Navigating Unstable Controls in IC50 Assays: A Comprehensive Guide for Accurate Drug Potency Estimation

This article addresses the critical challenge of unstable positive and negative controls in IC50 estimation assays, a common issue that can compromise data reliability in drug discovery and development.

Navigating Unstable Controls in IC50 Assays: A Comprehensive Guide for Accurate Drug Potency Estimation

Abstract

This article addresses the critical challenge of unstable positive and negative controls in IC50 estimation assays, a common issue that can compromise data reliability in drug discovery and development. Aimed at researchers and scientists, it provides a foundational understanding of control instability, explores advanced methodological adaptations, offers practical troubleshooting strategies, and compares validation approaches to ensure robust and reproducible potency measurements despite experimental variability.

Understanding the Core Problem: Why Unstable Controls Undermine IC50 Data Integrity

Welcome to the Technical Support Center for IC50 Estimation Research. This resource is designed to assist researchers and scientists navigating the challenges of dose-response analysis in the presence of unstable control signals—a core focus of modern pharmacological assay development.

Troubleshooting Guides & FAQs

Q1: Our negative control (DMSO/buffer) baseline optical density (OD) or fluorescence intensity (RFU) shows a consistent upward drift over the course of a 6-month project. How does this impact IC50 estimation, and how can we correct for it?

A: A drifting baseline directly inflates the calculated % inhibition, leading to an overestimation of compound potency (falsely lower IC50). This is a classic "drifting baseline" instability.

- Immediate Action: Re-process existing data using a per-plate normalization. Do not use a historical baseline average.

- Protocol for Correction:

- For each assay plate, calculate the average signal of the n negative control wells (µneg).

- Calculate the average signal of the n positive control (e.g., reference inhibitor) wells (µpos).

- Normalize each well's raw signal (X) using the formula: % Inhibition = [(µneg - X) / (µneg - µ_pos)] * 100

- Re-fit the dose-response curves with the normalized data.

- Preventive Solution: Implement a quarterly reagent requalification protocol. Test new lots of assay kits, serum, or critical buffers against the current lot in a side-by-side experiment. Accept only if the derived IC50 for a reference compound shifts by < 0.3 log units.

Q2: The maximal response (Top) of our assay, defined by a saturating concentration of a control inhibitor, varies erratically from 70% to 95% inhibition. Is our IC50 data still reliable?

A: Erratic maximal responses ("Top instability") severely compromise reliability. A shallow or variable top plateau introduces high uncertainty in the curve fitting, making the IC50 highly sensitive to minor data fluctuations.

- Troubleshooting Steps:

- Check Target Engagement: Confirm the control inhibitor is still fully potent and its stock solution is stable (e.g., by LC-MS).

- Check Assay Dynamics: If using a kinetic read, ensure the reaction has reached endpoint before measurement. Run a time-course for the positive control.

- Check Detection System: Ensure the signal from the zero-activity state (e.g., lysed cells, enzyme-free well) is consistent. A drifting "background floor" will compress the dynamic range.

- Protocol for Quality Control: Introduce a "Top Plateau Acceptability Range".

- Fit your control inhibitor curve. The fitted Top must be within 85% ± 5% inhibition.

- If outside this range, the entire plate is flagged for repetition.

- Document the frequency of plate failures—an increasing rate indicates a systemic reagent or protocol issue.

Q3: When fitting a 4-parameter logistic (4PL) model, should we fix the Bottom or Top parameters when controls are unstable?

A: The decision is critical and data-dependent. Fixing parameters can reduce estimate variability but introduces bias if done incorrectly.

- Guidance Table:

| Control Instability Type | Recommended Constraint | Rationale |

|---|---|---|

| Stable Baseline, Erratic Top | Fix Bottom = 0% Inhibition | Assumes the negative control is consistently defining the uninhibited state. Allows the model to focus on fitting the variable maximal response. |

| Drifting Baseline, Stable Top | Fix Top = 100% Inhibition | Assumes the positive control consistently defines full inhibition. Normalizes the baseline drift. |

| Both Baseline & Top Unstable | Do not fix parameters. Use a per-plate control normalization (see Q1) before fitting. | Fixing either parameter will compound the error from the other unstable control. Normalization external to the fit is safer. |

Q4: What statistical metrics should we report to acknowledge control instability in our publication's Methods section?

A: Transparency is key. Report the following for each experiment:

- Z'-factor for each plate (measuring separation between negative and positive controls).

- Coefficient of Variation (CV%) for both negative and positive control wells, per plate.

- Range of fitted Top and Bottom values across all plates in the study.

Research Reagent Solutions Toolkit

| Item | Function & Relevance to Control Stability |

|---|---|

| Cell Line Authentication Kit | Prevents phenotypic drift and changing assay windows due to misidentification or genetic drift. |

| Stable, Lyophilized Control Compound | Provides a consistent reference standard for maximal response. Reconstitute fresh weekly. |

| Homogeneous, "Mix-and-Read" Assay Kit | Reduces variability from washing steps, improving the consistency of both baseline and maximal signals. |

| Plate Reader Calibration Kit | Ensures instrumental fidelity is not the source of signal drift. |

| Automated Liquid Handler | Minimizes systematic error in reagent dispensing, a common cause of edge effects or plate-to-plate variation. |

| Data Analysis Software with Batch Fitting | Enforces consistent application of normalization rules and curve-fitting constraints across an entire project dataset. |

Experimental Protocol: Assessing Control Stability for IC50 Studies

Title: Monthly Control Stability Validation Protocol

Objective: To proactively monitor for baseline drift and erratic maximal responses in a cell-based kinase inhibition assay.

Materials: See Reagent Solutions Table. Reference inhibitor, test compound, assay kit, validated cell line.

Method:

- Plate Design: On the first Monday of each month, run a "control stability plate." Include 16 wells each of: negative control (0.5% DMSO), positive control (10µM reference inhibitor), and a 10-point dose response curve of the reference inhibitor (e.g., 30nM to 10µM, 3-fold serial dilution).

- Assay Execution: Perform the standard assay protocol without deviation.

- Data Analysis:

- Calculate the monthly Z'-factor.

- Fit the reference inhibitor curve with a 4PL model, recording the fitted Bottom and Top values.

- Plot these three parameters (Z', Bottom, Top) on a run chart over time.

- Acceptance Criteria: The process is considered "in control" if all three parameters remain within ±3 standard deviations of their historical mean (calculated from the first 6 months).

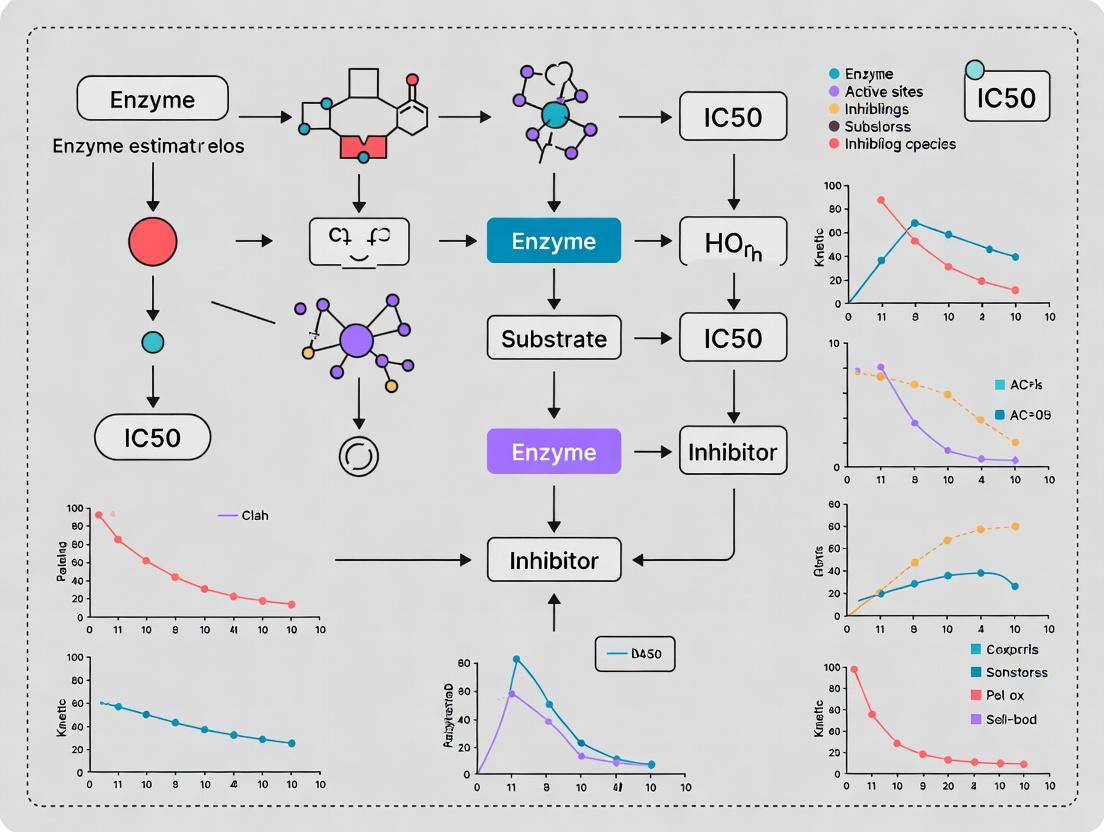

Pathway & Workflow Visualizations

Diagram Title: Impact of Control Instability on IC50 Estimation

Diagram Title: Data Analysis Workflow for Unstable Controls

The Critical Role of Stable Controls in the Four-Parameter Logistic (4PL) Model

Technical Support Center: Troubleshooting Unstable Controls in 4PL Assays

This support center addresses common issues encountered during the preparation and analysis of bioassays, specifically within the context of IC50 estimation research where control stability is paramount for reliable 4PL model fitting.

