Strategic Timing: Mastering Optimal Sampling for Accurate Enzyme Kinetic Analysis in Drug Discovery

This article provides a comprehensive guide for researchers and drug development professionals on designing optimal sampling strategies for enzyme kinetic studies.

Strategic Timing: Mastering Optimal Sampling for Accurate Enzyme Kinetic Analysis in Drug Discovery

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on designing optimal sampling strategies for enzyme kinetic studies. It covers the foundational principles of why sampling time is a critical experimental variable, explores modern methodological frameworks like Optimal Experimental Design (OED) and Fisher information matrix analysis [citation:2][citation:3], and presents practical algorithms for determining sample points. The content addresses common troubleshooting scenarios, such as deviations from Michaelis-Menten assumptions and handling parameter uncertainty [citation:8]. Finally, it validates these approaches by comparing optimized designs against standard methods, demonstrating significant improvements in parameter precision (e.g., reducing estimation error variance by up to 40% in fed-batch systems) and their impact on predicting critical drug metabolism parameters like intrinsic clearance [citation:1][citation:3][citation:8].

The Critical Why: Understanding How Sampling Time Dictates Enzyme Kinetic Data Quality

In the field of drug discovery, the accurate assessment of metabolic stability via enzyme kinetic parameters (Vmax, Km, and intrinsic clearance, CLint) is a critical, rate-limiting step. Traditionally, experimental designs for these studies have been based on empirical or arbitrary approaches, such as using a single starting concentration (e.g., 1 µM) and fixed time points, under the assumption of linear pharmacokinetics [1]. This conventional method can lead to significant uncertainty in parameter estimates, especially when substrate concentrations approach or exceed the Km, violating the linearity assumption.

Recent research demonstrates that moving from these arbitrary points to an Optimal Experimental Design (OED) paradigm substantially improves data quality. By strategically optimizing two key variables—the initial substrate concentration (C0) and the sampling time points—researchers can minimize the statistical uncertainty (standard error) of the estimated parameters [1]. Implementing an OED approach is shown to generate better results for 99% of compounds in CLint estimation and enables high-quality estimates of both Vmax and Km for a significant portion of screened compounds [1]. This technical support center is designed to help researchers implement these optimal strategies, troubleshoot common experimental issues, and leverage advanced computational tools to enhance the efficiency and reliability of enzyme kinetic studies.

Troubleshooting Guide: Common Issues in Enzyme Kinetic Assays

Problem 1: High Variability or Poor Model Fit in Parameter Estimates

- Symptoms: Wide confidence intervals for Vmax and Km, poor goodness-of-fit statistics (e.g., low R²), failure of the model to converge during nonlinear regression.

- Potential Causes & Solutions:

- Sub-Optimal Sampling Design: Data points may be clustered or fail to inform the critical curvilinear region of the Michaelis-Menten plot.

- Incorrect Assumption of Linear Kinetics: Using a monoexponential decay model when substrate depletion is not first-order.

- Solution: Visually inspect the substrate depletion curve. If it is not log-linear, fit the full Michaelis-Menten model. A standard design often fails here, whereas an optimal design is robust for both linear and nonlinear conditions [1].

- Insufficient Analytical Sensitivity: High background noise or poor detection limits at low substrate concentrations.

- Solution: Validate the lower limit of quantification (LLOQ) of your analytical method (e.g., LC-MS/MS). Ensure sample points are not taken at concentrations near or below the LLOQ.

Problem 2: Inconsistent Results Between Experimental Replicates

- Symptoms: Significant drift in estimated CLint between runs performed on different days or with different reagent batches.

- Potential Causes & Solutions:

- Enzyme Source Instability: Loss of enzymatic activity in microsomal or recombinant enzyme preparations.

- Solution: Aliquot and store enzyme sources at ≤ -80°C. Perform a positive control (e.g., a probe substrate with well-established kinetics) with every experimental batch to monitor activity.

- Cofactor Depletion or Degradation: NADPH concentration falls below sustaining levels, or the regeneration system fails.

- Solution: Prepare fresh NADPH stock solution for each experiment. Include a control to verify the function of the regeneration system (e.g., glucose-6-phosphate dehydrogenase).

- Nonspecific Binding: Test compound binds to labware (plates, tips) or incubation components, reducing free concentration.

- Solution: Assess nonspecific binding in your system. Use low-binding labware and consider adding a non-interacting protein like bovine serum albumin (BSA) to incubation buffers to minimize binding [1].

- Enzyme Source Instability: Loss of enzymatic activity in microsomal or recombinant enzyme preparations.

Problem 3: Computational Prediction Tools Yield Inaccurate Kinetic Parameters

- Symptoms: Large discrepancies between in silico predictions (e.g., for kcat or Km) and experimentally measured values, especially for novel enzyme-substrate pairs.

- Potential Causes & Solutions:

- Tool Used Lacks a Unified Framework: Many models predict only kcat or Km independently, leading to inaccurate derived values for catalytic efficiency (kcat/Km) [2].

- Solution: Employ a unified prediction framework like UniKP, which uses pretrained language models on protein sequences and substrate structures to simultaneously predict kcat, Km, and kcat/Km with higher correlation to experimental data [2].

- Environmental Factors Ignored: Predictions do not account for the pH or temperature of your specific assay conditions.

- Solution: If available, use tools with environmental factor modules (e.g., EF-UniKP) or ensure your experimental conditions match the training conditions of the predictive model [2].

- Out-of-Domain Prediction: The enzyme-substrate pair is highly dissimilar to any in the model's training set.

- Solution: Treat computational predictions as initial guides. Prioritize such compounds for empirical screening using an optimal experimental design to obtain reliable data.

- Tool Used Lacks a Unified Framework: Many models predict only kcat or Km independently, leading to inaccurate derived values for catalytic efficiency (kcat/Km) [2].

Frequently Asked Questions (FAQs)

General & Experimental Design

- Q: Why is a standard design with C0=1 µM and fixed time points often insufficient?

- A: This standard design (STD-D) assumes substrate concentration is always much lower than Km, leading to first-order (linear) kinetics. When this assumption is false, the STD-D provides poor information to estimate the individual parameters Vmax and Km, leading to high uncertainty. An optimal design strategically selects C0 and sample times to minimize this uncertainty regardless of whether kinetics are linear or nonlinear [1].

Q: What is the core principle behind Optimal Experimental Design (OED) for kinetics?

- A: OED uses statistical methods (like a penalized expectation of determinant, ED-optimal, design) to pre-define the experimental settings (C0, time points) that will maximize the information content of the resulting data. The goal is to minimize the expected standard error of the parameter estimates (Vmax, Km) before any experiment is run [1].

Q: I have limited resources. Can optimal design reduce my experimental costs?

- A: Yes. A key advantage of OED is efficiency. A study demonstrated that a pragmatic optimal design using only 15 samples per compound could outperform a standard design, meaning you can obtain higher-quality data without increasing sample number [1].

Data Analysis & Interpretation

- Q: When should I use the Michaelis-Menten model versus a simple monoexponential decay model?

- A: Always start by fitting the full Michaelis-Menten model. The monoexponential model is a special case where C0 << Km. If your estimated Km is significantly greater than your C0 (e.g., >10x), then the simpler model may suffice. Using an optimal design makes this decision clearer, as it provides good estimates for both models [1].

- Q: What are acceptable error thresholds for high-quality enzyme kinetic data?

Computational Tools

- Q: How can computational predictions assist my wet-lab experiments?

- A: Tools like UniKP can prioritize which enzyme-substrate pairs to test experimentally, propose promising enzyme candidates from sequence databases, and guide directed evolution campaigns by predicting the kinetic impact of mutations [2]. They serve as a force multiplier for experimental programs.

- Q: My compound is novel and not in any database. Can I still use prediction tools?

- A: Yes, but with caution. Unified frameworks like UniKP encode substrate structures (via SMILES strings) and enzyme sequences, so they can make predictions for novel combinations based on learned chemical and biological patterns. However, predictions for highly unique structures are less reliable and must be validated empirically [2].

Key Experimental Protocols

Protocol 1: Implementing an Optimal Design for Metabolic Stability Screening

This protocol outlines the steps to design and execute a kinetic assay using principles of Optimal Experimental Design (OED) [1].

Objective: To determine the intrinsic clearance (CLint) and, where possible, Vmax and Km of a test compound using a pre-optimized sampling strategy.

Materials: (Refer to "The Scientist's Toolkit" table below). Software: Optimal design software (e.g., PopED).

Procedure:

- Prior Parameter Estimation: Use literature, in silico tools (e.g., UniKP [2]), or preliminary data to define a plausible range for Vmax and Km (or CLint) for your enzyme system.

- Design Optimization:

- Input the parameter ranges and experimental constraints (e.g., max incubation time = 40 min, total samples = 15, C0 range = 0.01-100 µM) into the OED software [1].

- Run the optimization algorithm (e.g., ED-optimal design) to obtain the recommended initial concentration(s) (C0) and specific sampling time points.

