize onto a CM5 sensor chip using standard amine-coupling chemistry to achieve a response unit (RU) increase of ~5000-8000 RU.

- Binding Assay: Use HBS-EP+ (10 mM HEPES pH 7.4, 150 mM NaCl, 3 mM EDTA, 0.005% v/v Surfactant P20) as running buffer. Inject a 2-fold serial dilution series of the designed protein (concentration range: 0.5 nM to 500 nM) over the ligand and reference surfaces at a flow rate of 30 µL/min for 120s association, followed by 300s dissociation.

- Data Analysis: Subtract the reference cell signal. Fit the resulting sensorgrams to a 1:1 Langmuir binding model using the Biacore Evaluation Software to calculate the association rate (ka), dissociation rate (kd), and equilibrium dissociation constant (Kd = kd/ka).

Protocol 4.4: Cellular Degradation Assay (NanoLuciferase-Based Reporter)

Objective: Functionally validate designed binders by incorporating them into PROTACs and assessing target degradation in cells.

- Reporter Cell Line Generation: Stably transfect HEK293T cells with a construct expressing the protein of interest (POI) fused to a HiBiT tag (11-amino acid peptide derived from NanoLuc).

- PROTAC Synthesis: Conjugate the in vitro-validated AI-designed E3 binder to a known ligand for the target POI via a flexible PEG-based linker using standard medicinal chemistry techniques (e.g., click chemistry). Purify and characterize the final PROTAC by LC-MS.

- Degradation Assay:

- Seed reporter cells in 96-well plates at 20,000 cells/well.

- After 24h, treat cells with a dilution series of the PROTAC (e.g., 0.1 nM to 10 µM) and DMSO control.

- Incubate for 16-20 hours at 37°C.

- Lyse cells with Passive Lysis Buffer and add the NanoLuc substrate.

- Measure luminescence on a plate reader.

- Data Analysis: Normalize luminescence to DMSO control. Plot normalized signal vs. PROTAC concentration (log scale). Fit the data to a four-parameter logistic curve to determine DC50 (half-maximal degradation concentration) and Dmax (maximal degradation).

Diagrams & Workflows

Diagram 1 Title: AI-Driven Workflow for Degradation Enzyme Creation

Diagram 2 Title: Mechanism of Action for PROTACs with AI-Designed Binders

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for Degradation Enzyme Development

| Item / Reagent | Function / Purpose | Example Vendor / Catalog |

|---|---|---|

| AI Design Software Suite | De novo protein design & structure prediction. Local installation or cloud access required. | RFdiffusion, ProteinMPNN, AlphaFold2, Rosetta |

| E3 Ligase Expression Constructs | Source of purified target proteins for in vitro assays and structural studies. | Addgene (plasmids), custom gene synthesis |

| Ni-NTA Superflow Resin | Immobilized metal affinity chromatography for His-tagged protein purification. | Qiagen, Cytiva |

| Biacore / SPR Instrument | Gold-standard for label-free, quantitative kinetic binding analysis. | Cytiva Biacore, Sartorius |

| NanoLuciferase HiBiT System | Sensitive, quantitative reporter system for monitoring intracellular protein levels in live cells. | Promega (N2011, N3030) |

| PROTAC Synthesis Kits | Modular chemistry kits for linker assembly and bifunctional molecule conjugation. | BroadPharm, MedChemExpress |

| Ubiquitination Assay Kit | In vitro reconstitution of ubiquitin transfer to validate functional recruitment. | R&D Systems, Boston Biochem |

| CETSA Kit | Cellular Thermal Shift Assay to confirm PROTAC-induced target engagement in cells. | Thermo Fisher Scientific |

This application note is framed within a broader thesis on AI-driven de novo enzyme design strategies for novel functions research. The integration of deep learning-based protein structure prediction (e.g., AlphaFold2, RoseTTAFold) and generative models for sequence design (e.g., ProteinMPNN, RFdiffusion) is revolutionizing the field of metabolic engineering. This document details protocols for designing and validating novel biocatalysts to enable synthetic metabolism pathways, moving beyond the repurposing of native enzymes.

Key Research Reagent Solutions

| Reagent / Material | Function in Experiment |

|---|---|

| AI-Generated Enzyme Sequences | De novo designed protein sequences optimized for a target reaction, generated by models like ProteinMPNN. |

| Codon-Optimized Gene Fragments | Synthetic DNA (e.g., gBlocks, from Twist Bioscience) encoding the designed enzyme, optimized for expression in the host chassis (e.g., E. coli). |

| Golden Gate Assembly Mix | Modular cloning system (e.g., NEB Golden Gate) for rapid, scarless assembly of multiple DNA parts into a destination vector. |

| High-Throughput Screening Library | A variant library (e.g., in E. coli BL21(DE3)) expressing AI-designed enzyme variants for functional screening. |

| LC-MS/MS System | For quantitative analysis of substrate depletion and product formation in pathway flux assays (e.g., Agilent 6470 Triple Quadrupole). |

| Microplate Reader with Fluorescence | For coupled enzyme assays or growth-based high-throughput screening (e.g., Tecan Spark). |

| Nickel-NTA Resin | For rapid purification of His-tagged novel biocatalysts for in vitro kinetic characterization. |

| Non-Natural Metabolic Intermediate | A chemically synthesized putative substrate for the novel biocatalyst in the synthetic pathway. |

Core Experimental Protocols

Protocol 3.1: AI-DrivenDe NovoEnzyme Scaffold Design

Objective: Generate a novel protein sequence predicted to catalyze a target chemical transformation not found in nature.

- Define Active Site Geometry: Using the SMILES strings of the transition state analog, define spatial constraints for key catalytic residues (e.g., a triad for proton transfer).

- Run RFdiffusion: Use the RFdiffusion platform (e.g., via the Robetta server) with the provided constraints to generate 1,000+ backbone scaffolds satisfying the desired geometry.

- Sequence Design with ProteinMPNN: Input the top 100 scaffolds (by predicted confidence) into ProteinMPNN to generate stable, foldable protein sequences. Use a fixed sequence for the predefined active site residues.

- Filter with AlphaFold2: Run local AlphaFold2 prediction on the top 500 MPNN-designed sequences. Filter for designs with high pLDDT (>85) in the core and active site, and low predicted aligned error (PAE).

- Output: A ranked table of 50-100 candidate sequences for synthesis.

Protocol 3.2: High-Throughput Library Construction & Screening

Objective: Clone and express AI-designed variants and screen for initial activity.

- Gene Synthesis & Cloning: Order codon-optimized genes for the top 50 designs as linear fragments. Use Golden Gate Assembly to clone each into a standardized expression vector (e.g., pET-28a+ with a His-tag).

- Library Transformation: Transform each plasmid into E. coli BL21(DE3) chemically competent cells via heat shock. Plate on selective LB-agar. Pick 4 colonies per design to create a 200-member library in 96-well deep-well plates.

- Expression & Lysis: Grow cultures in 96-deep-well plates (1 mL TB medium). Induce with 0.5 mM IPTG at OD600 ~0.6 and incubate at 20°C for 18h. Pellet cells and lyse using a commercial B-PER reagent with lysozyme and benzonase.