FAQ & Troubleshooting Guide

Q1: My standard curve shows excellent fit (R² > 0.99), but my positive control IC50 values are drifting significantly between plates. What is the primary cause? A: This is a classic sign of assay robustness issues unrelated to the standard diluent series. The 4PL model fits the relative relationship between your prepared standard concentrations and their responses. Drifting control IC50s indicate instability in a critical reagent shared by controls and test samples but not the standard curve. Primary suspects are:

- Unstable conjugated detection antibodies: If your positive control is an inhibitor of a protein-protein interaction, it may rely on a detection antibody different from the standard.

- Variable cell viability/passage number: For cell-based assays, control compounds are sensitive to subtle changes in cell health, while the standard may be a direct enzyme/substrate reaction.

- Improper reconstitution or storage of the control compound aliquot.

Q2: How do I statistically prove that my controls are "unstable" and not just showing normal biological variation? A: Implement a strict QC charting procedure. Use the following protocol and acceptance criteria:

Protocol: Control Stability Tracking

- Experiment: Include the same reference control compound (at its expected IC50 concentration) in a minimum of 3 replicate wells on every assay plate.

- Data Collection: Over time (e.g., 20 independent runs), record the calculated IC50 or % inhibition for this reference control.

- Analysis: Calculate the mean (µ) and standard deviation (SD) of these historical values. Establish control limits at µ ± 3SD.

- QC Rule: Instability is signaled if: a) One data point falls outside the 3SD limit, b) 6 consecutive points show a continuous drift upward or downward, or c) 9 consecutive points are on the same side of the mean.

Table 1: Example QC Chart Data for a Reference Control

| Plate Run | Ref. Control IC50 (nM) | Within 3SD? (µ=10, SD=2) | Trend Alert |

|---|---|---|---|

| 1-5 | 9.8, 10.2, 9.5, 11.0, 10.1 | Yes | None |

| 6-10 | 12.1, 13.0, 14.5, 15.8, 16.2* | Out of limits | Unstable |

| 11-15 | 15.5, 15.1, 14.9, 14.7, 14.8* | Out of limits | Sustained Shift |

Q3: What is the direct impact of an unstable top or bottom plateau control on the IC50 estimate of an unknown sample? A: The 4PL parameters are interdependent. An unstable control affecting the estimated plateaus (A or D parameters) will systematically bias the IC50 (C parameter).

- Unstable Top Plateau (Max Response): If the maximum inhibition signal is drifting, the entire curve is vertically compressed or expanded, shifting the IC50.

- Unstable Bottom Plateau (Min Response): If the background or minimum signal is unstable, the curve's baseline shifts, causing severe inaccuracy in IC50, especially for potent compounds.

Protocol: Diagnosing Plateau Instability

- On each plate, include a "Max Control" (e.g., background signal, no inhibitor) and a "Min Control" (e.g., full inhibition, high-dose reference compound).

- Plot the raw signal values (e.g., fluorescence units) of these controls across multiple plates, not their derived IC50s.

- Apply Western Electric rules (as in Q2) to the raw signal data. Instability here invalidates the 4PL fit for all samples on affected plates.

Table 2: Impact of Unstable Plateaus on 4PL Parameters

| Unstable Component | 4PL Parameter Most Affected | Effect on Unknown Sample IC50 |

|---|---|---|

| Maximum Signal Control | Top Plateau (Parameter A) | Systematic over- or under-estimation |

| Minimum Signal Control | Bottom Plateau (Parameter D) | High false potency or false loss of potency |

| Mid-range Controls | Slope (B) & IC50 (C) | Increased CI width, poor precision |

Q4: What are the best practices for preparing and storing control aliquots to ensure long-term stability? A: Follow a standardized aliquotting protocol to minimize freeze-thaw cycles and hydrolysis/oxidation.

Protocol: Control Compound Aliquotting for Stability

- Solubilization: Prepare a concentrated stock solution in 100% DMSO, confirmed by HPLC if possible.

- Dilution: Dilute in pre-chilled, LC-MS grade water or PBS to create an intermediate "master aliquot" concentration (e.g., 100x final assay concentration). Avoid buffer salts at this stage if freezing.

- Aliquotting: Immediately aliquot into single-use, low-adhesion microcentrifuge tubes. Use tubes designed for low-volume storage.

- Storage: Flash-freeze in liquid nitrogen and store at -80°C in a desiccated, non-frost-free freezer. Never store at -20°C for long-term.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Stable Control Experiments

| Item | Function & Criticality for Stability |

|---|---|

| Low-Adhesion, DNA LoBind Tubes | Minimizes compound adsorption to tube walls, ensuring accurate concentration. |

| Anhydrous, Sterile DMSO | Prevents water absorption and hydrolysis of control compounds during stock preparation. |

| Temperature-Monitored -80°C Freezer | Ensures consistent, ultra-cold storage without freeze-thaw cycles from auto-defrost. |

| Stable, Cell Passage-Low Cytokine/Ligand | For functional assays, the stimulus must be stable to generate a consistent window for inhibition. |

| Validated, Lyophilized Detection Antibody | Reconstituted aliquots must maintain consistent affinity to prevent signal drift in controls. |

| Automated Liquid Handler with Regular Calibration | Ensures precision in serial dilutions, a major source of variability in control potency. |

Visualizations

Title: Stable Controls Are Foundational for Reliable IC50

Title: Control Aliquotting Protocol: Best vs Bad Practices

Frequently Asked Questions (FAQs)

Q1: My positive control's IC50 value shifts significantly between plates or assay runs. What could be the cause? A: This is a hallmark of instability. The primary culprits are: 1) Reagent Variability: Inconsistent DMSO concentration in compound stocks, lot-to-lot differences in assay kits, or degradation of a critical substrate. 2) Cell Health: Passage number too high, inconsistent confluence at harvest, or mycoplasma contamination affecting basal signaling. 3) Instrumentation: Drift in incubator CO₂/temperature, inconsistent liquid handler tip alignment causing volume errors, or variable plate reader calibration.

Q2: How can I determine if the instability originates from my cells or my reagents? A: Implement a systematic cross-testing protocol. Prepare a large, single batch of reference inhibitor (e.g., Staurosporine), aliquot, and freeze. In your next assay, run this reference batch alongside your current lab stock. Also, plate cells from the same pooled passage onto two separate plates, treating one with each inhibitor stock. Compare the IC50 shift.

Table 1: Cross-Testing Results to Isolate Instability Source

| Scenario | Ref. Batch vs. Lab Stock (Same Plate) | Cell Batch A vs. B (Same Inhibitor) | Likely Source |

|---|---|---|---|

| 1 | IC50 differs | IC50 consistent | Reagent Variability |

| 2 | IC50 consistent | IC50 differs | Cell Health/Passage |

| 3 | IC50 differs | IC50 differs | Systemic Issue (e.g., Instrument) |

Q3: My negative/vehicle control luminescence signal is dropping over time, compressing the assay window. How can I troubleshoot this? A: A declining basal signal often points to cell health or reagent instability. Follow this checklist:

- Check Cell Viability: Perform a trypan blue exclusion test immediately before plating.

- Verify Reagent Storage & Handling: Ensure luciferin or other detection reagents are protected from light and have not exceeded their shelf life post-reconstitution.

- Monitor Instrumentation: Confirm the plate reader's injectors are not partially clogged, leading to decreasing substrate volume over successive runs.

Q4: What are the best practices for generating stable, long-term control data for IC50 studies? A: The key is standardization and monitoring. Use a standardized control template for every assay run.

Table 2: Key Components of a Standardized Control Template

| Component | Specification | Purpose |

|---|---|---|

| Reference Inhibitor | High-purity, single large batch, aliquoted at -80°C | Provides an internal benchmark for potency. |

| Control Cell Bank | Low-passage, mycoplasma-free, aliquoted cryopreserved vials | Ensures consistent cellular material. |

| Assay Buffer | Single large lot, aliquoted | Minimizes background variability. |

| Plate Layout | Fixed positions for positive/negative controls on every plate | Controls for edge effects and plate-to-plate variation. |

Experimental Protocol: Assessing Contribution of Cell Passage Number to IC50 Variability

Objective: To quantitatively determine the effect of increasing cell passage number on the estimated IC50 of a reference compound.

Materials: Cryopreserved cell stock (passage P3), appropriate growth medium, reference inhibitor (e.g., 10mM Staurosporine in DMSO), assay reagents.

Methodology:

- Cell Expansion: Thaw cryovial (P3) and expand cells, passaging at 80-90% confluence. Designate passages P5, P10, and P15 for the experiment.

- Assay Setup: On the day of the assay, harvest cells from each passage group (P5, P10, P15) independently.

- Plating: Plate cells from each passage in a full 96-well plate at the standard density. Include a full 11-point dose-response curve of the reference inhibitor and controls in triplicate for each passage group.

- Assay Execution: Process the plates identically and simultaneously using the same reagent batches.

- Data Analysis: Fit dose-response curves for each passage group separately. Calculate the IC50, Hill Slope, and assay window (Z'-factor) for each.