- Incubation Setup:

- Prepare incubation mixtures containing the enzyme source (e.g., human liver microsomes), cofactor system (NADPH-regenerating), and buffer.

- Pre-incubate for 5 minutes at 37°C. Initiate reactions by adding the test compound at the optimized C0. Run reactions in triplicate.

- Include control incubations without cofactors (to assess non-enzymatic loss) and without enzyme (for time-zero).

- Sample Collection:

- At each pre-defined optimal time point, withdraw an aliquot and immediately quench the reaction (e.g., with cold acetonitrile containing an internal standard).

- Sample Analysis & Data Processing:

- Analyze quenched samples using a validated quantitative method (e.g., LC-MS/MS).

- Calculate the remaining substrate concentration at each time point.

- Kinetic Analysis:

- Fit the substrate depletion data (concentration vs. time) to the Michaelis-Menten equation using nonlinear regression software.

- Report estimates for Vmax, Km, and CLint (=Vmax/Km) with confidence intervals. Compare the fit to a monoexponential model if C0 is suspected to be very low relative to Km.

Protocol 2: Validating a Unified Computational Prediction (UniKP) for Enzyme Engineering

This protocol describes how to use the UniKP framework to predict kinetic parameters and guide experimental validation [2].

Objective: To identify enzyme variants with improved catalytic efficiency (kcat/Km) using computational predictions.

Materials: UniKP web server or standalone software; molecular biology tools for site-directed mutagenesis; standard kinetic assay reagents.

Procedure:

- Input Preparation:

- Obtain the amino acid sequence (FASTA format) of your wild-type enzyme and the SMILES string of your target substrate.

- Parameter Prediction:

- Input the sequence and SMILES into the UniKP framework.

- Run the model to obtain predicted values for kcat, Km, and kcat/Km for the wild-type enzyme.

- In Silico Mutagenesis & Screening:

- Generate a library of mutant enzyme sequences (e.g., single-point mutations at active site residues).

- Use UniKP to predict kinetic parameters for each mutant.

- Rank mutants based on predicted improvement in kcat/Km or other desired parameters.

- Experimental Validation:

- Select the top 5-10 predicted mutants for empirical testing.

- Express and purify the wild-type and mutant enzymes.

- Perform detailed enzyme kinetic assays (using principles from Protocol 1) to determine experimental kcat and Km.

- Analysis and Iteration:

- Compare predicted vs. experimental parameters to assess UniKP's accuracy for your system.

- Use the experimental data to potentially refine the computational model or select leads for further engineering rounds.

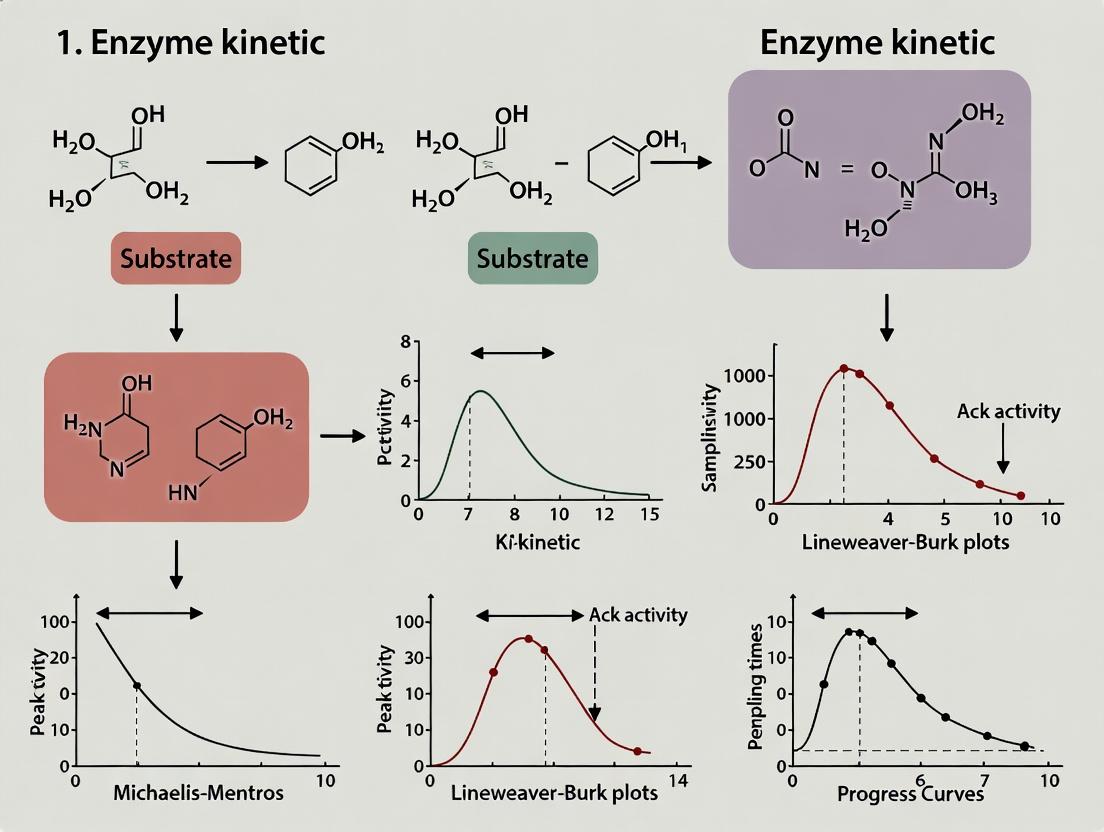

Visualizing Workflows and Relationships

Optimal Experimental Design Workflow

Unified Kinetic Prediction (UniKP) Framework

The Scientist's Toolkit

The following table details essential reagents, software, and materials required for conducting optimal enzyme kinetic studies.

| Item | Category | Function & Application |

|---|---|---|

| Hepatic Microsomes (Human/Preclinical) | Biological Reagent | Source of cytochrome P450 and other drug-metabolizing enzymes for in vitro metabolic stability assays [1]. |

| NADPH Regenerating System | Biochemical Reagent | Supplies continuous reducing equivalents (NADPH) required for oxidative metabolic reactions. A stable concentration is critical for kinetic consistency. |

| PopED (Software) | Computational Tool | A software package for optimal experimental design used to optimize sampling times and initial concentrations for parameter estimation [1]. |

| UniKP Framework | Computational Tool | A unified machine learning framework for predicting enzyme kinetic parameters (kcat, Km, kcat/Km) from protein sequence and substrate structure [2]. |

| LC-MS/MS System | Analytical Instrument | The gold-standard method for the sensitive, specific, and quantitative measurement of substrate depletion in complex biological matrices. |

| Low-Binding Microplates & Tips | Labware | Minimizes nonspecific binding of lipophilic test compounds, ensuring the accurate measurement of free substrate concentration [1]. |

Performance Comparison: Standard vs. Optimal Design

The quantitative benefits of adopting an optimal experimental design strategy are summarized in the table below, based on simulation studies [1].

| Design Type | Key Characteristics | Performance Metrics (Simulation Results) |

|---|---|---|

| Standard Design (STD-D) | Single C0 (e.g., 1 µM), arbitrary fixed time points, assumes linear (first-order) kinetics. | Served as the baseline for comparison. Often inadequate for reliable Vmax/Km estimation when C0 is not << Km. |

| Pragmatic Optimal Design (OD) | C0 optimized within a range (0.01-100 µM), sample times optimized up to 40 min, limited to 15 total samples. | CLint Estimation: Better result (lower relative standard error) for 99% of compounds. Vmax/Km Estimation: Provided high-quality estimates (RMSE < 30%) for 26% of compounds. |

| General Optimal Design (G-OD) | Compound-specific optimization of C0 and time points for each unique Vmax/Km pair. | Represents the theoretical performance ceiling. Used to generate the parameter distributions for creating the pragmatic OD. |

- [1] Sjögren et al. detail the methodology and superior outcomes of using a penalized ED-optimal design for enzyme kinetic assessment in drug discovery screening.

- [2] The developers of UniKP present a unified deep learning framework that significantly improves the prediction of kcat, Km, and kcat/Km from sequence and structure data.

Thesis Context: This technical support guide is framed within a broader research thesis advocating for optimized, information-rich sampling strategies in enzyme kinetic studies. It argues that moving beyond traditional initial velocity assays to analyze complete reaction progress curves provides more robust parameter estimation, enables the detection of complex kinetics and assay artifacts, and ultimately leads to more reliable data for drug development and biochemical research [3] [4].

Frequently Asked Questions (FAQs)

Q1: Why should I analyze the entire progress curve instead of just measuring the initial velocity? A1: The initial velocity is just a single, often approximated, point on a rich kinetic profile. Analyzing the complete progress curve leverages all the data from a single experiment, reducing time and reagent costs [3]. More importantly, it allows for direct detection of common assay failures (like substrate exhaustion) that can lead to grossly inaccurate results [5], and provides more robust parameter estimates, especially when enzyme concentration is not negligible compared to substrate or KM [4].

Q2: What are the most common pitfalls when performing progress curve analysis? A2: The two most critical pitfalls are:

- Substrate Depletion: Using a starting substrate concentration (

S0) that is too low relative to enzyme activity leads to premature substrate exhaustion. This causes a progress curve that plateaus early and can be misinterpreted as low enzyme activity, a phenomenon analogous to the prozone effect in immunoassays [5]. - Poor Parameter Identifiability: Attempting to extract too many kinetic parameters (e.g.,

k1,k-1,k2) from a progress curve obtained at a single substrate concentration. The data may fit well, but the individual parameters are not uniquely determined and can vary over orders of magnitude [6]. Reliable estimation requires experiments at multiple starting substrate concentrations (S0) [6] [4].

Q3: How do I choose the right substrate concentrations and sampling times for a progress curve experiment?

A3: An optimal experimental design (OD) is superior to a standard one. Research shows that a design using multiple starting concentrations (S0) with late sampling time points is highly effective. For example, a pragmatic OD using 15 samples across various S0 values (e.g., from 0.01 to 100 µM) over 40 minutes provided better parameter estimates than a standard single-concentration design for the majority of compounds tested [7] [8]. The ideal S0 should bracket the expected KM value [4].

Q4: My progress curve is not sigmoidal; it shows a sharp "knee" and then a flat line. What does this mean? A4: This shape is a classic indicator of substrate exhaustion or "substrate depletion" [5]. The enzyme in the sample is so active that it consumes all the substrate very early in the assay, during what should be the linear initial velocity phase. The reported activity will be falsely low. The solution is to significantly dilute the sample and repeat the assay [5].

Q5: When using software (e.g., DynaFit, FITSIM) to fit progress curves, why do my estimated rate constants seem unstable or unrealistic?

A5: This is likely due to the identifiability problem mentioned in A2. The software may converge on a good fit to the data with a mathematically valid but biologically meaningless combination of elementary rate constants. You should constrain the analysis to fitting the macro-constants KM and Vmax (or kcat), which are more reliably determined from progress curves. Using data from multiple S0 is essential for reliable KM estimation [6].

Q6: Is the classic Michaelis-Menten equation sufficient for analyzing all progress curves?

A6: No. The classic equation derived from the standard quasi-steady-state assumption (sQSSA) is only valid when total enzyme concentration ([E]T) is much lower than KM + S0 [4]. In many real-world scenarios, especially in drug discovery with microsomal preparations or cellular contexts, this condition is violated. For accurate fitting under these conditions, you should use an equation derived from the total quasi-steady-state approximation (tQSSA), which remains accurate even when [E]T is high [4].

Troubleshooting Common Experimental Issues

| Problem Observed | Likely Cause | Diagnostic Check | Recommended Action |

|---|---|---|---|

| Falsely low activity reading in a clinical/high-activity sample. | Substrate exhaustion. The progress curve plateaus very early [5]. | Inspect the stored progress curve for a sharp bend and early plateau instead of a prolonged linear phase [5]. | Perform a serial dilution of the sample (e.g., 1:100) and re-assay [5]. |

Poor reproducibility and high uncertainty in fitted KM and Vmax. |

Sub-optimal experimental design (e.g., single S0, poor time coverage) [7]. |

Check if sampling times are clustered or if only one S0 was used. |

Implement an Optimal Design (OD): Use 3-5 different S0 values spanning below and above expected KM, with samples taken at early, mid, and late time points [7] [8]. |

| Software fitting fails or parameters are unrealistic. | Poor initial parameter guesses or model mismatch (using sQSSA when tQSSA is needed) [3] [4]. | Plot the model prediction with your initial guesses against the data. Switch from sQSSA to tQSSA-based fitting if [E]T is not very low [4]. |

Use a numerical method with spline interpolation, which is less dependent on initial guesses [3]. Use a Bayesian fitting approach with the tQ model [4]. |

| Need to discriminate between two rival kinetic mechanisms (e.g., 1-substrate vs. 2-substrate). | Standard experimental data is insufficiently informative [9]. | Simulate progress curves for both models using initial parameter estimates. | Use model discrimination design: Calculate experimental conditions (e.g., specific S0 combinations) that maximize the difference between the two models' predicted curves [9]. |

The following table summarizes key findings from studies comparing Optimal Experimental Design (ODA) with Standard or more resource-intensive methods [7] [8].

| Comparison Metric | Standard/Single-Point Design | Optimal Design (ODA) with Multiple S0 |

Implication for Research |

|---|---|---|---|

| General Performance | Suboptimal for parameter estimation; high risk of error if linearity assumption is violated [7] [8]. | Superior output in 99% of compounds for CLint precision; equal/better RMSE in 78% of compounds [7]. | ODA provides more reliable parameters with the same or fewer data points. |

| Parameter Agreement | N/A (reference method) | >90% of CLint estimates within 2-fold of reference; >80% of Vmax/Km within/near 2-fold agreement [8]. | ODA is a valid, resource-efficient alternative to comprehensive methods like MDCM. |

| Key Constraints | Often uses a single substrate concentration (e.g., 1 µM) and limited time points [7]. | Pragmatic design: Up to 15 samples, incubation time ≤40 min, S0 from 0.01–100 µM [7]. |

Robust kinetics can be obtained under practical screening constraints. |

| High-Quality Estimates | Not typically designed to estimate both Vmax and Km reliably. | Enabled high-quality estimates (RMSE <30%) of both Vmax and Km for 26% of investigated compounds [7]. | Facilitates assessment of non-linear metabolism risk in drug discovery. |

Detailed Experimental Protocols

Protocol 1: Optimal Design Approach (ODA) for Microsomal Stability

This protocol is adapted from studies evaluating enzyme kinetics in drug discovery using human liver microsomes (HLM) [8].

Objective: Estimate intrinsic clearance (CLint), Vmax, and Km for a test compound using a limited number of samples.

Materials:

- Test compound stock solution in DMSO.

- Human Liver Microsomes (HLM) pool.

- NADPH regeneration system.

- Phosphate buffer (e.g., 0.1 M, pH 7.4).

- Stopping solution (e.g., acetonitrile with internal standard).

- LC-MS/MS system for analysis.

Procedure:

- Incubation Setup: Prepare incubation mixtures containing HLM (e.g., 0.5 mg/mL protein) and the NADPH system in buffer. Pre-warm for 5 minutes.

- Multiple Starting Concentrations: Initiate reactions by adding the test compound at 3-5 different starting concentrations (

S0). A recommended range is from 0.1x to 10x the anticipated Km (e.g., 0.5, 2, 10, 50 µM) [7] [8]. - Time-Point Sampling: For each

S0, remove aliquots at multiple time points (e.g., 5, 10, 20, 40 minutes). The total number of samples should not exceed practical limits (e.g., 15) [7]. - Reaction Termination: Immediately transfer each aliquot to a pre-chilled stopping solution to quench the metabolic reaction.

- Sample Analysis: Centrifuge samples and analyze the supernatant by LC-MS/MS to determine the remaining substrate concentration at each time point.

- Data Analysis: Fit the depletion data (substrate concentration vs. time for each

S0) simultaneously to the Michaelis-Menten integrated equation or a tQSSA model using non-linear regression software to estimate CLint, Vmax, and Km [8] [4].

Protocol 2: Bayesian Progress Curve Analysis Using the tQSSA Model

This protocol uses a more robust mathematical model to avoid bias when enzyme concentration is high [4].

Objective: Accurately estimate kcat and KM from a progress curve, especially when [E]T is not negligible.

Materials:

- Purified enzyme and substrate.

- Appropriate assay buffer and detection system (e.g., spectrophotometer, fluorometer).

- Computational software (e.g., provided package from [4], or general tools like R/Python with ODE solvers).

Procedure:

- Reaction Monitoring: Conduct a progress curve assay, recording product formation (e.g., absorbance) over time. It is advantageous to run experiments at two different enzyme concentrations (low and high) to improve identifiability [4].

- Model Selection: Use the tQSSA model (Equation 2 in [4]) instead of the classic Michaelis-Menten (sQSSA) equation for data fitting. This is crucial if

[E]T / (KM + S0)is not much less than 1. - Bayesian Inference: Implement a Bayesian fitting procedure. This involves:

- Defining prior distributions for kcat and KM (often broad, uninformative priors).

- Using Markov Chain Monte Carlo (MCMC) sampling to compute the posterior distribution of the parameters given the progress curve data.

- Optimal Design: Analyze scatter plots of the posterior distributions. If parameters are poorly identified (high correlation), design the next experiment by choosing an

S0that lies in the region of greatest uncertainty, often around the estimated KM value [4]. - Validation: Pool data from multiple experiments (different

[E]TorS0) and refit using the tQ model to obtain final, precise estimates of kcat and KM.