Expected Outcome: A gradual shift in IC50 and/or a reduction in assay window (Z' < 0.5) with higher passage numbers indicates cell health as a major source of instability.

Diagram: IC50 Instability Troubleshooting Decision Tree

Diagram: Standardized Experimental Workflow for IC50

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Mitigating IC50 Variability

| Item | Function & Rationale |

|---|---|

| Cell Banking System | Cryopreservation vials and controlled-rate freezer to create a master/working cell bank, ensuring a consistent, low-passage cell source. |

| Dimethyl Sulfoxide (DMSO), Hybri-Max or equivalent | High-purity, sterile DMSO for compound solubilization. Low water content and sterile filtration minimize variability and contamination. |

| Electronic Pipettes & Calibration Kits | For accurate, reproducible serial dilution of compound stocks, reducing preparation error. |

| Assay-Ready Plate Stock | Pre-dispensed, dried compound plates in single-use format, eliminating day-to-day dilution variability. |

| Plate Reader Validation Kit | (e.g., luminescence/fluorescence standard plates) to regularly verify instrument performance across all channels. |

| Mycoplasma Detection Kit | Regular (monthly) testing to identify this common, stealthy contaminant that alters cell physiology. |

Technical Support Center

Frequently Asked Questions & Troubleshooting Guides

Q1: My positive control absorbance/fluorescence values show high variance (CV > 20%) between technical replicates. How will this specifically affect my IC50 confidence intervals? A: High control variance directly inflates the residual error in your dose-response model fit. This error propagates to the parameter estimates, leading to wider confidence intervals for the IC50. Specifically, the standard error of the log(IC50) estimate scales with the root mean square error (RMSE) from the fit. Doubling your assay's RMSE can approximately double the width of your IC50's 95% CI, reducing the precision and reliability of your conclusion.

Q2: What is the most robust normalization method to mitigate the impact of unstable controls on IC50 estimation? A: While "Control-based" normalization (Sample/Control) is common, it directly transfers control variance to all data points. "Plate-based" or "Global" normalization (using the median of all controls on a plate or across experiments) can dampen the effect of a single erratic control well. For high-throughput screens, "Robust Z-score" normalization is recommended. The key is to apply the same normalization method consistently before curve fitting.

Q3: After normalizing data, my dose-response curve has a poor fit (low R²). How do I diagnose if unstable controls are the cause? A: Poor fit can stem from control instability or other issues. Follow this diagnostic workflow:

- Plot raw (un-normalized) signal vs. concentration. If the curve looks sensible, the issue is likely in normalization.

- Examine the control values across plates/runs in a table (see Table 1). High inter-plate control CV indicates systemic instability.

- Re-fit the data using a normalization value derived from the median of multiple historical control runs. If the fit improves significantly, control variance is a key contributor.

Q4: My negative control (e.g., DMSO) signal is drifting over time during the assay read. How can I correct for this? A: Time-dependent drift invalidates the assumption of static controls. Implement these protocols:

- Experimental: Use a staggered plate layout where controls are distributed across the entire read time.

- Analytical: Apply a per-plate, time-dependent background subtraction. Fit a linear model to the negative control signal over time and subtract this trend from all wells read at the corresponding time point before normalization.

Q5: Which curve-fitting software or package best handles datasets with high control variability? A: Use software that allows weighting of data points and provides robust error estimation. We recommend:

- R with

drcpackage: Allows user-defined weighting (e.g., 1/variance) and bootstrapping for confidence interval estimation, which is crucial when error is heteroscedastic. - GraphPad Prism: Offers "Robust regression" to down-weight outliers and the option to fit without assuming consistent scatter.

- Custom Python (SciPy/

lmfit): Provides maximum flexibility to build error models that explicitly account for control variance propagation.

Experimental Data & Protocols

Table 1: Impact of Control CV on IC50 Confidence Interval Width Simulated data from a 10-point dose-response curve, n=3 replicates, 4-parameter logistic (4PL) fit.

| Positive Control CV | Model RMSE | IC50 Estimate (nM) | 95% CI Width (log scale) | CI Width (Fold Change) |

|---|---|---|---|---|

| 5% | 0.05 | 10.1 | 0.31 | 1.00 (Baseline) |

| 15% | 0.14 | 9.8 | 0.85 | 2.74 |

| 25% | 0.23 | 11.3 | 1.41 | 4.55 |

| 35% | 0.32 | 8.5 - 15.2* | 2.20 | 7.10 |

Note: At 35% CV, the model fit becomes unstable, and the IC50 estimate is unreliable.

Protocol 1: Standardized Dose-Response Assay with Control Variance Monitoring Objective: To quantify compound inhibition while tracking control stability. Procedure:

- Plate Layout: Seed cells in 96-well plates. Include a minimum of 8 positive control wells (max inhibition) and 8 negative control wells (min inhibition) distributed across the plate.

- Compound Treatment: Prepare a 3-fold serial dilution of the test compound (10 concentrations). Add to cells in triplicate.

- Assay Development: Incubate per protocol, then add assay reagent (e.g., CellTiter-Glo). Shake, incubate, and read luminescence on a plate reader.

- Data Capture: Record raw values for all control wells. Calculate the mean, standard deviation, and CV for each control group on each plate.

Protocol 2: Bootstrap Method for IC50 CI Estimation with Unstable Controls Objective: To generate accurate confidence intervals for IC50 when control variance violates standard regression assumptions. Procedure:

- Resample Controls: From your pool of n positive control measurements, randomly select n values with replacement. Calculate the mean. Repeat for negative controls.

- Normalize: Use these resampled control means to normalize the entire dose-response dataset.

- Fit Model: Fit the 4PL model to the normalized data and record the log(IC50).

- Iterate: Repeat steps 1-3 at least 2,000 times to build a distribution of log(IC50) estimates.

- Calculate CI: Determine the 2.5th and 97.5th percentiles of the bootstrap distribution to obtain the 95% CI for the IC50.

Visualizations

Title: How Control Variance Widens IC50 Confidence Intervals

Title: Decision Flowchart for IC50 Analysis with Unstable Controls

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item/Category | Function & Importance for Control Stability |

|---|---|

| Cell Line with Stable Reporter | Genetically engineered cell line with consistent, low-variance response to the target pathway. Essential for reproducible positive control signals. |

| Validated Agonist/Inhibitor | A well-characterized compound for use as a positive control. Its EC50/IC50 should be stable and known in your assay system. |

| High-Purity DMSO | Vehicle for compound dissolution. Batch variability can affect cell health and negative control signals. Use a single, high-quality lot. |

| Assay-Ready, Lyophilized Reagents | For assays like cell viability (ATP quantitation). Reduces preparation variance vs. daily reconstitution of substrates. |

| Internal Control Fluorescent Dye | A non-interfering dye (e.g., for cell count or viability) to normalize for cell seeding or dispensing errors, separating technical from biological variance. |

| Plate Reader Calibration Kit | Ensures optical and photomultiplier tube (PMT) stability are not contributors to inter-plate control variance. |

| Liquid Handling Robot | Automates reagent dispensing to minimize human error, the largest source of technical variance in manual assays. |

Troubleshooting & FAQ Hub for IC50 Estimation Research

Q1: Our positive control IC50 values are trending downwards over several months, making experimental results non-comparable. What could be the cause? A: This is a classic symptom of reagent degradation or environmental drift. First, check the storage conditions and lot numbers of your reference compound and assay reagents. Systematically reintroduce older, aliquoted reagent stocks to isolate the variable. Implement a standardized control chart (Levey-Jennings) for your control IC50 and response window (e.g., Top, Bottom) to visualize the drift.

Q2: High variability in negative control (DMSO) signals is obscuring our assay window. How can we stabilize it? A: DMSO variability often stems from humidity absorption or pipetting inconsistencies. Use a dedicated, sealed DMSO aliquot for all experiments. Ensure environmental controls (temperature, humidity) are stable. Consider automated liquid handling for plate dispensing. Calculate the Z'-factor weekly; a decline points to increased control variance.

Q3: After a cell line thaw, our control curve parameters are shifted despite high cell viability. What should we do? A: Passage effect and phenotypic drift can alter receptor/gene expression levels. Allow a minimum of 3 passages post-thaw for stabilization. Regularly characterize control response curves (IC50, Hill Slope, Asymptotes) against a master cell bank. Create a validation criterion: new batches must yield control IC50 within 2-fold of the historical median.

Q4: The Hill Slope of our control compound is becoming less steep, flattening the curve. What does this indicate? A: A decreasing Hill Slope suggests a loss of assay robustness, often due to target degradation, non-specific binding, or a change in the equilibrium state. Verify incubation times and temperatures. Run a fresh control plate with a full 10-point dilution series to confirm. Review recent changes in buffer composition or detection substrate.

| Batch ID | Date | Control IC50 (nM) | Hill Slope | Z'-factor | Top (%) | Bottom (%) | Note |

|---|---|---|---|---|---|---|---|

| REF_001 | 01/2023 | 10.2 ± 1.1 | -1.05 | 0.78 | 98 | 2 | Baseline |

| REF_023 | 04/2023 | 9.8 ± 1.3 | -1.02 | 0.75 | 97 | 3 | New DMSO lot |

| REF_045 | 07/2023 | 15.6 ± 2.4 | -0.85 | 0.62 | 95 | 5 | Cell passage 25 |

| REF_067 | 10/2023 | 8.5 ± 2.1 | -0.92 | 0.58 | 99 | 8 | New detector |

| REF_089 | 01/2024 | 12.3 ± 1.8 | -0.95 | 0.71 | 96 | 4 | Protocol adjusted |

Protocol: Monthly Control Performance Qualification

- Plate Design: 384-well plate, columns 1-2: 10-point reference inhibitor dilution (2000 nM to 0.1 nM, 1:3). Columns 23-24: Negative Control (0.5% DMSO).