Visualizations for Experimental Workflow & Analysis

Diagram 1: Progress Curve Analysis Workflow (68 chars)

Diagram 2: Optimal vs. Suboptimal Sampling Design (70 chars)

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Primary Function | Key Consideration / Example |

|---|---|---|

| Human Liver Microsomes (HLM) | In vitro system containing human cytochrome P450 enzymes and other drug-metabolizing enzymes for hepatic clearance studies [8]. | Pooled from multiple donors to represent average metabolic activity. |

| NADPH Regeneration System | Supplies constant reducing equivalents (NADPH) required for oxidative metabolism by P450 enzymes. | Essential for maintaining metabolic activity throughout incubation. |

| LC-MS/MS System | Gold-standard analytical platform for quantifying substrate depletion or product formation in complex matrices with high sensitivity and specificity [8]. | Allows for direct measurement of substrate concentration over time. |

| N-Acetyl Cysteine (NAC) | Reagent additive to reactivate sulfhydryl groups in enzymes like creatine kinase, preventing oxidative loss of activity [5]. | Critical for accurate measurement of sulfhydryl-dependent enzymes. |

| Adenosine Monophosphate (AMP) | Inhibitor of contaminating adenylate kinase activity in clinical samples, which can interfere with target enzyme assays [5]. | Improves assay specificity. |

| Reference Compounds | Well-characterized substrates for specific enzymes (e.g., Midazolam for CYP3A4, Diclofenac for CYP2C9) [8]. | Used for system suitability testing and validation of assay conditions. |

| Computational Fitting Software | Tools for non-linear regression of progress curve data (e.g., DynaFit, custom scripts for tQSSA/Bayesian analysis [6] [4]). | Necessary for extracting kinetic parameters from time-course data. |

Technical Support Center: Enzyme Kinetic Studies

This technical support center provides troubleshooting guidance and best practices for researchers determining enzyme kinetic parameters (Vmax, Km, CLint). Accurate estimation of these parameters is foundational for drug metabolism studies, enzyme characterization, and pharmacokinetic modeling. A core thesis in this field posits that the strategic optimization of sampling times and data collection methods is not merely operational but fundamental to obtaining reliable, reproducible kinetic data [10]. The following guides address common experimental challenges.

Troubleshooting Guide 1: Inconsistent or Low-Precision Km and Vmax Estimates

- Problem: Fitted values for Km and Vmax vary widely between replicates or experimental runs.

- Solution & Best Practice:

- Move Beyond Initial Rates: Consider using full progress curve analysis or the Multiple Depletion Curves Method (MDCM). These methods use all data points from a reaction time course, improving statistical power and parameter precision [11].

- Focus on the Area of Maximum Curvature: When analyzing progress curves, fitting the entire curve can give poor Km estimates if the plateau region dominates the fit. Use algorithms (e.g., iFIT) or manually select data points primarily from the region of maximum curvature on the progress curve, as this area contains the most information about Km [11].

- Control Assay Conditions Rigorously: Ensure precise temperature control, as a 1°C change can alter enzyme activity by 4-8% [12]. Maintain optimal, buffered pH throughout the experiment.

- Apply the Correct Model: For depletion assays (e.g., metabolic clearance), implement the MDCM, which models substrate loss over time from multiple starting concentrations and is robust for estimating Vmax, Km, and CLint [13].

Troubleshooting Guide 2: Underestimating Intrinsic Clearance (CLint) in Metabolic Stability Assays

- Problem: Estimated CLint from in vitro half-life (t½) methods is lower than expected or inconsistent with in vivo data.

- Solution & Best Practice:

- Avoid the "In Vitro t½ Method" for Non-First-Order Kinetics: The t½ method assumes substrate concentration is much lower than Km (first-order conditions). This assumption is often violated, leading to underestimation of CLint [13].

- Adopt the Multiple Depletion Curves Method (MDCM): This method accurately estimates CLint across a wide range of substrate concentrations and turnover rates without requiring the first-order assumption. It also allows for correction of enzyme activity loss during incubation [13] [14].

- Sample Adequately Across the Depletion Curve: Ensure your sampling schedule captures the full shape of the substrate depletion curve, especially the early, rapid phase of depletion. Monte Carlo simulations confirm the robustness of MDCM with varied sampling [15].

Troubleshooting Guide 3: Choosing Optimal Sampling Time Points

- Problem: Uncertainty in when to sample reaction mixtures or plasma to derive accurate kinetic or pharmacokinetic parameters.

- Solution & Best Practice:

- For Enzyme Progress Curves: Sample densely during the initial curved portion of the reaction. Sparse early sampling loses critical information on velocity.

- For In Vitro Depletion Assays (MDCM): Sample from each starting concentration at multiple time points until at least 50-80% substrate depletion is achieved to define the curve [13].

- For Pharmacokinetic (PK) AUC Estimation: Model-based sampling is key. For example, to estimate vancomycin AUC after a first dose, optimal sampling pairs are at 1-1.5 hours (post-distribution) and 4-5 hours (elimination phase) [16]. This strategy minimizes bias from the distribution phase.

Frequently Asked Questions (FAQs)

Q1: What is the most robust experimental method for simultaneously estimating Vmax, Km, and CLint? A1: The Multiple Depletion Curves Method (MDCM) is highly robust [13]. It involves incubating multiple starting substrate concentrations with enzyme (e.g., liver microsomes) and measuring substrate depletion over time. The collective data from all curves are fitted to a Michaelis-Menten depletion model. This method is superior to the initial metabolite formation rate method for unstable metabolites and more accurate than the in vitro t½ method, especially when substrate concentration ([S]) is not << Km [14] [15].

Q2: How does sampling strategy specifically affect the accuracy of the Km parameter? A2: Km accuracy is highly sensitive to sampling the correct region of the reaction progress. Sampling that yields only initial rates or that includes too many points from the reaction plateau can distort the fit. The most accurate Km estimates come from data points located in the region of maximum curvature on the progress curve [11]. Using software that intelligently selects this region (or manually trimming data to focus on this phase) can significantly improve Km precision compared to fitting the entire curve.

Q3: Can I use a limited sampling strategy for pharmacokinetic parameters like AUC, and how do I choose the times? A3: Yes, limited sampling strategies are validated for estimating Area Under the Curve (AUC). The choice of times is critical and compound-specific. It requires prior knowledge of the compound's pharmacokinetics (distribution/elimination phases). For example, research on vancomycin shows that using two blood samples—one after the distribution phase (60-90 min post-infusion) and one during the elimination phase (240-300 min post-infusion)—provides an AUC estimate with less than 5% mean error [16]. The general principle is to sample after distribution equilibrium is reached and during the terminal log-linear elimination phase.

Q4: What are the key factors to optimize in my enzyme assay before worrying about sampling times? A4: Before optimizing sampling, you must first optimize the fundamental assay conditions to ensure a measurable, stable signal [17]. Key factors include:

- Enzyme Concentration: Use enough to generate a clear signal but avoid depletion of cofactors or excessive substrate turnover too quickly.

- Substrate Concentration: Should span a range from below Km to above Km (typically 0.2-5 x Km) for full characterization.

- pH and Buffer: Use the optimal pH for the enzyme and a buffer with adequate capacity.

- Temperature: Control tightly using a thermostated cuvette or heated incubator block.

- Detection System: Ensure the spectrophotometer or fluorometer is stable and that the measured signal (e.g., product formation) is within the linear range of the detector [12].

Comparison of Key Methodologies for Parameter Estimation

The choice of experimental and analytical method directly impacts the reliability of your kinetic parameters. The table below summarizes key approaches.

Table 1: Comparison of Methods for Estimating Enzyme Kinetic and Pharmacokinetic Parameters

| Method | Primary Use | Key Principle | Advantages | Disadvantages/Limitations | Impact of Poor Sampling |

|---|---|---|---|---|---|

| Initial Rate (IR) | Estimating Vmax, Km | Measures velocity at very early reaction times (<5% turnover) at various [S]. | Conceptually simple, linear phase. | Consumes more reagent; difficult for very fast/slow reactions; single point per reaction [11]. | Missing the true linear initial phase leads to systematic underestimation of velocity. |

| Full Progress Curve Fitting | Estimating Vmax, Km, kcat | Fits integrated rate equation to full time-course of product formation [11]. | Uses all data points; efficient with reagents. | Poor fits if plateau data dominates; requires robust fitting algorithms. | Sparse early sampling loses curvature information, crippling Km accuracy. |

| Multiple Depletion Curves (MDCM) | Estimating CLint, Vmax, Km [13] | Fits substrate depletion over time from multiple starting [S] to a depletion model. | Robust, works for low solubility compounds, corrects for enzyme loss. | More complex data analysis required. | Infrequent sampling misses depletion curve shape, increasing parameter error. |

| Limited Sampling & Bayesian Forecasting | Estimating PK parameters (AUC, CL) in patients [18] | Uses 1-3 plasma concentrations + a population PK model to estimate individual PK. | Minimizes patient blood draws; enables dose personalization. | Dependent on quality/appropriateness of the underlying population model. | Sampling during wrong phase (e.g., distribution) causes large AUC prediction errors. |

Detailed Experimental Protocols

Protocol 1: The Multiple Depletion Curves Method (MDCM) for Vmax, Km, and CLint [13] [14]

- Preparation: Prepare a master mix of enzyme source (e.g., human liver microsomes at 0.1-1 mg/mL protein) in appropriate buffer (e.g., phosphate, pH 7.4).

- Substrate Addition: Aliquot the master mix into multiple vials. Spike each vial with a different concentration of test substrate to create a range (e.g., 0.1, 0.3, 1, 3, 10 µM). Ensure concentrations bracket the expected Km.

- Incubation & Sampling: Start the reaction by adding cofactor (e.g., NADPH for CYP450). Immediately remove an initial time-zero sample (t0). Subsequently, sample each incubation vial at multiple predetermined time points (e.g., 1, 3, 5, 10, 20, 30, 45 min). Terminate the reaction in each sample immediately (e.g., with ice-cold acetonitrile).

- Analysis: Quantify remaining substrate concentration in all samples using LC-MS/MS or HPLC.

- Data Analysis: Fit the substrate depletion profiles from all starting concentrations simultaneously to the Michaelis-Menten depletion differential equation using nonlinear regression software (e.g., Phoenix WinNonlin, MATLAB, or R) to estimate Vmax and Km. CLint is calculated as Vmax/Km.

Protocol 2: Optimal Progress Curve Analysis for Km Determination [11]

- Run Reaction: Initiate a single reaction with substrate concentration [S]0 ≈ 2-5 x estimated Km. Use a plate reader or spectrophotometer to record product formation (Absorbance/Fluorescence) every 5-15 seconds until the reaction plateaus.

- Data Preprocessing: Correct for non-enzymatic reaction rates (run blank) and convert signal to product concentration.

- Identify Maximum Curvature: Use a dedicated tool like the iFIT algorithm or similar. The algorithm iteratively estimates the region of the progress curve with highest curvature, which is most informative for Km.

- Fit Integrated Equation: Fit the data points within the identified region of maximum curvature to an integrated Michaelis-Menten equation (e.g., using the Lambert W function approximation in GraphPad Prism). The fit will yield estimates for Km and Vmax.

- Validation: Compare the Km from this single-progress-curve method to one derived from a traditional initial rate experiment across multiple [S] for validation.

Visualization of Concepts and Workflows

Diagram: Optimal Sampling Regions on a Progress Curve

Diagram: Workflow for the Multiple Depletion Curves Method (MDCM)

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Enzyme Kinetic Studies

| Item | Function / Role in Experiment | Key Considerations for Optimal Sampling |

|---|---|---|

| High-Purity Recombinant Enzyme or Microsomes | Biological catalyst for the reaction. Source of enzyme activity. | Consistent activity between batches is critical for reproducible time-course data. Pre-check activity to determine appropriate protein concentration for assay linearity [12]. |

| Characterized Substrate(s) | Molecule converted by the enzyme. | Purity is essential. Stock concentration must be accurately known. Solubility limits the testable concentration range, affecting parameter estimation [14]. |

| Cofactors (e.g., NADPH for CYPs) | Provides essential reducing equivalents or chemical groups for catalysis. | Stability is key. Prepare fresh or use stable formulations to ensure consistent reaction initiation and velocity across all time points [13]. |

| Appropriate Buffer System | Maintains constant pH optimal for enzyme function. | Must have sufficient buffering capacity to withstand pH shifts during prolonged incubations, especially if sampling from the same vial repeatedly. |

| Stable Isotope-Labeled Internal Standards | For LC-MS/MS analysis of substrate or metabolite concentration. | Corrects for variability in sample extraction and instrument response, essential for accurate quantification of depletion or formation over time [14]. |

| Quenching Solution (e.g., Acid, Organic Solvent) | Instantly stops enzymatic reaction at precise sampling time. | Must be effective, compatible with the analytical method, and added in a consistent volume-to-sample ratio to avoid dilution errors affecting concentration measurements. |

| Thermostated Incubation System | Maintains constant temperature (e.g., 37°C). | Precise temperature control (<0.5°C variation) is non-negotiable, as kinetics are highly temperature-sensitive [12]. Affects all sampling time points equally. |

| Automated Liquid Handler | For precise, reproducible addition of reagents and sampling. | Minimizes timing errors during reaction initiation and sampling, which is crucial for generating accurate time-course data, especially for fast reactions. |

Technical Support & Troubleshooting Center

Welcome to the Technical Support Center for Enzyme Kinetic Studies. This resource is structured to address common experimental constraints—sample number, incubation duration, and substrate range—within the context of thesis research aimed at defining optimal sampling times for robust kinetic analysis. The following guides and protocols are designed to help researchers troubleshoot specific issues and implement best practices for generating reliable, publication-quality data.

Troubleshooting Guides & FAQs

Q1: My enzymatic reaction progress curves show inconsistent initial velocities, especially at low substrate concentrations. How can I improve reliability? A: This is a classic symptom of overlooking time-dependent inhibition or failing to achieve a proper pre-steady-state equilibrium. Conventional Michaelis-Menten analysis assumes rapid equilibrium binding, which is violated by inhibitors with slow association/dissociation rates [19].

- Root Cause: If an inhibitor (including some buffer components or impurities) has a long residence time (slow k_off), pre-incubating the enzyme and inhibitor may not suffice. The initial velocity measured after starting the reaction with substrate can still overestimate the true steady-state rate, making inhibition appear weaker (higher Ki) or altering the perceived inhibition type [19].

- Solution: Employ global fitting of full reaction progress curves instead of relying solely on initial velocities. This pre-steady-state analysis uses data from the entire time course to simultaneously determine kcat, Km, Ki, and the microscopic rate constants for inhibitor binding (kon) and dissociation (k_off) [19]. This method revealed that the potency of the Alzheimer's drug galantamine for acetylcholinesterase was historically underestimated by a factor of ~100 due to its slow-binding nature [19].

Q2: How do I decide between manual reagent addition and using an automated injector for my kinetic assay? A: The decision is dictated by the speed of your reaction kinetics [20].

- Use an Automated Injector (Essential) for: Reactions where signal (fluorescence/chemiluminescence) spikes and decays rapidly (seconds to a few minutes). Manual addition causes unacceptable delay, reducing sensitivity and distorting the reaction profile [20]. Examples include:

- Manual Addition (May be Acceptable) for: Slow, stable glow-type reactions where signal remains >70% after 1 hour. However, an injector still improves reproducibility [20].

- Critical Software Setting: For fast reactions, configure the reader in "well-by-well" or "single-kinetic" mode, where all steps (inject + read) are completed for one well before moving to the next. Using "whole-plate" mode for fast kinetics will cause significant signal loss between reads for different wells [20].

Q3: I need to capture transient enzymatic intermediates for mechanistic studies. What are the current best practices? A: Traditional endpoint methods fail to capture short-lived species. The state-of-the-art approach involves real-time, online monitoring coupled with mass spectrometry [21].

- Protocol: Real-time MS for Intermediate Capture (based on P450 catalysis study) [21]:

- Setup: Use a custom or commercial microfluidic/pressurized infusion setup to directly couple the reaction mixture to an ESI-MS source.

- Reaction Environment: Transfer the enzyme reaction into a volatile buffer compatible with MS (e.g., 500 mM ammonium acetate, pH 7.5). High buffer concentration is crucial for maintaining enzyme stability during analysis [21].

- Initiation & Monitoring: Initiate the reaction directly in the infusion vial (e.g., by adding H₂O₂). The MS continuously acquires data from the onset, monitoring the temporal evolution of substrate, intermediates, and product based on their m/z.

- Identification: Use tandem MS (MS/MS) to fragment detected ions and confirm the structures of proposed intermediates. Radical intermediates can be trapped and identified using markers like TEMPO [21].

- Advantage: This method allows for the temporal resolution of multiple intermediates, providing direct insight into the catalytic cycle, as demonstrated by the capture of five reactive intermediates in the oxidative dimerization of 1-methoxynaphthalene by CYP175A1 [21].

Q4: How many substrate concentration points are sufficient for a reliable kinetic study, and over what range? A: There is no universal number, but the goal is to define the curve robustly. Insufficient or poorly ranged points are a major constraint.

- Minimum & Range: Use a minimum of 8-10 substrate concentrations, spaced appropriately. The range should ideally bracket the Km by at least an order of magnitude on both sides (e.g., from 0.1 x Km to 10 x K_m).