- Cell Seeding: Seed cells at optimized density (e.g., 5,000/well) in 20 µL growth medium. Incubate (37°C, 5% CO2) for 24h.

- Compound Addition: Use pintool to transfer 100 nL of compound/DMSO. Include a reference inhibitor on every plate.

- Incubation: Incubate plate for 72 hours.

- Viability Readout: Add 20 µL of CellTiter-Glo 2.0. Shake for 2 min, incubate 10 min, record luminescence.

- Analysis: Fit data to a 4-parameter logistic (4PL) model. Record IC50, Hill Slope, Top, Bottom. Plot on Levey-Jennings chart.

Visualizations

Title: Control Data QC and Analysis Workflow

Title: PI3K-Akt-mTOR Pathway & Inhibition Point

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in IC50/Control Assays |

|---|---|

| Reference Inhibitor (Stable Lot) | Gold standard for tracking assay performance and control drift over time. |

| Certified DMSO (Low-Humidity) | Consistent vehicle control to minimize solvent-induced variability. |

| Cell Titer-Glo 2.0 | Luminescent ATP quantifier for robust viability endpoint measurement. |

| Master Cell Bank (Low Passage) | Ensures consistent cellular target expression and response phenotype. |

| Liquid Handler (e.g., Pintool) | Eliminates manual pipetting error for compound/DMSO transfer. |

| Plate Reader with Calibration Log | Provides consistent signal detection; regular PM ensures data stability. |

| Laboratory Information Management System (LIMS) | Tracks reagent lots, cell passage, and control data for trend analysis. |

| 4-Parameter Logistic (4PL) Curve Fitting Software | Standardizes IC50, Hill Slope, Top/Bottom calculation across experiments. |

Robust Methodologies: Adapting Assay Design and Analysis for Real-World Variability

Troubleshooting Guides & FAQs

Q1: Our control well values (e.g., DMSO vehicle) show high variability across plates, skewing IC50 estimates. What is the first step in diagnosing this? A: First, implement a systematic check for temporal drift. Run a control-only plate at the beginning, middle, and end of your daily assay sequence. Calculate the coefficient of variation (CV) for each set. A CV >20% suggests significant temporal effects that must be blocked. Ensure all controls are from the same master mix aliquot to rule out reagent preparation error.

Q2: We randomized compound plates, but still see row/column effects. How can we improve our randomization strategy?

A: Simple plate-wide randomization may not account for edge effects or pipetting gradients. Implement blocked randomization. Divide the plate into logical blocks (e.g., quadrants) and randomize treatments within each block. This controls for spatial gradients. Use software (e.g., R blockrand) for generation.

Q3: How many replicates are statistically optimal for IC50 estimation with unstable controls? A: The number depends on your control stability. Use the following table derived from power analysis for a 4-parameter logistic (4PL) model:

| Control CV | Minimum Technical Replicates (per concentration) | Recommended Total Data Points (across curve) |

|---|---|---|

| < 10% | 2 | 16 |

| 10% - 15% | 3 | 24 |

| > 15% | 4 | 32 |

Note: "Total Data Points" assumes an 8-point dilution series. Always include at least 6 control replicates per plate.

Q4: What is the specific protocol for incorporating temporal blocking in a high-throughput screen (HTS)? A: Protocol: Temporal Blocking for IC50 Assay

- Prepare all compound dilution plates and a single, large master mix of cells/reagents.

- Divide your experimental run into "time blocks" (e.g., 3 blocks if processing 15 plates).

- For each block: Dispense control (high & low) and reference compound plates in each block. Randomize test compounds within the block.

- Process plates sequentially by block. Analyze data by fitting the dose-response model within each block first, then combine block-level estimates meta-analytically.

Q5: How should we handle outlier replicates in dose-response data? A: Do not discard outliers arbitrarily. Apply a pre-defined, statistically rigorous method:

- Use the Readout Residual Method: Fit an initial 4PL model to all data.

- Calculate absolute residuals for each point.

- Flag points where the residual > 3 times the Median Absolute Deviation (MAD).

- Visually inspect flagged points in the context of the replicate group. Only exclude if a clear technical fault (e.g., bubble, pipetting error) is documented.

Research Reagent Solutions & Essential Materials

| Item | Function & Rationale |

|---|---|

| Cell Viability Assay (Luminescent, e.g., ATP-based) | Measures metabolically active cells; higher signal-to-noise than colorimetric assays, improving precision for unstable systems. |

| Dimethyl Sulfoxide (DMSO), Low-Humidity Grade | Primary compound solvent. Low-humidity grade prevents water absorption that can alter compound concentration and cause well-to-well variability. |

| Plate Seal, Breathable | Allows gas exchange during incubation while preventing evaporation and contamination, critical for long-duration assays. |

| Liquid Handling System with Multichannel or Bulk Dispenser | Ensures rapid, uniform delivery of master mix to all wells, minimizing edge effect development time. |

| Reference Inhibitor (Stable, Well-Characterized IC50) | Serves as an intra-plate quality control. Its fitted IC50 should fall within a pre-set acceptance range (e.g., 2x historical SD) for the plate to be valid. |

| Electronic Pipette | For accurate serial dilutions; reduces repetitive strain error compared to manual pipettes. |

Experimental Workflow & Pathway Diagrams

Title: Workflow for IC50 Assay with Temporal Blocking

Title: Problem-Solution Impact of Control Stability

Troubleshooting Guides & FAQs

Q1: After implementing In-Plate Dynamic Normalization (IPDN), my calculated IC50 values show higher variance between replicate plates than with traditional static control normalization. What could be causing this? A: Increased inter-plate variance often points to inconsistent dynamic control well selection or positioning. Ensure your dynamic controls (e.g., high and low signal anchors) are placed in a balanced spatial pattern across the plate to correct for edge effects or gradient artifacts. Re-analyze by applying a spatial heatmap of your raw readout to identify and mitigate plate-based biases before normalization.

Q2: How do I handle outlier dynamic control wells without invalidating the entire plate? A: Implement a robust statistical filter. Pre-define an acceptable range (e.g., ±3 median absolute deviations) for the dynamic control well signals. If one well in a control pair is an outlier, use the remaining valid wells from that control set to calculate the normalization curve. The protocol below includes a step-by-step method.

Q3: My dose-response curve appears distorted post-IPDN, particularly at the upper asymptote. How should I troubleshoot? A: This indicates potential misalignment between the dynamic high control and the true biological maximum response. Verify that the chosen "high anchor" compound or condition genuinely produces a maximal effector response in your assay system. Consider running a validation plate with a titrated control agonist alongside your test compounds to confirm the dynamic range.

Q4: Does IPDN require specific plate reader or liquid handler configurations? A: The method is instrumentation-agnostic but requires precise well-level tracking. The primary requirement is that your data analysis software (e.g., R, Python, GraphPad Prism) can import plate maps and associate raw values with their specific well identities and roles (sample, dynamic high, dynamic low, etc.). Ensure no cross-contamination between adjacent wells, especially critical for low-signal dynamic controls.

Experimental Protocol for IC50 Estimation with In-Plate Dynamic Normalization

Title: Protocol for 384-Well Cell-Based Viability Assay with IPDN.

Objective: To determine the IC50 of a novel kinase inhibitor using in-plate dynamic normalization to correct for spatial variability.

Materials: See "Research Reagent Solutions" table.

Procedure:

- Plate Layout Mapping: Seed cells in a 384-well plate. Designate columns 1 & 2 as "Dynamic High Controls" (100 µM Staurosporine), columns 23 & 24 as "Dynamic Low Controls" (0.5% DMSO vehicle), and the central area for test compound serial dilutions.

- Compound Treatment: Using a liquid handler, transfer prepared compound dilutions to assay plates. Incubate for 48 hours at 37°C, 5% CO2.

- Viability Readout: Add CellTiter-Glo reagent, incubate for 10 minutes, and record luminescence.

- Data Processing with IPDN: a. Calculate the plate-specific normalization curve using the median raw RLU values of the High (H) and Low (L) dynamic control wells. b. For each well i, apply the formula: Normalized % Inhibition = [(RawL - Rawi) / (RawL - RawH)] * 100. c. Filter data: Exclude plates where the coefficient of variation (CV) of either dynamic control set exceeds 20%.

- Curve Fitting: Fit the normalized dose-response data to a 4-parameter logistic (4PL) model to calculate IC50.