- Practical Table: The following table summarizes key quantitative constraints from recent studies:

| Experimental Constraint | Recommended Practice / Observed Parameter | Impact & Rationale |

|---|---|---|

| Substrate Range | Should bracket Km widely (e.g., 0.1–10 x Km) | Defines the hyperbolic curve shape; points only near Km give poor estimates of Vmax [19]. |

| Sample Number (Replicates) | Minimum n=3 technical replicates; n>=6 for robust stats. | Accounts for pipetting and instrument noise. Low n increases error in parameter fitting. |

| Pre-Incubation Duration | Must be determined empirically for each inhibitor. | For slow-binders like galantamine, conventional pre-incubation may still be insufficient, requiring progress curve analysis [19]. |

| Data Point Density (Fast Kinetics) | Very short intervals (e.g., 10 ms for Aequorin) [20]. | Captures the true signal peak and decay profile; sparse sampling misses critical transient phases. |

| Real-time MS Sampling | Continuous monitoring from reaction initiation [21]. | Enables capture of intermediates with lifespans too short for discrete time-point quenching. |

Essential Experimental Protocols

1. Protocol for Detecting Time-Dependent Inhibition via Progress Curve Analysis [19]:

- Objective: To accurately determine K_i and microscopic rate constants for a slow-binding inhibitor.

- Procedure: a. Prepare a master mix of enzyme and inhibitor at various concentrations. Pre-incubate for a standardized time. b. Initiate reactions in a plate reader or spectrophotometer by adding substrate to achieve the desired final concentrations (spanning below and above Km). c. Record the entire progress curve (absorbance, fluorescence) for each well until the substrate is depleted or the rate is stable. d. Do not extract only initial velocities. Export the full time-course data for every well. e. Use specialized kinetic fitting software (e.g., KinTek Explorer) to globally fit all progress curves simultaneously to the appropriate kinetic model (e.g., competitive inhibition with slow binding). The model will directly output Km, Vmax, Ki, kon, and koff.

2. Protocol for Optimizing Instrument Settings for Kinetic Assays [20]:

- Objective: To configure a microplate reader for accurate kinetic data capture based on reaction speed.

- Procedure: a. Determine Reaction Speed: Run a preliminary test in "well-by-well" mode with an injector to see signal rise/fall time. b. Choose Read Mode: * Fast reactions (< 1 min to peak): Mandatory use of "Single Kinetic" or "Well Loop" mode. * Slow reactions (> 5 min stable signal): Can use "Whole Plate" mode. c. Set Timing: For a fast chemiluminescence reaction, use the shortest possible integration time (e.g., 10-100 ms) and minimal interval time between reads for the same well. d. Optimize Injector: Set a fast dispense speed for aqueous solutions to ensure rapid mixing without splashing.

Research Reagent Solutions & Essential Materials

| Item | Function & Importance in Kinetic Studies |

|---|---|

| High-Purity, MS-Compatible Volatile Buffers (e.g., Ammonium Acetate) [21] | Essential for real-time MS analysis of enzymatic reactions. Maintains enzyme stability (at high concentrations, e.g., 500 mM) while allowing efficient electrospray ionization. |

| Automated Microplate Reader with Integrated Injectors [20] | Critical for initiating fast kinetics without delay. Multi-injectors allow for complex multi-reagent assays. Enables "single-kinetic" well-by-well reading. |

| Slow-Binding/Time-Dependent Enzyme Inhibitors (e.g., Galantamine) [19] | Important pharmacological tools that necessitate advanced kinetic analysis (progress curve fitting) to avoid severe underestimation of potency. |

| Radical Trapping Agents (e.g., TEMPO) [21] | Used in conjunction with MS to trap and identify fleeting radical intermediates in catalytic cycles, elucidating reaction mechanisms. |

| Specialized Kinetic Modeling Software (e.g., KinTek Explorer) [19] | Enables global fitting of progress curve data to complex models, moving beyond the limitations of linear transformations and initial rate analysis. |

Visualization of Experimental Workflows

Diagram 1: Workflow for Real-Time MS Capture of Intermediates

Diagram 2: Decision Pathway for Pre-Incubation & Sampling Time

Frameworks in Action: Applying Optimal Experimental Design (OED) to Kinetic Assays

Principles of Optimal Experimental Design (OED) for Parameter Estimation

Welcome to the Technical Support Center for Optimal Experimental Design (OED) in Enzyme Kinetics. This resource is structured to assist researchers, scientists, and drug development professionals in implementing OED principles to improve the precision and reliability of parameter estimation (e.g., Vmax, Km, CLint) in high-throughput screening environments. The guidance below is framed within a thesis context focusing on optimizing sampling times and conditions to maximize information gain while respecting practical laboratory constraints [7] [1].

A core challenge in metabolic stability assays is designing experiments that yield high-quality parameter estimates from a limited number of samples. A standard design (STD-D) might use a single starting concentration (e.g., 1 µM) and arbitrary time points, potentially leading to high uncertainty. In contrast, OED uses statistical criteria to pre-select the most informative sampling times and substrate concentrations, minimizing the expected error in parameter estimates [7] [1].

Troubleshooting Guide: Common OED Implementation Issues

Issue 1: Poor Parameter Precision Despite Model Fitting

- Problem: Estimated enzyme kinetic parameters (Vmax, Km) have unacceptably high standard errors or wide confidence intervals, making results unreliable for decision-making.

- Diagnosis: This is often caused by a suboptimal experimental design where the chosen sample times and substrate concentrations do not provide sufficient information to distinguish between parameter values. For example, sampling only during the linear, initial phase of a reaction may preclude accurate estimation of Km [1].

- Solution: Implement a model-based OED prior to the experiment.

- Define a prior parameter distribution (e.g., from historical data on similar compounds) [7].

- Use OED software (e.g., PopED) to compute a design that maximizes a statistical criterion like D-optimality or ED-optimality, which minimizes the predicted covariance of parameters [22] [1].

- For a pragmatic design, consider a general optimal design (G-OD). One study found a G-OD using 15 samples, a starting concentration (C0) of 5 µM, and key samples at t=2, 10, and 40 minutes provided robust performance across many compounds [7].

Issue 2: Experimental Output Fails to Distinguish Between Rival Kinetic Models

- Problem: Data can be fitted almost equally well by different kinetic models (e.g., Michaelis-Menten vs. a mono-exponential decay), leading to ambiguous interpretation.

- Diagnosis: The design is not model-discriminating. It lacks measurements in critical regions where the predictions of the competing models diverge most significantly.

- Solution: Use an OED criterion focused on model discrimination.

- Formulate the competing models (e.g., full Michaelis-Menten for non-linear depletion vs. mono-exponential decay for linear conditions).

- Optimize the design to maximize the divergence between model predictions. This often involves sampling at time points where the substrate concentration is expected to be near or below the Km value, where non-linearity becomes apparent [1].

- The previously mentioned G-OD (C0=5 µM, samples at 2, 10, 40 min) inherently improves the ability to detect non-linear kinetics compared to a standard linear design [7].

Issue 3: Design is Theoretically Optimal but Practically Infeasible

- Problem: The computed optimal design suggests sampling at logistically impossible time points (e.g., too frequently) or requires unrealistic control over substrate concentration.

- Diagnosis: The optimization did not incorporate practical laboratory constraints.

- Solution: Perform a constrained optimization.

- Define all practical limits: maximum incubation time (e.g., 40 min), minimum interval between samples, available C0 range (e.g., 0.01 – 100 µM), and total sample number (e.g., 15) [7].

- Use these as hard boundaries in the OED algorithm. The output will be the best possible design within real-world limits. Studies show that even with such constraints, OED significantly outperforms standard designs [7].

Issue 4: High Uncertainty in Intrinsic Clearance (CLint) Estimates

- Problem: Estimates of metabolic intrinsic clearance (CLint = Vmax/Km) are inconsistent or have high variance, affecting predictions of in vivo hepatic clearance.

- Diagnosis: CLint is a derived parameter sensitive to error in both Vmax and Km. A design optimized for individual parameters may not be optimal for their ratio.

- Solution: Optimize the design directly for the precision of the CLint estimate.

- Use the penalized ED-optimal design approach. This method incorporates a prior distribution of likely Vmax/Km pairs and finds sampling times and C0 that minimize the expected standard error of CLint across this range [7] [1].

- Simulation studies demonstrate that such an OED generates better CLint estimates (lower relative standard error) for 99% of compounds compared to a standard design [7].

Frequently Asked Questions (FAQs)

Q1: What is the minimum number of samples required for reliable Michaelis-Menten parameter estimation using OED? A: While the minimum is 3 (for two parameters), reliability increases with more samples. A pragmatic OED study successfully used 15 samples total. The key is their strategic placement, not just their number. For instance, including a later time point (e.g., t=40 min) is crucial for accurately determining the depletion rate [7] [1].

Q2: How do I choose the starting substrate concentration (C0) for an optimal design? A: The optimal C0 depends on the prior estimate of Km. OED simulations show that a C0 of 5 µM often serves as a robust "general" optimum when Km is uncertain but expected to be in a low micromolar range. For a screening library, using this single optimized C0 is more efficient than trying to tailor C0 for each compound [7].

Q3: Can I use OED if I have no prior information about the enzyme's kinetic parameters? A: Yes, but it is less efficient. You can use a sequential or adaptive design. Run a small initial experiment with a space-filling design (e.g., a few samples across time and concentration). Use the results to form initial parameter estimates, then use OED to optimize the design for the remainder of the experiment. Novel OED criteria like the expected scaling effect are also being developed for such data-consistent inversion problems with minimal prior knowledge [22].

Q4: How much improvement can I expect from using an OED compared to my lab's standard protocol? A: Significant improvements are demonstrated. One study found an OED yielded high-quality estimates (RMSE < 30%) for both Vmax and Km for 26% of compounds, a result difficult to achieve with standard designs. Furthermore, it provided equal or better root mean square error (RMSE) in CLint estimation for 78% of compounds [7] [1].

Q5: Are there computational tools available to implement OED for enzyme kinetics? A: Yes. The study cited here used PopED (Population Optimal Experimental Design), a software tool for maximal likelihood estimation [1]. Other general statistical platforms (e.g., R, MATLAB) have packages for OED. The field is advancing with tools for novel criteria like expected skewness effect for stochastic inverse problems [22].

Protocol: Implementing a Pragmatic Optimal Design for Metabolic Stability Screening

This protocol is adapted from the referenced OED study for a high-throughput environment [7] [1].

Preparation:

- Compound:

- Prepare a 5 µM stock solution of the test compound in appropriate buffer. This C0 is the pragmatic general optimum.

- Enzyme:

- Use human liver microsomes (HLM) or recombinant CYP enzymes at a standardized protein concentration.

- Reaction Mixture:

- Combine microsomes, NADPH-regenerating system, and buffer. Pre-incubate for 5 minutes at 37°C.

- Replicate Strategy:

- Plan for n=15 analytical samples per compound.

Initiation & Sampling:

- Start the reaction by adding the compound stock solution.

- Immediately remove the t=0 min sample.

- Follow the optimized sampling scheme from the G-OD [7]:

- Critical Samples: Ensure you capture samples at approximately t=2 min, t=10 min, and t=40 min.

- Additional Samples: Distribute the remaining 11 samples across the 40-minute interval, with higher density in the early phase where change is most rapid.

- Stop each sample at its designated time by transferring it to a vial containing a quenching solution (e.g., acetonitrile with internal standard).

Analysis & Fitting:

- Analyze samples using LC-MS/MS to determine substrate concentration over time.

- Fit the depletion data to the Michaelis-Menten integrated equation using non-linear regression.

- Report estimates for Vmax (pmol/min/mg protein) and Km (µM), and calculate CLint (Vmax/Km, µL/min/mg).

Performance Data: OED vs. Standard Design

The following table summarizes quantitative outcomes from simulation studies comparing the Pragmatic Optimal Design (OD) to a Standard Design (STD-D) [7] [1].

Table 1: Comparison of Design Performance in Enzyme Kinetic Studies

| Performance Metric | Standard Design (STD-D) | Pragmatic Optimal Design (OD) | Improvement |

|---|---|---|---|

| Design Parameters | C0 = 1 µM; arbitrary time points | C0 = 5 µM; optimized times (e.g., 2, 10, 40 min) | Strategically informed |

| CLint Estimate Quality | Baseline | Better Relative Standard Error for 99% of compounds | Near-universal improvement |

| Vmax/Km Estimate Quality | Baseline | High-quality estimates (RMSE<30%) for 26% of compounds | Enables robust dual-parameter estimation |

| RMSE for CLint | Baseline | Equal or better for 78% of compounds | Majority of cases improved |

Visual Guides for Experimental Workflows

Diagram 1: OED Implementation Workflow for Enzyme Kinetics

Workflow for Optimal Enzyme Kinetic Design

Diagram 2: Decision Tree for Troubleshooting Parameter Estimation

Diagnosing Poor Parameter Estimates

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for OED in Enzyme Kinetics

| Item | Function in OED for Enzyme Kinetics | Key Consideration for OED |

|---|---|---|

| NADPH Regenerating System | Provides constant cofactor supply for CYP450 enzymes. Essential for maintaining consistent reaction velocity over the incubation period. | Depletion must be prevented to avoid introducing an unintended time-dependent variable. |

| Human Liver Microsomes (HLM) | Source of metabolic enzymes. The enzyme concentration ([E]) must be known and consistent. | Fixed total enzyme is a core constraint in OED and optimization frameworks for catalytic efficiency [23]. |

| LC-MS/MS System | Analytical platform for quantifying substrate depletion over time with high sensitivity and specificity. | Must be capable of processing the number of samples specified by the design (e.g., 15/time course) with high precision. |

| Optimal Design Software (e.g., PopED) | Computational tool to perform ED-optimal or D-optimal design calculations based on a model and constraints. | Requires a defined pharmacokinetic model (e.g., Michaelis-Menten) and practical constraints as input [1]. |

| Substrate Stock Solutions | Prepared across a range of concentrations (e.g., 0.01-100 µM) for design exploration. | The starting concentration (C0) is a primary optimization variable in OED to ensure informative data [7]. |

| Mixed-Integer Linear Program (MILP) Solver | Advanced computational tool for exploring optimal enzyme operation modes under thermodynamic constraints. | Used in frameworks like OpEn to assess optimal kinetic parameters from an evolutionary perspective, informing prior distributions [23]. |

Technical Support Center: Troubleshooting & FAQs for Optimal Sampling in Enzyme Kinetics

This technical support center addresses common challenges researchers face when applying Fisher Information Matrix (FIM) and Cramer-Rao Lower Bound (CRB) analysis to design optimal experiments for enzyme kinetic parameter estimation. The guidance is framed within a thesis on optimizing sampling times to enhance the precision of estimates for parameters like the maximum reaction rate (Vₘₐₓ) and the Michaelis constant (Kₘ) [24] [25].

Troubleshooting Guide: Common Experimental Challenges

Q1: My parameter estimates have unacceptably high variance. How can FIM analysis help me design a better experiment?

- Problem Identification: High variance in parameter estimates (e.g., for Vₘₐₓ and Kₘ) often stems from suboptimal experimental design, such as poorly chosen substrate concentrations or sampling times [24].

- FIM/CRB Solution: The FIM quantifies the amount of information an experiment provides about the parameters. Its inverse sets a lower bound (the CRB) on the covariance matrix of any unbiased estimator [26]. By calculating the FIM for a proposed experimental design (e.g., a set of substrate concentrations and measurement times), you can predict and minimize the expected variance before running the experiment.

- Protocol: 1) Formulate your kinetic model (e.g., Michaelis-Menten). 2) Propose a candidate experimental design (e.g., 10 sampling points). 3) Compute the FIM for this design using initial parameter estimates. 4) Use an optimality criterion (like D-optimality, which maximizes the determinant of the FIM) to adjust the design—such as shifting sampling times—to minimize the predicted parameter variances [24] [25].

Q2: Should I use a batch or a fed-batch reactor setup for the most precise parameter estimation?

- Problem Identification: A standard batch experiment may not provide sufficient information, especially for estimating Kₘ, if the substrate depletion profile is not informative enough [24].

- FIM/CRB Solution: Analytical analysis of the FIM demonstrates that a fed-batch process with controlled substrate feeding can significantly improve estimation precision compared to a simple batch experiment [24].

- Protocol: Implement a fed-batch design where substrate is added at a low, constant flow rate. This maintains a dynamic range of substrate concentration over a longer period. Simulations based on FIM analysis show this method can reduce the lower bound on the variance of the estimation error to approximately 82% for Vₘₐₓ and 60% for Kₘ compared to standard batch values [24].

Q3: How do I choose the best substrate concentrations and sampling times when my initial parameter guesses are poor?

- Problem Identification: Optimal design based on the FIM requires nominal parameter values, but these are initially unknown [24].

- FIM/CRB Solution: Employ a sequential (two-stage) experimental design strategy.

- Protocol:

- Initial Exploratory Experiment: Conduct a first experiment using a broad, geometrically spaced range of substrate concentrations to collect initial data [24].

- Preliminary Estimation: Fit your model to this data to obtain rough parameter estimates.

- FIM-Based Optimization: Use these rough estimates as nominal values to compute the FIM and identify the D-optimal sampling points for the next experiment [24] [25].

- Refined Experiment: Execute the optimized design to obtain high-precision final estimates.

Q4: My experimental reaction rate data is inherently positive and heteroscedastic. Does the assumed error structure impact the optimal design?

- Problem Identification: Assuming an additive, constant-variance normal error for positive rate data can lead to negative simulated values and suboptimal design points, especially when variance increases with the mean rate [25].

- FIM/CRB Solution: Model the error structure more appropriately, such as a multiplicative log-normal error. This transforms the problem to a linear scale where standard assumptions hold (

ln(rate) = ln(model) + normal error) [25]. - Protocol: 1) Log-transform both your kinetic model and your observed rate data. 2) Perform parameter estimation and FIM-based optimal design (e.g., D-optimal design) in the log-transformed space. This ensures designs are optimal for the actual error distribution and prevents faulty negative predictions [25].

Frequently Asked Questions (FAQs)

Q: What is the direct, practical relationship between the FIM and the Cramer-Rao Bound?