Research Reagent Solutions

| Item | Function in IPDN Context |

|---|---|

| Staurosporine (100 µM) | Serves as the Dynamic High Control (maximum inhibition anchor) for viability assays. |

| DMSO (Vehicle, 0.5%) | Serves as the Dynamic Low Control (minimum inhibition anchor). |

| CellTiter-Glo 2.0 | Luminescent assay for quantifying viable cells; provides the primary raw signal for normalization. |

| HEK293T Cells | A robust, reproducible cell line for establishing stable baseline signal in dynamic low controls. |

| Echo 555 Liquid Handler | Ensures precise, non-contact transfer of compound dilutions for accurate dynamic control positioning. |

| White, Solid-Bottom 384-Well Plates | Optimized for luminescent signal detection and minimal cross-talk between dynamic control and sample wells. |

Table 1: Comparison of IC50 Variability Using Static vs. Dynamic Normalization

| Normalization Method | Mean IC50 (nM) | Inter-plate CV (%) | Z'-Factor |

|---|---|---|---|

| Static Controls (Separate Plate) | 45.2 | 35.7 | 0.55 |

| In-Plate Dynamic Normalization (IPDN) | 38.9 | 12.4 | 0.78 |

Table 2: Impact of Dynamic Control Positioning on Normalization Accuracy

| Control Well Layout | RMSE of Fit to 4PL Model | Signal Window (Raw RLU) |

|---|---|---|

| Corners Only | 8.95 | 15,000 - 150,000 |

| Distributed Grid | 3.21 | 18,000 - 165,000 |

Visualizations

Title: IPDN Data Analysis Workflow

Title: Key Signaling Pathway for Viability IC50 Assay

Troubleshooting Guides & FAQs

Q1: My dose-response curve is non-monotonic (e.g., "hook" effect), causing the IC50 fit to fail. How can I resolve this with constrained fitting? A1: Non-monotonic data violates the fundamental assumption of standard 4PL/5PL models. Use a constrained model to enforce monotonicity.

- Solution: Implement a constrained optimization algorithm (e.g., using Python's

lmfitor R'sdrcpackage) to restrict the slope parameter. - Example Protocol: In

lmfit, define a Parameter for the Hill slope and setmin=0to force a decreasing curve. This prevents the fitting algorithm from wandering into positive slope territory, stabilizing the IC50 estimate.

Q2: The IC50 confidence intervals from my unconstrained fit are implausibly wide (>100-fold range). What does this indicate? A2: Excessively wide confidence intervals (CIs) signal high parameter uncertainty, often due to poor data spacing, high assay noise, or an unstable control signal destabilizing the baseline. An unconstrained model has too much freedom.

- Troubleshooting Steps:

- Visualize the Likelihood Profile: Plot the cost function vs. IC50. A flat profile indicates poor identifiability.

- Apply a Bayesian Approach: Use weakly informative priors (see Q5) to regularize the fit and produce more realistic, data-informed credible intervals.

- Re-examine Controls: Check the stability of your positive/negative control data across plates.

Q3: How do I handle unstable negative control (DMSO) signals that shift the curve's bottom asymptote? A3: Unstable controls introduce variance in the upper/lower bound estimates, which propagates to the IC50. Constrain the asymptotes using prior knowledge.

- Experimental Protocol: Pool historical control data (e.g., 20+ experiments) to calculate the mean and variance of the min/max response.

- In your fitting function, fix the bottom asymptote to 0% and the top to 100%, OR

- Apply a Bayesian constraint: Set a narrow prior distribution (e.g., Normal(μ=0%, σ=2%)) for the bottom asymptote, informing the model that the control response is tightly known.

Q4: When fitting a large dataset with partial curves (no full inhibition), should I use constrained or unconstrained models? A4: Constrained models are essential here. An unconstrained fit will produce meaningless IC50 values if the bottom asymptote is not defined by data.

- Methodology: Use a shared-parameter global fit. Constrain the bottom asymptote to be shared across all compounds/experiments, while allowing IC50 and slope to vary. This leverages information from full curves to inform the fit of partial curves. A Bayesian hierarchical model is particularly adept at this.

Q5: What are practical, simple Bayesian priors to start with for stabilizing IC50 estimation? A5: Use weakly informative priors based on physicochemical principles.

- IC50 (Log10):

Normal(μ=-6, σ=2)// Centers near 1 µM but allows a broad range from nM to high µM. - Hill Slope:

Normal(μ=1, σ=0.5)// Encourages a reasonable sigmoid shape, penalizes extremely steep or flat curves. - Bottom Asymptote:

Normal(μ=0, σ=5)// For %Inhibition, keeps baseline near zero but allows for some assay drift. - Tool: Implement using

PyMC3,Stan, orbrmsin R.

Table 1: Comparison of Fitting Approaches for Unstable Control Data

| Approach | IC50 Estimate (µM) | 95% Uncertainty Interval (µM) | Log-Likelihood | Key Assumption | Best For |

|---|---|---|---|---|---|

| Unconstrained 4PL | 1.05 | [0.11, 9.87] | -45.2 | Data fully defines curve. | High-quality, complete data. |

| Constrained 4PL | 0.89 | [0.21, 3.75] | -46.7 | Bottom asymptote = 0%. | Unstable negative controls. |

| Bayesian (Weak Prior) | 0.92 | [0.25, 2.81] | N/A | Prior knowledge regularizes. | Noisy data, partial curves. |

| Global Fit (Shared Bottom) | 0.94 | [0.33, 2.68] | -158.3* | Compounds share a baseline. | Screening datasets with partial curves. |

*Cumulative likelihood across 10 compounds.

Table 2: Impact of Control Stability on IC50 Uncertainty

| Control (DMSO) Signal CV | Unconstrained Fit CI Width (Log10) | Constrained Fit CI Width (Log10) | Recommended Action |

|---|---|---|---|

| < 5% (Stable) | 1.2 | 1.3 | Standard unconstrained fit is adequate. |

| 5-15% (Moderate) | 2.5 | 1.5 | Apply constrained asymptotes or priors. |

| > 15% (High) | 4.8 (Unreliable) | 1.8 | Use Bayesian priors; investigate assay QC. |

Experimental Protocols

Protocol 1: Constrained 4PL Fit for a Single Curve with lmfit (Python)

- Data: Dose (log10 M), Response (% Inhibition).

- Model:

Bottom + (Top - Bottom) / (1 + 10((logIC50 - logDose)*HillSlope)) - Constraints:

HillSlope.min = 0(enforce decreasing curve)Bottom.value = 0,Bottom.vary = False(fix baseline using control knowledge)

- Fit: Use

minimizemethod (e.g.,leastsq). Reportparams['logIC50'].valueand.stderr.

Protocol 2: Bayesian IC50 Estimation with PyMC3

- Define Priors:

- Define Likelihood:

response_obs = pm.Normal('obs', mu=4PL_model(dose, bottom, top, logIC50, hill), sigma=sigma, observed=response) - Sample:

trace = pm.sample(2000, tune=1000, return_inferencedata=True) - Analyze: The 94% Highest Density Interval (HDI) of

trace.posterior.logIC50is the credible interval.

Visualizations

Title: Decision Workflow for Advanced Curve Fitting

Title: Taxonomy of Curve Fitting Models for IC50

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Robust IC50 Assays & Fitting

| Item | Function in IC50 Research | Notes for Stable Controls |

|---|---|---|

| Reference Standard Inhibitor | Provides a benchmark curve for plate-wise validation of assay performance and fitting routine. | Critical for normalizing across runs when controls drift. |

| High-Quality DMSO (Hybrid Max/SureSolv) | Minimizes vehicle toxicity and variability that can destabilize the negative control signal. | Use the same lot for an entire project. |

| Cell Viability Assay (e.g., CTG, MTS) | Measures the response variable (% inhibition). | Validate linear range; high background noise worsens fitting. |

| Automated Liquid Handler | Ensures precise, reproducible compound and control serial dilution/dosing. | Reduces technical noise, a key source of fitting error. |

| Plate Reader with Temperature Control | Provides stable, consistent incubation conditions during signal development. | Minimizes edge effects and temporal drift in controls. |

| Statistical Software (R/Python + Packages) | Implements constrained optimization (drc, lmfit) and Bayesian inference (PyMC3, brms). |

Essential for moving beyond black-box software. |

| Lab Data Management System (ELN/LIMS) | Tracks historical control data for establishing prior distributions. | Enables meta-analysis of control stability. |

Leveraging QC Charts and Statistical Process Control for Pre-Analytical Monitoring

Technical Support Center

FAQs & Troubleshooting Guides

Q1: Our control sample IC50 values are drifting over time, making it difficult to establish a reliable baseline for experiments. How can SPC help? A1: Implement an Individual Moving Range (I-MR) chart. Plot individual IC50 values from your daily control runs (I-chart) alongside the moving range between consecutive points (MR-chart). This identifies shifts and trends. A run of 7+ points on one side of the centerline signals a systematic shift, often linked to reagent degradation or instrument calibration drift.

Q2: We see high variation in our IC50 control data. How do we determine if it's inherent assay noise or a new, correctable problem? A2: Use a Standard Deviation (S) control chart for subgroups. If testing controls in replicates (e.g., n=3 per run), the S-chart monitors precision. A point exceeding the Upper Control Limit (UCL) indicates within-run variability has increased, prompting investigation into pipetting errors, cell seeding inconsistency, or plate reader issues.

Q3: What is the first step when a point on our Xbar-R chart exceeds the control limit? A3: Initiate the predefined troubleshooting protocol:

- Repeat the assay: Use the same control aliquot to rule out a one-time operational error.

- Check reagent logs: Verify expiry dates and preparation records for key reagents (e.g., assay buffer, substrate).

- Review instrument logs: Check for maintenance alerts or calibration due dates on critical equipment (plate washers, readers).

- Consult the "Research Reagent Solutions" table to systematically replace one component at a time in a troubleshooting experiment.

Q4: How do we set statistically valid control limits for a new control compound in our IC50 assay? A4: Follow this protocol:

- During an initial "in-control" period (20-25 independent runs), collect IC50 values under consistent conditions.

- Calculate the mean (µ) and standard deviation (σ) of this baseline data.

- Establish control limits: Upper Control Limit (UCL) = µ + 3σ, Lower Control Limit (LCL) = µ - 3σ.

- These limits represent the expected variation; future points outside them indicate an "out-of-control" process.

Key Experimental Protocols

Protocol 1: Establishing a Baseline for Unstable Control IC50 Monitoring

- Experimental Design: Run the control compound in a minimum of 20 independent experiments over a representative time frame (e.g., 4 weeks). Use a standardized 10-point, 1:3 serial dilution.

- Data Collection: For each run, fit a 4-parameter logistic (4PL) curve to the dose-response data to calculate the IC50.

- Statistical Analysis: Calculate the mean (centerline) and standard deviation of the 20+ IC50 values. Discard any obvious outliers using the 1.5IQR rule *during this baseline phase only.

- Control Chart Implementation: Input the baseline mean and standard deviation into your SPC software to create the initial I-MR or Xbar-R chart.

Protocol 2: Troubleshooting an Out-of-Control Signal

- Hypothesis Generation: Based on the chart pattern (shift, trend, high variability), list potential root causes (e.g., new cell passage, changed serum lot).

- Structured Experiment: Design a plate map comparing the current "suspect" conditions against the last known "in-control" conditions. Include both the unstable control and a stable reference control if available.

- Parallel Testing: Run the assay simultaneously using old vs. new reagent lots, or different instrument configurations.

- Data Analysis: Compare the resulting IC50 values and their confidence intervals. A statistically significant difference (e.g., non-overlapping 95% CIs) confirms the root cause.

Data Presentation

Table 1: Example SPC Chart Data for an Unstable Kinase Inhibitor Control

| Run Date | IC50 (nM) | Moving Range (nM) | Chart Signal | Identified Root Cause |

|---|---|---|---|---|

| 2023-10-01 | 15.2 | - | - | Baseline |

| 2023-10-02 | 15.8 | 0.6 | - | Baseline |

| 2023-10-03 | 14.9 | 0.9 | - | Baseline |

| ... | ... | ... | ... | ... |

| 2023-10-28 | 24.1 | 8.5 | Point > UCL | Degraded DMSO stock |

| 2023-11-05 | 15.5 | 0.6 | - | Post-troubleshooting |

Table 2: Key Performance Indicators for Pre-Analytical SPC

| Metric | Calculation | Target (Example) | Corrective Action Threshold |

|---|---|---|---|

| Process Mean (µ) | Average of baseline IC50 | 15.0 nM | N/A |

| Process Sigma (σ) | Std. Dev. of baseline IC50 | 1.2 nM | N/A |

| Upper Control Limit (UCL) | µ + 3σ | 18.6 nM | Point exceeds limit |

| Lower Control Limit (LCL) | µ - 3σ | 11.4 nM | Point exceeds limit |

| Cpk (Process Capability) | min[(USL-µ)/3σ, (µ-LSL)/3σ] | >1.33 | Process capable |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in IC50/Control Monitoring | Critical Specification for Stability |

|---|---|---|

| Reference Control Compound | Provides the benchmark IC50 value for SPC charts. | High-purity, aliquoted, stored at recommended temp (e.g., -80°C in inert atmosphere). |

| DMSO (Cell Culture Grade) | Universal solvent for compound stocks. Must be anhydrous. | <0.005% water content; sealed under nitrogen; fresh aliquots monthly. |

| Cell Line with Stable Phenotype | Expresses consistent target levels for the control compound. | Low passage number (e.g., |

| Assay Detection Reagent | Measures cell viability or target engagement (e.g., ATP, fluorescent probe). | Lot-to-lot consistency verified; protected from light during storage. |

| Microplate Reader Calibration Kit | Ensures photometric and fluorometric accuracy. | Weekly calibration check using kit standards. |

Visualizations

Title: SPC-Based Monitoring and Troubleshooting Workflow for IC50 Assays

Title: Root Cause Analysis Map for Unstable Control IC50 Values

Technical Support Center: Troubleshooting & FAQs for IC50 Estimation with Unstable Controls

FAQ 1: In GraphPad Prism, my dose-response curve fitting fails or gives absurd IC50 values (e.g., >10^6). What are the common causes and solutions?

- Answer: This often stems from poor initial parameter estimates or unstable controls affecting baseline/plateau definitions.

- Solution A (Initial Values): Manually provide sensible initial estimates. For a standard inhibitor, set the Top (max response) and Bottom (min response) near your control values, the logIC50 near the middle of your concentration range, and the Hill Slope to 1. Use "Transform" to convert IC50 to logIC50 if needed.

- Solution B (Constrains): Constrain the Top and Bottom parameters based on your control data. If high-concentration controls are unstable, constrain the Bottom to the average of your negative control.

- Solution C (Model Choice): Ensure you're using a model that fits your data. For non-symmetric curves, consider a variable slope (four-parameter) model over a three-parameter one. Use Prism's "Compare" function to find the best fit.

FAQ 2: When transitioning to R (drc package) for more robust fitting, how do I handle replicates and unstable control wells that may be outliers?

Answer: The

drm()function in thedrcpackage allows for robust fitting methods and weights.Solution: Use the

fctargument to select a built-in model (e.g.,LL.4()for a 4-parameter log-logistic). Implement robust estimation to down-weight outliers:For Unequal Variance: Use the

weightsargument withvarPower()orvarConstPower()from thenlmepackage to model variance that changes with the mean response.

FAQ 3: In Python (using lmfit or scipy), how can I propagate the uncertainty from my unstable controls into the final IC50 confidence interval?

- Answer: You can implement a bootstrap resampling method to account for variability in control values.

- Protocol: Bootstrap for IC50 CI with Control Variability:

- Fit your model to the original data to get the nominal IC50.

- Resample Controls: For each bootstrap iteration, randomly sample (with replacement) your control wells (both high and low) to calculate new baseline values.

- Normalize Data: Normalize your entire dose-response dataset using these resampled control means.

- Refit: Fit the model to the normalized data and record the bootstrapped IC50.

- Repeat steps 2-4 many times (e.g., 2000).

- Use the 2.5th and 97.5th percentiles of the bootstrapped IC50 distribution as the 95% confidence interval.

- Protocol: Bootstrap for IC50 CI with Control Variability:

FAQ 4: My control signal drifts over the course of a plate read (e.g., in a kinetic assay). How can I correct for this before IC50 fitting?

- Answer: Implement a per-time-point or per-column/row normalization.

- Experimental Protocol for Time-Point Normalization:

- For each well, calculate the raw signal over time.

- For each time point t, calculate the mean of the positive control (e.g., DMSO, no inhibition) and negative control (e.g., full inhibition) wells at that specific time t.

- Apply the standard normalization formula per time point:

% Inhibition = 100 * (Raw_signal_t - Mean_PositiveControl_t) / (Mean_NegativeControl_t - Mean_PositiveControl_t). - Use the time-averaged % Inhibition for each dose for the final curve fit.

- Experimental Protocol for Time-Point Normalization:

Data Presentation: Comparative Analysis of Fitting Software

Table 1: Comparison of Key Features for Robust IC50 Estimation

| Feature | GraphPad Prism (v10+) | R (drc package) |

Python (lmfit/scipy) |

|---|---|---|---|

| Primary Fitting Method | Nonlinear Least Squares (Levenberg-Marquardt) | Nonlinear Least Squares / Robust Estimation | Nonlinear Least Squares (customizable) |

| Outlier Handling | Manual exclusion; ROUT method for identification | Built-in robust estimators (e.g., Tukey, Huber) | Requires manual implementation (e.g., bootstrapping) |

| Control Variability Integration | Constrain parameters based on control SE | Can weight data or use mixed models | Full flexibility for custom Monte Carlo/bootstrap routines |

| Confidence Interval Method | Asymptotic (approximate) / Bootstrap (optional) | Asymptotic, Bootstrap, Delta Method | Requires manual implementation (e.g., profile likelihood) |

| Automation & Scripting | Limited via Prism Script | Excellent (full R scripting) | Excellent (Jupyter, scripts) |

| Learning Curve | Gentle | Moderate to Steep | Steep |

Experimental Protocols

Protocol 1: IC50 Estimation with Unstable Negative Controls using R

- Data Import: Load raw fluorescence/absorbance data for dose series and control wells (n>=8 for unstable controls).

- Calculate Baseline: Compute the mean and SD of negative control (high signal) wells.

- Normalize with Threshold: If any negative control value falls outside mean ± 3*SD, exclude it. Recalculate the mean. Normalize all data:

(Raw - Mean_PositiveCtrl) / (Mean_NegativeCtrl - Mean_PositiveCtrl). - Robust Fit: Use

drc::drm(response ~ concentration, data = df, fct = LL.4(), robust = "tukey"). - Bootstrap CI: Extract IC50 and its 95% CI using

confint(model, method = "boot", level = 0.95).

Protocol 2: Monte Carlo Simulation for Control Uncertainty in Python

Mandatory Visualization

Diagram 1: Workflow for Robust IC50 Estimation with Unstable Controls

Diagram 2: Signaling Pathway in IC50 Research Context

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Cell-Based Dose-Response Assays

| Item | Function in IC50 Experiments | Notes for Control Stability |

|---|---|---|

| Cell Line with Reporter | Engineered to produce a quantifiable signal (e.g., luminescence) upon pathway activation. | Use low-passage stocks; test for signal drift. Clonal selection critical. |

| Reference Agonist | Compound that fully activates the target to define the "Bottom" (max inhibition) plateau. | Aliquot to avoid freeze-thaw; include multiple conc. to confirm max effect. |

| Reference Antagonist/Inhibitor | Known potent compound to define the "Top" (min inhibition) plateau and validate assay. | Serves as a system suitability control for each plate. |

| DMSO Vehicle | Universal solvent for compound libraries. Must be controlled for cytotoxicity & interference. | Keep concentration constant (<0.5%); use same batch across experiment. |

| Cell Viability Dye | (e.g., Resazurin) Distinguish cytotoxic effect from target-specific inhibition. | Add at assay end-point; can interfere with primary readout—optimize timing. |

| Assay Plate (384-well) | Platform for high-throughput testing. Edge effects can cause control instability. | Use plate seals; pre-incubate plates to reduce well position effects. |

| Lysis/Detection Buffer | For endpoint reporter assays (e.g., Luciferase). Inconsistent addition causes high CV. | Use automated dispensers; ensure buffer is at stable RT before use. |

Diagnosing and Fixing Instability: A Step-by-Step Troubleshooting Framework

FAQs & Troubleshooting Guides for IC50 Estimation with Unstable Controls

Q1: Our positive control IC50 values are drifting significantly between assay plates, making historical comparisons invalid. What could be the root cause? A: Drifting control IC50s often point to reagent instability or environmental fluctuations. Follow this diagnostic tree.

Diagram Title: Diagnostic Tree for Drifting Control IC50

Protocol 1: Standardized Control Tracking for IC50 Stability

- Control Stock Solution: Prepare a 10 mM DMSO stock of the control compound (e.g., Staurosporine for kinase assays). Aliquot into 10 µL single-use vials. Store at -20°C in a desiccated environment. Use within 6 months. Record aliquot date and freeze-thaw cycles (max: 1).

- Intermediate Dilution: On assay day, thaw one aliquot and prepare a 100 µM intermediate dilution in assay-specific buffer (e.g., PBS with 0.1% BSA to prevent adsorption). Use immediately; do not store.

- Plate Template: Include a full 10-point, 1:3 serial dilution of the control compound on every assay plate. Use the same plate map location.

- Data Tracking: Calculate the IC50 for the plate control using a 4-parameter logistic (4PL) model. Plot the log(IC50) for each plate on a Levey-Jennings style control chart. Establish warning (mean ± 2SD) and action (mean ± 3SD) limits from a minimum of 10 historical plates.

Q2: The curve fitting fails (R² < 0.8) or yields unrealistic IC50 values (e.g., >100 µM for a nM compound). How should we proceed? A: Poor curve fit usually stems from data quality or fitting parameter issues.

Diagram Title: Workflow for Troubleshooting Curve Fitting

Protocol 2: Robust 4-Parameter Logistic (4PL) Curve Fitting

- Data Normalization: Normalize raw signal (RLU, OD) to percent inhibition:

%Inhibition = 100 * ( (Median_High_Control - Data_Point) / (Median_High_Control - Median_Low_Control) ). - Initial Parameter Estimation:

- Bottom: Median of %Inhibition at the three highest concentrations.

- Top: Median of %Inhibition at the three lowest concentrations.

- Hill Slope: Start at -1.0.

- IC50: The concentration point halfway between the estimated top and bottom.

- Constrained Fitting: Use a nonlinear least-squares algorithm (e.g., Levenberg-Marquardt). Apply constraints:

Bottom = 0 ± 10,Top = 100 ± 10. Allow Hill Slope and log(IC50) to float. - Quality Thresholds: Accept fits where

R² > 0.85and the 95% confidence interval for the IC50 is within one order of magnitude.

Q3: Our untreated cell viability control (Low Control) signal is decreasing over time, compressing the assay window. What's the systematic approach? A: A declining low control indicates reduced baseline cell health or reagent failure.

Research Reagent Solutions Toolkit

| Reagent/Material | Function & Critical Consideration for IC50 Assays |

|---|---|

| Reference Control Compound (e.g., Staurosporine, Oligomycin) | Serves as a pharmacologic positive control. Must be high-purity, stored in single-use aliquots under desiccated conditions to prevent hydrolysis/degradation. |

| Cell Line with Validated Passage Range | Essential for consistency. Define a maximum passage number (e.g., p20-p35) where growth and target expression are stable. Use early-passage master banks. |

| Phenol Red-Free, Chemically Defined Medium | Eliminates background fluorescence/interference in optical assays and reduces lot-to-lot variability compared to serum-containing media. |

| Cell Viability Assay Reagent (e.g., ATP-based luminescence) | Choose a homogeneous, stable "add-mix-read" reagent. Test new lots against the current lot in parallel to ensure equivalent sensitivity and dynamic range. |

| Microplate with Ultra-Low Evaporation Lid | Critical for long-term incubations (>6 hours). Prevents edge effects and concentration shifts due to evaporation, a major cause of plate-position bias. |

| Automated Liquid Handler with Regular Calibration | Ensures precision in serial dilution and compound transfer. Calibrate tips monthly for volume accuracy and precision (CV < 5%). |

Summary of Key Quantitative Benchmarks

| Parameter | Optimal Range | Action Limit (Investigate) | Common Root Cause if Out of Range |

|---|---|---|---|

| Control IC50 (Log Scale) | Within 0.5 log of historical median | >0.8 log shift | Reagent degradation, cell drift. |

| 4PL Curve Fit R² | >0.90 | <0.85 | Poor data points, incorrect concentration range. |

| Assay Signal Window (Z'-Factor) | >0.5 | <0.4 | Low control decay, high control noise. |

| Coefficient of Variation (CV) of High/Low Controls | <10% | >15% | Cell seeding error, reagent mixing issue. |

| Cell Passage Number for Assay | p20 - p35 | >p40 | Phenotypic drift, altered target expression. |

Optimizing Control Compound Preparation, Storage, and Handling

Technical Support Center: Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: Our positive control compound (e.g., Staurosporine for kinase inhibition assays) shows a significant right-shift in IC50 values between freshly prepared and stored aliquots. What is the most likely cause and how can we prevent it? A: The primary cause is hydrolytic or oxidative degradation of the control compound in aqueous or DMSO stock solutions. Staurosporine, for instance, is susceptible to hydrolysis. To prevent this:

- Preparation: Use anhydrous, inhibitor-free DMSO for initial dissolution. Perform the dissolution rapidly in a controlled, low-humidity environment.

- Storage: Aliquot the master stock into single-use, low-protein-binding microtubes. Store under an inert gas (Argon) in sealed containers with desiccant at -80°C. Avoid freeze-thaw cycles.

- Validation: Regularly run a freshly prepared standard curve against stored aliquots to monitor potency loss.

Q2: We observe high variability in our negative control (e.g., vehicle-only) wells, leading to unreliable IC50 estimation. What steps should we take? A: High background variability often stems from improper vehicle handling or plate effects.

- Vehicle Consistency: Ensure the DMSO concentration is identical across all wells (typically ≤0.1-1.0%). Use a calibrated, positive-displacement pipette for viscous solvents.

- Plate Handling: Confirm the plate sealer is compatible with your solvents to prevent evaporation-induced edge effects. Use randomized or interleaved plate layouts to control for positional drift.

- Protocol: Include a "vehicle-only" plate in every experiment to establish a session-specific baseline.

Q3: How should we handle and prepare light-sensitive control compounds (e.g., ATCC, Forskolin)? A: Photodegradation can be a silent source of error.

- Workflow: Use amber vials and microtubes for all stock solutions. Perform liquid transfers in low-light conditions or under specific wavelength-safe light (e.g., red light for many compounds).

- Storage: Wrap aliquot containers in aluminum foil. Store as recommended for light-sensitive materials (-80°C in dark).

- Validation: Compare the activity of an aliquot exposed to ambient lab light for 1 hour versus one kept in the dark.

Q4: What is the recommended maximum storage time for DMSO stock solutions of common but unstable controls at -80°C? A: While -80°C storage slows degradation, it does not halt it entirely. Adhere to empirically validated shelf lives. General guidelines from recent literature are summarized below:

Table 1: Recommended Storage Life for Common Control Compounds in Anhydrous DMSO at -80°C

| Compound | Common Use | Max Recommended Storage | Key Degradation Mode |

|---|---|---|---|

| Staurosporine | Kinase inhibitor (positive control) | 6 months | Hydrolysis |

| Cycloheximide | Protein synthesis inhibitor | 12 months | Oxidation |

| Forskolin | Adenylate cyclase activator | 3 months | Photodegradation, Oxidation |

| ATCC (Actinomycin D) | Transcription inhibitor | 6 months | Photodegradation |

| MG-132 | Proteasome inhibitor | 3 months | Hydrolysis |

Experimental Protocol: Validating Control Compound Stability for IC50 Assays

Objective: To determine the practical shelf-life of a control compound stock solution and its impact on IC50 estimation.

Materials:

- Test control compound (e.g., Staurosporine)

- Anhydrous, inhibitor-free DMSO

- Target assay kit/reagents (e.g., kinase activity assay)

- Low-protein-binding microtubes (amber if light-sensitive)

Methodology:

- Master Stock Preparation: Dissolve the compound in anhydrous DMSO to a concentration 1000X the final highest test concentration. Vortex thoroughly for 1-2 minutes.

- Aliquotting: Immediately aliquot 10 µL into 20 separate pre-chilled, labeled microtubes.

- Storage: Place 18 aliquots at -80°C under inert gas. Keep 2 aliquots at +4°C and -20°C for comparison.

- Time-Course Testing: At time zero (T0), and at monthly intervals (T1, T2, T3...T6), retrieve one aliquot from -80°C. Thaw rapidly in a desiccator at room temperature.

- IC50 Determination: In your target assay, prepare a serial dilution from the thawed aliquot and run a full dose-response curve alongside a freshly prepared standard from powder. Run in triplicate.

- Data Analysis: Fit the dose-response data to a 4-parameter logistic model. Calculate the IC50 for the stored aliquot (IC50stored) and the fresh standard (IC50fresh).

- Potency Loss Calculation: % Potency Remaining = (IC50fresh / IC50stored) * 100%. A loss of >20% potency typically indicates the aliquot should not be used for critical IC50 estimation.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Control Compound Handling

| Item | Function & Rationale |

|---|---|

| Anhydrous, Inhibitor-Free DMSO | Primary solvent. Anhydrous state minimizes hydrolytic degradation. "Inhibitor-free" grade prevents confounding bioactivity. |

| Low-Protein-Binding Microtubes | Prevents compound adsorption to tube walls, ensuring accurate concentration transfer. |

| Argon Gas Canister | Creates an inert atmosphere when flushing storage vials, drastically reducing oxidative degradation. |

| Desiccant (e.g., silica gel) | Maintains a low-humidity environment in storage containers, protecting against hydrolysis. |

| Positive-Displacement Pipettes | Provides highly accurate and reproducible transfer of viscous solvents like DMSO, critical for vehicle consistency. |

| Plate Sealer (Solvent-Resistant) | Prevents evaporation and cross-contamination of compounds in assay plates, reducing edge effects. |

Visualization: Control Compound Stability Workflow

Diagram Title: Stability Validation Workflow for IC50 Control Compounds

Visualization: Key Degradation Pathways for Unstable Controls

Diagram Title: Primary Degradation Pathways Affecting Control Compound Stability

Protocol Adjustments for Cell-Based vs. Biochemical Assays

Technical Support Center: Troubleshooting Guides & FAQs

FAQ: My IC50 values from cell-based assays are highly variable compared to my biochemical assay results. What could be the cause? Answer: This is a common challenge when moving from a purified system to a cellular context. Key factors include:

- Cellular Permeability: The compound may not efficiently enter the cells.

- Off-Target Effects & Pathway Crosstalk: Cellular signaling networks can modulate the target's activity.

- Protein Turnover & Expression Levels: Target abundance is dynamic in cells but fixed in biochemical assays.

- Unstable Control Signals: Viability or reporter controls can drift, skewing dose-response curves. Always run concurrent, plate-based controls for normalization.

Troubleshooting Guide: High Background or Poor Signal-to-Noise in Cell-Based Viability Assays. Q1: My positive control (100% inhibition) shows high residual signal. A1: Confirm the cytotoxic agent (e.g., staurosporine) is fresh, properly diluted, and incubated for an adequate duration (often 48-72 hours). Check for assay reagent interference.

Q2: My negative control (0% inhibition, DMSO-only) shows low signal. A2: This indicates baseline cell death or poor health. Ensure cells are in log-phase growth, not over-confluent, and that the DMSO concentration is non-toxic (typically ≤0.5%). Optimize seeding density.

FAQ: How should I adjust compound incubation times between assay types? Answer: Biochemical assays often use short incubations (minutes to 1-2 hours) at enzyme equilibrium. Cell-based assays require longer incubations (24-72 hours) to allow for compound uptake, target engagement, and downstream phenotypic effects (e.g., cell death). This must be empirically determined.

Troubleshooting Guide: Biochemical Assay Artifacts. Q1: My enzyme inhibition curve shows a "hook effect" at high compound concentrations. A1: This suggests compound aggregation, a common pitfall. Check for precipitation. Include a non-ionic detergent (e.g., 0.01% Triton X-100) in the assay buffer and test dilution from a fresh stock.

Q2: The assay shows high coefficient of variation (CV) between replicates. A2: Ensure the enzyme preparation is homogeneous and stable. Pre-incubate enzyme with compound before adding substrate to establish steady-state kinetics. Verify pipetting accuracy for small volumes.

Quantitative Data Summary: Key Parameter Adjustments

Table 1: Typical Protocol Parameter Ranges for IC50 Estimation

| Parameter | Biochemical Assay (Kinase Example) | Cell-Based Assay (Viability Example) | Rationale for Adjustment |

|---|---|---|---|

| Incubation Time | 30 - 120 minutes | 48 - 72 hours | Time for cellular uptake, target modulation, and phenotypic outcome. |

| Compound [DMSO] | Up to 1% (v/v) | ≤ 0.5% (v/v) | Higher DMSO is often cytotoxic in long-term cell assays. |

| Control for Normalization | No-enzyme control (0% signal) | Untreated cells (100% viability) & Cytotoxin-treated (0% viability) | Cell assays require dual-point normalization to account for unstable baselines. |

| Reagent Addition Order | Enzyme + Compound → Substrate | Compound → Pre-incubate → Assay Reagent | Cells require compound pre-treatment before endpoint measurement. |

| Assay Temperature | Room Temp or 25°C | 37°C, 5% CO₂ | Maintains physiological relevance for cell health and signaling. |

| Key Artifact | Compound aggregation | Cellular efflux pumps, metabolism | Mitigate with detergent (biochemical) or efflux inhibitor (cell-based). |

Experimental Protocols

Protocol 1: Cell-Based Viability Assay (ATP Quantification) for IC50

- Cell Seeding: Seed cells in 96-well tissue culture plates at an optimized density (e.g., 2,000-5,000 cells/well) in 90 μL of complete growth medium. Incubate overnight (37°C, 5% CO₂).

- Compound Treatment: Prepare 10X compound dilutions in DMSO, then in medium (final [DMSO] = 0.5%). Add 10 μL of each dilution to triplicate wells. Include vehicle (DMSO) control wells (0% inhibition) and a control for 100% inhibition (e.g., 1-10 μM staurosporine).

- Incubation: Incubate plate for 48-72 hours.

- ATP Detection: Equilibrate plate to room temp. Add 50 μL of CellTiter-Glo 2.0 reagent. Shake for 2 minutes, incubate for 10 minutes in the dark.

- Measurement: Record luminescence on a plate reader.

- Data Analysis: Normalize: % Viability = (RLU_sample - RLU_100%_Inhibition) / (RLU_0%_Inhibition - RLU_100%_Inhibition) x 100. Fit normalized data to a 4-parameter logistic model for IC50.

Protocol 2: Biochemical Kinase Inhibition Assay (ADP-Glo) for IC50

- Reaction Setup: In a half-area 96-well plate, add 2.5 μL of compound in DMSO (or control).

- Enzyme Addition: Add 5 μL of kinase in assay buffer. Shake briefly.

- Pre-incubation: Incubate at room temp for 15 minutes.

- Initiate Reaction: Add 2.5 μL of ATP/substrate mix to start reaction. Final typical conditions: [ATP] = KM, ATP.

- Reaction Incubation: Incubate at 25°C for 60 minutes.

- Stop & Detect: Add 10 μL of ADP-Glo Reagent to stop reaction and deplete residual ATP. Incubate 40 min. Add 20 μL of Kinase Detection Reagent to convert ADP to ATP and detect via luciferase. Incubate 30-60 min.

- Measurement: Record luminescence.

- Data Analysis: Normalize: % Inhibition = (1 - (RLU_sample - RLU_no_enzyme) / (RLU_DMSO_control - RLU_no_enzyme)) x 100. Fit to a 4-parameter logistic model for IC50.

Signaling Pathways & Experimental Workflows

Compound Action to Assay Readout in Cells

IC50 Assay Selection and Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents & Materials for Comparative IC50 Studies

| Item | Function & Importance | Example Product/Brand |

|---|---|---|

| ATP Quantification Kit | Measures cellular ATP as a proxy for viability; gold standard for cytotoxicity. | CellTiter-Glo 2.0 |

| Biochemical Kinase Kit | Homogeneous, coupled assay to measure kinase activity via ADP detection. | ADP-Glo Kinase Assay |

| Validated Inhibitor Control | Pharmacological tool to define 100% inhibition baseline in cell assays. | Staurosporine |

| Efflux Transporter Inhibitor | Used in cell assays to mitigate false negatives from compound efflux. | Verapamil (P-gp inhibitor) |

| Detergent (Non-ionic) | Prevents compound aggregation in biochemical assays, reducing artifacts. | Triton X-100 |

| Low-Binding Microplates/Tips | Minimizes compound loss due to adsorption, critical for hydrophobic molecules. | Polypropylene plates, LoBind tips |

| Stable, Passage-Low Cell Line | Ensures consistent response across experiments; critical for reproducibility. | Early-passage, mycoplasma-free stocks |

| 4-Parameter Logistic Curve Fit Software | Industry standard for robust IC50 calculation from dose-response data. | GraphPad Prism, R (drc package) |

Mitigating Edge Effects, Evaporation, and Plate Reader Artifacts

Troubleshooting Guides & FAQs

FAQ 1: How do I identify if my IC50 data is compromised by edge effects?