A: The FIM (I(θ)) measures the sensitivity of your observable data to changes in the model parameters (θ). The CRB states that the inverse of the FIM provides a lower limit for the variance (or covariance matrix) of any unbiased parameter estimator [26]. In practice, an experimental design that maximizes the FIM (e.g., by maximizing its determinant) minimizes this lower bound, giving you the theoretically most precise estimates possible from that experimental setup.

Q: What is a "D-optimal" design, and why is it commonly used? A: A D-optimal design is one that maximizes the Determinant of the Fisher Information Matrix. Maximizing the determinant minimizes the volume of the confidence ellipsoid around the parameter estimates. It is a widely used criterion for optimizing experiments for precise parameter estimation in nonlinear models, including enzyme kinetics [24] [25].

Q: Can optimal design help choose between rival kinetic models, like competitive vs. non-competitive inhibition? A: Yes. Beyond parameter estimation (using criteria like D-optimality), optimal design principles can be applied for model discrimination. Criteria like T-optimality or Ds-optimality are used to design experiments that maximize the power to distinguish between two or more candidate mechanistic models (e.g., competitive vs. non-competitive inhibition), which is crucial in drug discovery [25].

Q: Are the benefits of fed-batch design for parameter estimation always guaranteed? A: The analysis in [24] shows that substrate feeding is favorable, but enzyme feeding is not. The improvement is also dependent on implementing an appropriate, low-volume flow rate. The specific gains (e.g., variance reduction to 82% and 60% for Vₘₐₓ and Kₘ) are benchmark examples and can vary based on your specific kinetic system and constraints.

The table below summarizes core quantitative results from FIM-based analysis for designing enzyme kinetic experiments.

| Experimental Design Strategy | Key Finding from FIM/CRB Analysis | Practical Implication for Parameter Estimation |

|---|---|---|

| Fed-Batch vs. Batch [24] | Fed-batch with substrate feeding reduces the lower bound on variance to 82% for Vₘₐₓ and 60% for Kₘ compared to batch. | Significantly more precise estimates of Kₘ and Vₘₐₓ can be achieved by controlling substrate addition. |

| Optimal Sample Point Selection [24] | For constant measurement error, high information is obtained at extreme substrate concentrations: the maximum attainable (Cmax) and at C₂ = (Kₘ * Cmax)/(2Kₘ + C_max). | Allocate a significant portion of your measurements at the highest feasible substrate concentration and at this calculated lower concentration. |

| Error Structure Consideration [25] | Assuming multiplicative log-normal error (instead of additive normal) changes the location of optimal design points, ensuring non-negative rate predictions and efficiency. | Always validate or test the error structure of your data. Using the wrong model for error can lead to a suboptimal design and invalid simulations. |

Detailed Experimental Protocol: FIM-Based Optimal Sampling Time Determination

This protocol outlines the steps to determine optimal sampling times for a Michaelis-Menten kinetic study in a fed-batch reactor.

Objective: To identify sampling times t_i that minimize the predicted variance of Vₘₐₓ and Kₘ estimates.

Materials: (See "The Scientist's Toolkit" section below). Pre-requisite: Initial rough estimates of Vₘₐₓ and Kₘ from literature or a preliminary experiment.

Procedure:

- Define the Dynamic Model: Use the differential equation for substrate consumption:

dS/dt = - (Vₘₐₓ * S) / (Kₘ + S). - Define the Measurement Model: Specify that you will measure substrate concentration

S(t)at timest_i. - Formulate the Parameter Sensitivity Equations: Calculate the partial derivatives of the state

S(t)with respect to each parameter (Vₘₐₓ and Kₘ). These sensitivities describe how each measurement changes as a parameter changes and are the building blocks of the FIM. - Compute the Fisher Information Matrix (FIM): For a set of

Nproposed sampling times{t₁, t₂, ..., t_N}, the FIM is calculated by integrating the sensitivity functions over time and summing the information contribution from each planned sample [24]. The FIM is a 2x2 matrix for parameters (Vₘₐₓ, Kₘ). - Apply an Optimality Criterion & Optimize: Use the D-criterion. The goal is to adjust the sampling times

t_ito maximize the determinant of the FIM. This is a numerical optimization problem that can be solved using software algorithms (e.g., sequential quadratic programming, genetic algorithms) [24]. - Validate with CRB: Calculate the inverse of the optimized FIM. The diagonal elements of this inverse matrix are the Cramer-Rao lower bounds for the variance of Vₘₐₓ and Kₘ. Use these values to predict the best possible precision your optimized experiment can deliver.

Visualizing the Workflow and Logic

The following diagrams illustrate the core logical relationship and the specific experimental workflow for implementing FIM-based optimal design.

Diagram: Logic of Optimal Experiment Design via FIM & CRB Analysis.

Diagram: Workflow for Determining Optimal Sampling Times.

The Scientist's Toolkit: Essential Research Reagents & Materials

The following reagents and tools are essential for executing enzyme kinetic studies designed via FIM analysis.

| Item | Function in Experiment | Key Consideration for Optimal Design |

|---|---|---|

| Target Enzyme | Biological catalyst; its concentration ([E₀]) is a fixed initial condition in the kinetic model [24]. | Purification level and stability directly affect the signal-to-noise ratio, impacting error variance (σ²). |

| Substrate (S) | The molecule converted by the enzyme; its concentration ([S]) is the primary manipulated design variable [24] [25]. | The range ([S]min to [S]max) must span from well below to above the estimated Kₘ to inform the model. For fed-batch, a stock solution for feeding is required [24]. |

| Inhibitor (I) (Optional) | A molecule that reduces reaction rate; used in inhibition studies [25]. | Its concentration ([I]) becomes a second design variable for models like competitive inhibition. |

| Analytical Instrument (e.g., Spectrophotometer, HPLC) | Measures product formation or substrate depletion over time to determine reaction rate (v). | Measurement frequency and noise characteristics define the error structure (additive vs. multiplicative), which is critical for correct FIM calculation [25]. |

| Fed-Batch Bioreactor | System allowing controlled addition of substrate (or inhibitor) during the reaction [24]. | Enables implementation of dynamic optimal designs predicted by FIM analysis to maintain informative substrate levels. |

| Statistical Software (e.g., R, MATLAB, Python with SciPy) | Platform for nonlinear regression, sensitivity analysis, FIM computation, and numerical optimization of designs [24] [25]. | Essential for performing the calculations that translate the FIM/CRB theory into a practical experimental plan. |

Technical Support & Troubleshooting Center

This support center is designed for researchers applying optimal experimental design (OED) to enzyme kinetic studies and drug metabolism screening. It addresses common computational and practical challenges, framed within a thesis investigating optimal sampling times for precise parameter estimation.

Troubleshooting Guides

Guide 1: Resolving High Parameter Uncertainty in D-Optimal Designs

- Problem: After running a D-optimal designed experiment for Michaelis-Menten kinetics, the confidence intervals for your estimated Km and Vmax are unacceptably wide.

- Diagnosis: This typically indicates a poorly conditioned Fisher Information Matrix (FIM). The D-optimal criterion maximizes the determinant of the FIM, but the result is highly sensitive to the initial parameter guesses used for the design calculation [24]. Your initial guesses may be too far from the true values.

- Solution:

- Iterative Design: Use a sequential design approach. Conduct a small initial experiment (e.g., 3-4 data points spaced widely).

- Re-estimate: Fit the preliminary data to obtain updated parameter estimates.

- Re-optimize: Re-calculate the D-optimal sampling times and substrate concentrations using the updated estimates as new priors [24].

- Proceed: Run the next batch of experiments at the newly optimized points. This sequential process improves the local optimality of the design.

Guide 2: Handling Noisy or Unreliable Data in ED-Optimal Screening

- Problem: In a high-throughput screening environment using an ED-optimal design, data from some compounds shows high variability or non-monotonic depletion, making CLint estimation unreliable.

- Diagnosis: The ED-optimal design is robust to parameter uncertainty but assumes the underlying model (e.g., Michaelis-Menten or monoexponential decay) is correct [7] [1]. Noisy data can stem from technical issues (e.g., pipetting error, poor plate sealing) or model misspecification (e.g., substrate inhibition, enzyme activation).

- Solution:

- Technical Audit: Follow a systematic troubleshooting protocol [27]. Verify instrument calibration, reagent freshness (especially co-factors like NADPH), and incubation conditions (temperature, humidity).

- Control Check: Ensure positive and negative control compounds are performing as expected within the same assay plate.

- Model Diagnosis: Plot the depletion curve. If visual inspection suggests a departure from simple exponential or hyperbolic decay, the design may be inadequate. A pragmatic solution is to flag the compound for follow-up with a more tailored, resource-intensive design.

Guide 3: Algorithmic Failure in Optimal Design Computation

- Problem: The optimization algorithm (e.g., in software like PopED) fails to converge when searching for optimal sample times and concentrations.

- Diagnosis: The optimization problem is non-convex and may have multiple local optima. Failure can occur due to unrealistic parameter bounds, poorly scaled variables, or numerical instability in calculating the FIM [28].

- Solution: